Ensure your products withstand the heat with labels engineered for high-temperature environments. Our high heat labels are crafted to endure intense conditions without compromising on performance or readability. Ideal for industries ranging from automotive to aerospace, these labels maintain adhesion and clarity even in the most demanding applications.

High heat labels are essential for products that must withstand extreme temperatures. Whether in manufacturing, processing, or end-use environments, these labels are designed to maintain their integrity and readability under intense heat. From automotive components to electronic parts, these labels are engineered to meet rigorous thermal demands.

Effective high heat labels are built with materials and adhesives that resist thermal degradation and maintain adhesion even under extreme conditions. These labels are designed to survive processes such as curing, soldering, and autoclaving without losing functionality.

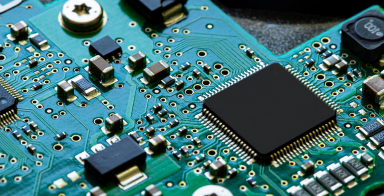

Surface-mount technology exposes labels to fast, intense thermal spikes during reflow oven passes.

Reflow soldering also creates intense short-term thermal spikes during surface-mount electronics production.

Polyimide films and heat-stable adhesives protect traceability through high-temp processing and board washing.

Vulcanization combines heat, time, and pressure to crosslink rubber in tire and automotive components.

Labels applied pre-cure must withstand the full vulcanization cycle without delaminating or degrading.

Engineered constructions preserve data integrity through chemical exposure, heat, and compression.

Common in labs and healthcare, autoclaves operate at 121–135°C under high steam pressure.

Labels must bond to wet or curved surfaces without smearing, peeling, or fading post-cycle.

Material and adhesive selection ensures readability and traceability through repeated sterilization exposure.

Automotive parts often enter paint or powder coating lines, then bake at high heat to cure finishes.

Labels must resist bubbling, discoloration, and adhesive bleed during elevated oven temperatures.

Durable films and heat-stable topcoats preserve barcode readability through curing and finishing stages.

Processes like sintering, forging, and annealing expose parts to 400°C–600°C+ thermal environments.

Labels must resist oxidation, shrinkage, or adhesive failure under intense, sustained radiant heat.

Specialized films and cured coatings allow traceability through the most punishing thermal cycles.

Test your toughest process—request a high heat label sample engineered to endure extreme temperatures, curing lines, and thermal shock.

Choosing the right label material for extreme cold storage is crucial to maintaining the integrity and traceability of your samples. Our specialized label materials are designed to perform reliably in the harshest conditions, from ultra-low temperature freezers to vapor and liquid nitrogen storage.

Thermal transfer materials rated for heat exposure pair with compatible ribbons and printers to withstand elevated temperatures during use, testing, or storage.

Durable, customizable pre-printed labels resist image degradation under high heat and maintain readability where traditional thermal transfer imaging would fail.

Pre-marked labware, produced using advanced marking technologies, offers enhanced durability, especially for glass labware with fused or ceramic bonded labels.

High heat materials resist discoloration during oven curing or soldering, maintaining barcode contrast for accurate scanning.

High-temperature adhesives remain stable under continuous exposure to heat—preventing slide, ooze, or adhesive failure.

Pre-printed labels using UV-cured inks resist heat-related image distortion, preserving clarity through prolonged or extreme heat exposure.

We build high heat labels using stable face stocks like polyimide and high-temp polyesters, paired with heat-resistant adhesives. Constructions are designed to remain intact at continuous temperatures above 300°F, with options that withstand even higher peaks during curing, soldering, or processing.

Labels are tested across a range of operating and peak temperatures, including sustained exposure and thermal cycling. We validate adhesive hold, material stability, and image integrity under real production conditions to ensure consistent performance.

Thermal transfer is a common method for high heat applications, especially when paired with resin ribbons designed for extreme conditions. We guide material and ribbon selection to ensure printed data stays intact through ovens, hot surfaces, or direct contact with heated components.

For long-term heat exposure, we offer pre-printed solutions using cured inks and abrasion-resistant finishes. Our production systems support serialized sets, small text, and high-contrast imaging—engineered for high-visibility labeling in manufacturing, aerospace, and electronics environments.

Sterilization-safe labeling doesn’t stop with the label itself—it’s about making sure your workflow, print process, and hardware all align. Our label solutions are compatible with a wide range of printing systems, including thermal transfer printers, laser printers, and fully automated label applicators. If you’re printing in-house, we’ll guide you toward face stocks and coatings that match your specific printer model, ribbon type, and print resolution needs.

In labs and cleanrooms where sterilization is required, hardware selection often impacts label durability. For instance, thermal transfer printing combined with resin ribbons offers enhanced chemical and heat resistance—critical for autoclave or chemical sterilant workflows. When automation is part of the process, we ensure label materials meet the physical requirements of robotic handling, high-speed printing, or tight label tolerances. No matter how you’re printing—whether it’s a single workstation or a full-scale automation line—our labels are designed to work with your equipment, not against it.

Thermal exposure testing reaches up to 600°C to simulate extreme environments. We validate label integrity through cycles of dry heat, autoclave steam, and other heat sources. Testing ensures labels retain adhesion, remain legible, and resist discoloration at elevated temperatures.

Labels exposed to high temperatures need more than basic heat resistance—they require engineered materials that remain legible, bonded, and stable. Our high heat label solutions are used in automotive, electronics, metalworking, and other manufacturing settings where exposure to ovens, soldering, or curing is routine. We help match the right construction to your process, ensuring durability under real operating conditions.

We support labeling for ovens, soldering, curing, and more—where consistent performance at 300°F and beyond is essential.

Our constructions use time-tested polyimides, polyesters, and adhesives designed to survive long-term exposure to elevated temperatures.

We help identify the right materials and construction to ensure high heat durability without overbuilding or sacrificing performance.

Not all labels are built the same. Share a few details about your product or environment, and we’ll recommend a label designed to stick, stay readable, and hold up under pressure.

High heat labels are essential for tracking and identification in extreme manufacturing and laboratory conditions. These labels resist heat that would typically degrade adhesives or destroy printed images. Industries rely on them to maintain traceability through high-temperature exposure, ensuring compliance and efficiency.

From electronics manufacturing to automotive and aerospace, high heat labels serve a critical role in protecting data and preventing relabeling. These labels support efficiency during processes like soldering, curing, and autoclaving. Performance depends on choosing the right construction for your specific heat and chemical exposure.

Endure solder reflow and wave soldering. Labels must survive over 250°C while staying legible and securely bonded throughout production.

Carry pre-cure labels through vulcanization. Materials must withstand heat, pressure, and surface changes without peeling or fading.

Move through powder coat ovens. Labels need to resist baking temperatures and allow reliable scanning after post-paint inspection and assembly.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields