Labeling glass surfaces introduces unique challenges, including smoothness, non-porosity, and the need for optical clarity. Variations in glass types, such as tempered or borosilicate glass, impact label adhesion and visibility. Industries like pharmaceuticals, labware, and architecture demand labeling solutions that maintain clarity, withstand temperature changes, and ensure reliable identification.

Glass is a smooth, non-porous material known for its clarity, chemical resistance, and brittleness. While its surface should theoretically allow for strong adhesive bonding, challenges arise due to its need for optical clarity and the potential for temperature-induced expansion and contraction. Additionally, the variety of glass types, from borosilicate to tempered glass, introduces further complexity in ensuring labels adhere effectively without compromising visibility.

Glass has a relatively high surface energy, which should improve bonding, but its non-porous nature can negate this advantage.

The smooth surface limits the ability of adhesives to penetrate or grip, often requiring specially formulated adhesives.

Labels on glass must be carefully placed to maintain optical clarity and avoid obstructing sensors or other equipment.

Labels on glass must resist a range of environmental factors, including chemicals, UV light, and temperature fluctuations.

Labeling glass surfaces requires careful consideration of several factors to ensure strong, lasting adhesion. Glass’s high surface energy can aid in bonding, but only if the adhesive is formulated to wet out effectively, making uniform contact with the smooth, non-porous surface. The adhesive’s viscosity, chemical composition, and initial tack are all critical in preventing labels from sliding or failing to adhere.

Selecting the right adhesive—whether it’s acrylic, acrylic emulsion, acrylic solvent, or rubber-based—depends on how the label will be used and the specific demands of the application. Each formulation offers different benefits, and ensuring compatibility with the glass surface is key to achieving optimal performance. Our expertise allows us to construct the right label for every situation.

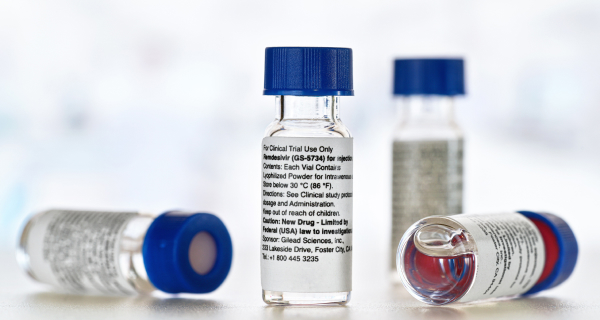

Glass labeling is crucial in industries like pharmaceuticals, biotechnology, and research laboratories. These sectors require durable and precise labeling solutions for vials, labware, and glass containers to ensure accurate sample tracking and compliance with regulatory standards. Reliable labeling helps maintain the integrity and traceability of critical samples.

Glass labware, such as test tubes, beakers, and flasks, demands labels that can endure harsh conditions, including exposure to chemicals, autoclaving, and freezing temperatures.

Labels must provide clear identification without obstructing critical measurements or sensor readings.

Specialized adhesives are often required to ensure labels adhere properly to smooth, non-porous glass surfaces, even in demanding environments.

Glass vials and containers used in chromatography must endure extreme conditions, including exposure to solvents and temperature variations.

Ensuring that labels remain securely attached and legible, even in these challenging conditions, is critical for sample identification and traceability.

Adhesives must be specifically formulated to perform in these demanding environments, where reliable labeling is essential for maintaining sample integrity.

Glass components such as instrument panels, and windows require labels that can withstand extreme temperatures, UV exposure, and pressure changes.

These labels must adhere securely to smooth glass surfaces and remain legible throughout the lifespan of the aircraft.

Ensuring that labels can endure the demanding conditions of aerospace applications is essential for safety and regulatory compliance.

Key regulations impacting glass labeling include FDA 21 CFR Part 175.105, which governs the safety of adhesives used on labels for glass containers, particularly those in contact with food and pharmaceuticals. ISO 15378 provides guidelines for Good Manufacturing Practices (GMP) for glass used in pharmaceutical packaging, ensuring labels remain intact and legible throughout the product’s lifecycle.

In the EU, Regulation (EC) No 1935/2004 mandates that labeling materials do not release harmful substances into food. Compliance with these regulations, along with any specific OEM requirements, is essential for ensuring safety, durability, and performance in glass labeling. Compliance with these regulations and standards is essential for ensuring safety, durability, and performance in glass labeling.

Labels for glass require precise engineering to achieve strong adhesion on smooth, non-porous surfaces. The right adhesive and face stock combination ensures durability and clarity, especially in environments with temperature fluctuations and chemical exposure. Understanding these factors is essential for creating reliable labeling solutions.

We maintain a comprehensive inventory of solvents, acids, bases, and industrial chemicals for material testing.

T-peel, 180-degree peel, and shear tests are crucial for evaluating how well labels stick to metal surfaces.

Our advanced equipment is capable of testing label performance fom as low as -296°C all the way up to 600°C.

We use the Taber abrader to help us determine how well labels materials can withstand wear and tear in demanding environments.

Our label materials for glass surfaces are designed to provide strong adhesion and clarity, even on smooth, non-porous surfaces. We use advanced adhesives and face stocks to ensure that labels remain securely attached and legible in environments where temperature fluctuations and chemical exposure are common.

For glass products, we provide advanced marking and labeling solutions that offer greater permanence and durability than traditional adhesive labels. These techniques are particularly suited for glass labware, vials, and other items that must endure harsh environments, sterilization processes, and repeated handling. By integrating labels directly into or onto the glass surface, we ensure that the identification remains clear and intact throughout the product’s lifecycle.

These methods are designed to withstand chemical exposure, thermal shocks, and physical abrasion, making them ideal for applications where long-term durability is essential. If your glass products require specialized marking solutions, contact us to explore the options we can offer.

Ensure our labeling solutions meet your glass product requirements. Submit your information to qualify our materials for your specific applications.

Chromatography labels provide clear identification for samples in complex workflows. They withstand exposure to solvents and high temperatures.

Histology slide labels withstand staining and chemical processes. They provide clear identification through critical diagnostic procedures.

Cryo labels remain durable in extreme cold conditions. Ideal for long-term storage of samples at ultra-low temperatures.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields