Thermal transfer barcode label printers offer efficient, high-quality on demand printing for clear identification and tracking. From small desktop models to robust industrial printers, these solutions provide flexibility and durability across various environments. Thermal transfer options ensure long-lasting labels that withstand challenging conditions.

Thermal transfer printers are ideal for creating durable, high-quality labels that last. They use a heated ribbon to transfer ink onto the label material, resulting in crisp, long-lasting prints resistant to smudging and fading. This printing method is highly versatile, supporting a wide range of materials like polyester, polypropylene, and vinyl for specialized labeling needs.

Thermal transfer printers excel in environments where labels are exposed to extreme temperatures, chemicals, or heavy handling. Their ability to print high-density barcodes and detailed graphics makes them perfect for asset tracking, compliance labeling, and inventory management. Additionally, they offer low maintenance costs and reliable performance for high-volume printing tasks.

Thermal transfer printers offer a range of specialized features designed to meet complex labeling requirements in various industries. These printers provide enhanced capabilities that improve efficiency, accuracy, and adaptability, making them an ideal choice for businesses with diverse labeling needs.

Desktop thermal transfer printers are compact solutions designed for small to medium-sized labeling tasks. They offer a user-friendly experience while maintaining the reliability and print quality needed for various applications. These printers are ideal for environments with limited space or where portability is essential.

Desktop thermal transfer printers are best suited for businesses that require consistent, high-quality labeling in a compact form. These printers excel in offices, labs, and retail spaces where efficiency and flexibility are key. Meeting specific needs helps ensure optimal performance and reliability in these environments.

The Zebra ZD Series offers a versatile range of compact desktop printers designed for reliable, high-quality labeling. Ideal for applications in healthcare, retail, and small-scale manufacturing, the ZD Series supports quick, consistent barcode label production with advanced connectivity options and intuitive interfaces.

The TSC TC Series is a line of durable and economical printers that balance cost-efficiency with dependable performance. Known for their robust design and media support, these printers are perfect for asset tracking, inventory management, and light industrial labeling. The TC Series provides versatile solutions for small to medium operations.

The cab EOS Series combines advanced features with a compact, user-friendly design. These printers offer flexible media options and intuitive touchscreens, making them suitable for a wide range of labeling tasks in office, lab, and light industrial settings. The EOS Series delivers precise, high-resolution printing for clear, reliable labels.

Industrial thermal transfer printers are built to handle high-volume, heavy-duty labeling needs. These printers are designed for demanding environments, providing robust construction, speed, and reliability. Ideal for manufacturing, warehousing, and logistics, industrial printers ensure consistent and durable labels under challenging conditions.

Industrial thermal transfer printers excel in environments where durability and efficiency are critical. These printers are designed for continuous operation and high-volume tasks, delivering reliable performance in harsh settings. Understanding their key requirements helps businesses choose the right solution.

The cab MACH 4S is a compact yet powerful industrial printer designed for applications requiring precise and detailed labels. It features an easy-to-use interface and versatile media handling, making it suitable for manufacturing, laboratory, and light industrial environments. The MACH 4S balances performance and flexibility.

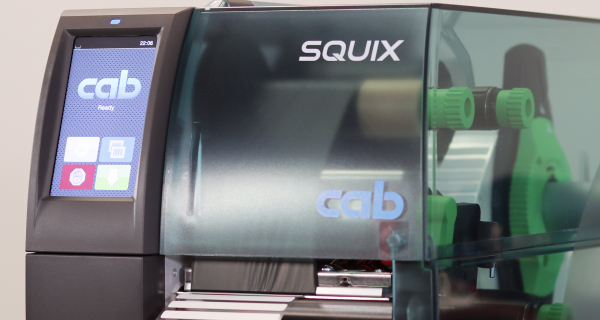

The cab SQUIX series offers precision and reliability for complex industrial labeling tasks. With a modular design and a variety of accessories, including applicator attachments, these printers provide flexible solutions for diverse labeling needs. Built to handle tough conditions, the SQUIX series combines efficiency with robust construction.

The Zebra ZT Series delivers versatile, high-performance printing solutions designed for demanding industrial environments. Known for their durability and advanced features, these printers support high-resolution printing and a wide range of connectivity options. The ZT Series is ideal for high-volume industrial applications.

Thermal transfer printers are essential for creating durable, high-quality labels in various industries. They offer flexibility, advanced features, and reliable performance, making them the preferred choice for applications that require long-lasting and clear labeling. Understanding the specific components and capabilities of these printers helps businesses make informed decisions to meet their labeling needs.

Thermal transfer printers are designed to create durable, high-quality labels across a wide range of applications. These printers consistently produce clear, long-lasting prints that withstand harsh conditions. Their defining features ensure reliable performance and adaptability in various industries.

Thermal transfer ribbons come in three main types—wax, wax/resin, and resin—each designed for different applications and levels of durability. Wax ribbons are cost-effective and ideal for standard paper labels, offering a good balance of print quality and affordability. Wax/resin ribbons are more versatile, providing better resistance to smudging, scratching, and moderate chemical exposure.

Resin ribbons are the most durable, designed for high-performance applications where labels face extreme conditions like chemicals, heat, or abrasion. Custom ribbons can be formulated to enhance durability and printability, offering advanced protection against harsh environments. Additionally, color options such as single-color and dual-color ribbons allow for greater flexibility in label design.

The relationship between the label materials and the printer is crucial for achieving consistent, high-quality results. Issues often arise not from the printer itself, but from using labels that aren’t compatible with the printer’s heat settings or ribbon type. The face stock must be selected to work seamlessly with the printer, ensuring that it can absorb and bond with the transferred ink without smudging or fading.

Similarly, adhesives should be chosen to withstand the printer’s thermal process and remain securely attached to the intended surface. When label materials aren’t properly matched to the printer’s capabilities, it can lead to poor print quality, reduced durability, and operational inefficiencies. Properly aligning the face stock and adhesive with the printer’s specifications is key to avoiding these problems.

Looking for the right printer for your labeling needs? Fill out the form below, and our team will guide you to the best solution for your application.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields