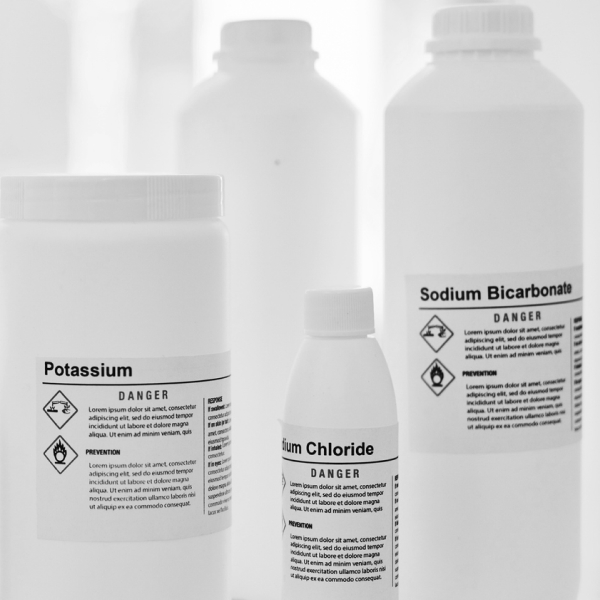

Protect your workplace and employees by clearly identifying hazardous materials and ensuring adherence to safety regulations. Our hazard communication labels are designed to withstand harsh environments, ensuring that vital safety information remains visible and legible at all times. Industries ranging from manufacturing to laboratories can rely on our solutions for their critical safety needs.

Hazard communication labels are essential tools for identifying and communicating the dangers associated with hazardous chemicals. These labels provide critical safety information, ensuring that workers and handlers are aware of potential risks and know how to protect themselves. They are a key component of workplace safety and regulatory compliance, used across various industries to prevent accidents and injuries.

Achieving effective hazard communication requires selecting the right type of label for your specific environment and ensuring that all necessary information is clearly displayed. Labels must be durable, able to withstand exposure to chemicals, moisture, and other harsh conditions while remaining legible.

Different regulations, such as GHS, OSHA, and DOT, dictate the specific requirements for hazard labels, making compliance a key aspect of effective labeling. Standardization across these labels is essential, as it ensures that hazard information is consistently communicated, reducing the risk of misunderstandings. By adhering to these regulations businesses can ensure they are meeting legal requirements and protecting their workforce from potential hazards.

Our GHS labels are essential for companies that operate in multiple countries, ensuring that hazard communication is consistent and compliant with international regulations. These labels feature universally recognized symbols, signal words, and hazard statements, making them easily understandable.

Materials resist chemicals, abrasion, and environmental factors.

Our OSHA-compliant labels are essential for maintaining a safe and compliant workplace. Designed to meet the Hazard Communication Standard (HCS), these labels provide clear instructions and warnings about chemical hazards. With easy-to-read formats and durable materials, our OSHA labels ensure that your employees are well-informed and protected, helping you avoid regulatory penalties and enhance workplace safety.

HMIS labels are crucial for internal hazard communication within your facility. These labels use a simple, color-coded system to identify health, flammability, and physical hazards, making them easy for employees to understand at a glance. Our HMIS labels are durable and customizable, ensuring they remain visible and effective in conveying safety information, even in challenging industrial environments.

DOT labels are critical for the safe and compliant transportation of hazardous materials. These labels feature standardized symbols and color codes that communicate the specific risks associated with each material, ensuring safe handling during transit. Our DOT labels are designed to withstand the rigors of transportation, ensuring that your shipments remain clearly marked and compliant with Department of Transportation regulations.

Choosing the right materials and printing methods is critical for the effectiveness of HazCom labels. The durability of the label, its legibility, and its ability to communicate essential safety information all depend on selecting the appropriate materials and design elements. Understanding these factors ensures that your labels remain compliant, readable, and durable across various environments and applications.

Choosing the right material for your hazard labels ensures they withstand harsh conditions. Polyester and vinyl are popular choices for environments that involve exposure to chemicals, moisture, or extreme temperatures, as they offer excellent durability and resistance to degradation. Adhesives are equally important, as they ensure the label remains securely attached to surfaces, even in harsh conditions.

The choice of material and adhesive should be tailored to the specific needs of your industry, taking into account factors like surface type, exposure to chemicals, and environmental conditions. Properly selecting these components not only helps maintain the label’s integrity but also ensures that critical safety information remains visible and compliant with regulatory standards.

Hazard communication labels convey critical details that help workers understand the risks and take appropriate precautions. Each element on the label serves a specific purpose, from identifying the chemical to describing the hazards and necessary safety measures. By clearly communicating this information, hazard labels play a vital role in protecting employees and maintaining regulatory standards.

Standardized symbols or pictograms visually represent the nature of the hazard, such as a flame for flammability or a skull and crossbones for toxicity. These icons ensure that the hazard is understood.

Colors quickly indicate the type of hazard, making it easier for workers to identify risks at a glance. For example, red might signal flammability, while blue could denote health hazards.

Proper storage and management of hazardous chemicals are essential for maintaining a safe and compliant workplace. Key aspects of safe chemical storage include the segregation of incompatible substances, controlling access to storage areas, and using appropriate storage containers. Our LabTrack™ Software is designed to help you effectively manage these critical safety measures.

Proper segregation and access control are vital to safely managing hazardous chemicals in any workplace. Incompatible chemicals must be stored separately to prevent dangerous reactions, which could lead to fires, explosions, or toxic releases. Additionally, access to these materials should be restricted to trained and authorized personnel to reduce the risk of accidental exposure or misuse.

Asset tracking software simplifies these processes by categorizing chemicals based on their hazard class and managing who can access storage areas, ensuring compliance with safety standards and regulations. Effective segregation and access control are more than just regulatory requirements. By prioritizing these elements, you can safeguard your employees and protect your facility.

Different industries face unique challenges when it comes to hazard communication, requiring tailored labeling solutions. Customizing hazard communication labels ensures that industry-specific hazards are clearly communicated and regulatory requirements are met. From manufacturing to healthcare, effective labeling is key to maintaining safety and compliance across diverse environments.

Hazard communication requirements can vary significantly across different industries, for example, chemical manufacturing might require detailed chemical symbols and specific precautionary statements, while the healthcare industry may need multi-language labels to accommodate diverse staff and patient populations.

In the transportation and logistics sector, labels often need to meet both GHS and DOT standards, ensuring safe handling and compliance during transit. Customizing HazCom labels to fit these specific industry needs not only enhances safety but also ensures that all regulatory requirements are met. By tailoring labels to the unique hazards and environments of your industry, you can improve the clarity and relevance of hazard communication, reducing the risk of accidents.

In chemical manufacturing, hazard communication labels must withstand exposure to corrosive substances, solvents, and extreme temperatures. These labels are essential for identifying chemical hazards, ensuring that workers are aware of potential risks and proper handling procedures. Compliance with GHS and OSHA standards is crucial, as these labels must clearly communicate the dangers associated with each substance.

Laboratories require hazard communication labels that endure frequent contact with a variety of chemicals and solvents. Labels must remain legible and intact to ensure accurate identification of hazardous substances and proper safety protocols. Adhering to GHS and other regulatory standards, these labels help protect lab personnel by providing clear warnings and instructions, ensuring a safe working environment.

In the automotive industry, hazard communication labels must resist exposure to fuels, oils, and harsh cleaning agents. These labels play a vital role in conveying safety information related to chemicals used in vehicle manufacturing and maintenance. Meeting GHS and OSHA requirements, they ensure that workers handle materials safely, reducing the risk of accidents and maintaining compliance with safety regulations.

Ready to improve your safety labeling with hazard communication labels? Fill out the form below, and our team will help you get started.

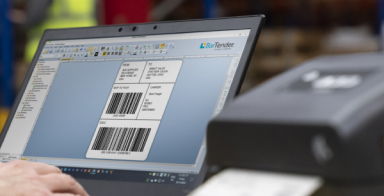

BarTender makes label design and printing simple and efficient. Integrate easily with agricultural systems for compliance and tracking.

The cab Squix printer delivers precise, high-quality label printing for various applications. It combines versatility and reliability to meet demanding needs.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields