Ensure your products remain clearly identified and traceable, even in the harshest cold storage environments. Withstand extreme cold, moisture, frost, and liquid nitrogen without losing adhesion or readability. Industries from biobanks to logistics rely on our solutions to protect their inventory. With durable materials and advanced adhesives, these labels maintain performance through freeze-thaw cycles and long-term storage.

Labeling for cold storage involves unique requirements that ensure the integrity and traceability of products. Extreme temperatures, moisture, frost, and repeated freeze-thaw cycles can all impact label performance. It’s essential to understand these factors to select the right labels and adhesives for cold storage applications.

Industries relying on cold storage prioritize accuracy, durability, and efficiency to ensure smooth operations in extreme conditions. Labels must align with these values, supporting seamless tracking, compliance, and product integrity. Each application brings unique demands that require tailored solutions to meet critical objectives.

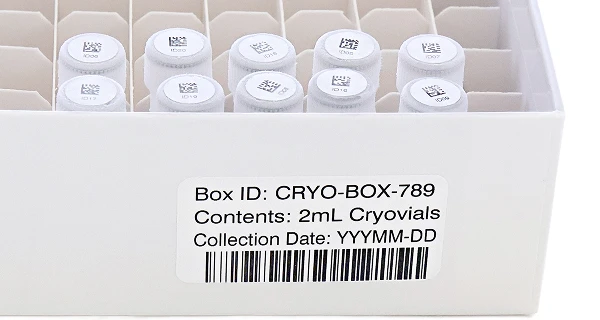

Biorepositories and cell therapy labs frequently use vapor or immersion storage in liquid nitrogen systems.

Labels must survive rapid freezing, chemical exposure, and years of storage without degradation or detachment.

Cryo-safe constructions offer permanent adhesion, chemical resistance, and image integrity at ultra-low temperatures.

Dry ice shipping is common in diagnostic logistics, lab transfers, and short-duration cryogenic handling workflows.

Labels exposed to dry ice must resist cracking, delamination, and fading during and after exposure.

Durable face stocks paired with cold-rated adhesives maintain adhesion and legibility throughout dry ice use.

Labels must flex with the container and resist adhesive fatigue through fluctuating cold and ambient temperatures.

Moisture buildup during each thaw cycle can disrupt adhesion or degrade the printed image.

Materials designed for elasticity, moisture resistance, and cold adhesion ensure labels remain secure.

Applying a label directly to a frosted surface introduces adhesion failure risks due to moisture barriers.

Typical adhesives bead or lift when frost is present, compromising identification from the start.

Adhesive systems engineered for frozen contact ensure a secure bond even without drying or warming first.

Routine storage in refrigerators, freezers, or cold rooms brings handling challenges like condensation and surface flex.

Moisture, variable dwell times, and frost-free cycles can all degrade adhesive strength or legibility.

Cold-compatible materials retain adhesion and print quality across typical lab and clinical storage environments.

See how cryo-ready labels perform in your workflow—request a sample to test durability, adhesion, and image clarity today.

Choosing the right label material for extreme cold storage is crucial to maintaining the integrity and traceability of your samples. Our specialized label materials are designed to perform reliably in the harshest conditions, from ultra-low temperature freezers to vapor and liquid nitrogen storage. Below, you’ll find a detailed overview of our top-performing materials, each tailored to specific cold storage environments to ensure optimal adhesion, durability, and readability.

Thermal transfer labels designed for cold storage stay compatible with matched printers and ribbons, ensuring adhesion and legibility across freezers, LN₂, and cryogenic applications.

Get fully or partially pre-printed pressure sensitive labels built to withstand freezing, condensation, and long-term storage—with durable print, precise sequences, and custom formatting.

Labware arrives labeled and ready for use—ideal for cryogenic storage. Pre-marked items offer excellent durability and can be prepared in cleanrooms or tare-weighed for added precision.

High-quality face stocks, cold-rated adhesives, and durable topcoats work together to ensure long-term integrity in cryogenic environments.

Label materials remain flexible in subzero conditions to prevent cracking, curling, or detachment during freezing, storage, and handling.

Select labels designed for seamless integration into print-and-apply automation systems operating in cold rooms or sterile lab environments.

We select face stocks like polyethylene, polypropylene, and polyester designed for flexibility and durability at sub-zero temperatures. Adhesive formulations include options that bond well to plastic and glass surfaces, even at -80°C. Each construction is chosen to resist brittleness, curling, and frost-related failure.

Cryogenic labels are exposed to dry ice, liquid nitrogen, and extended storage periods in ultra-low temperature freezers. We test label performance at -196°C and colder to ensure adhesion, readability, and flexibility over time. Validation includes print durability and adhesion on frozen or frosted surfaces when required.

Thermal transfer printing with cryo-compatible ribbons offers reliable in-lab printing for tubes, vials, and containers. We ensure material and ribbon combinations resist smudging or fading under cold, humid, or frosty conditions, and remain readable long after frozen storage.

Pre-printed labels for cold storage use durable inks and protective coatings to maintain legibility through freezing, thawing, and handling. Sequential data and matched sets are verified for accuracy and delivered in formats that support cold room workflows and automated tracking.

Sterilization-safe labeling doesn’t stop with the label itself—it’s about making sure your workflow, print process, and hardware all align. Our label solutions are compatible with a wide range of printing systems, including thermal transfer printers, laser printers, and fully automated label applicators. If you’re printing in-house, we’ll guide you toward face stocks and coatings that match your specific printer model, ribbon type, and print resolution needs.

In labs and cleanrooms where sterilization is required, hardware selection often impacts label durability. For instance, thermal transfer printing combined with resin ribbons offers enhanced chemical and heat resistance—critical for autoclave or chemical sterilant workflows. When automation is part of the process, we ensure label materials meet the physical requirements of robotic handling, high-speed printing, or tight label tolerances. No matter how you’re printing—whether it’s a single workstation or a full-scale automation line—our labels are designed to work with your equipment, not against it.

We convert labels in formats compatible with cryo vials, freezer boxes, and racks. This includes die-cut options for cap labels, wrap-around formats, and label sets that support easy handling with gloves or tweezers. Liners and finishes are chosen for smooth dispensing at low temperatures.

Cold storage labels aren’t off-the-shelf solutions—they’re purpose-built systems. Every label is engineered, tested, and converted to endure freezing, moisture, and cryogenic storage. From adhesive science to topcoat durability, each layer is selected for lasting performance in the most demanding cold environments. This is where cryo knowledge, material engineering, and converting precision come together.

Our labels are built to perform where others fail—from autoclaves to chemical exposure to cold-to-hot transitions and more.

We verify image clarity, adhesive performance, barcode readability, and sequencing to ensure consistent, high-performing results.

We help you choose the right face stock, adhesive, and finish based on your surfaces, sterilization method, and labeling goals.

Not all labels are built the same. Share a few details about your product or environment, and we’ll recommend a label designed to stick, stay readable, and hold up under pressure.

From deep freezers to cryogenic tanks, cold storage environments challenge every part of a label. These labels are engineered to stay adhered and clearly readable through freezing, condensation, and long-term storage. Whether applied by hand or automation, pre-printed or print-on-demand, they’re built for performance in demanding cold chain conditions.

Cold storage conditions challenge every layer of a label—from adhesive strength to print durability and material flexibility. Exposure to subzero temperatures, condensation, and long-term storage demands specialized construction to maintain adhesion and legibility. These solutions are built for reliability across a range of cold chain and cryogenic applications.

Used across labs and biobanks, these small-format containers require labels that survive freezing, immersion, and long-term cold storage.

Labeling for cryo boxes and storage racks must remain legible and adhered through handling, condensation, and deep-freeze conditions.

Extremely small and specialized, these containers need labels that endure LN₂ exposure without cracking, curling, or losing adhesion.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields