Barcodes are the foundation of reliable identification and traceability across industries. From laboratories to logistics, precise labeling ensures data integrity, regulatory compliance, and seamless automation.

Whether pre-printed or printed in-house, barcode labels connect physical assets to digital systems with unmatched efficiency.

Barcodes transform physical objects into digital records, enabling instant identification and seamless data capture. By connecting labels with systems, organizations achieve greater accuracy, speed, and visibility. From managing assets to tracing products across global supply chains, barcode labels are the starting point for smarter operations.

Barcode labels uniquely identify assets, enabling efficient monitoring, auditing, and lifecycle management. With accurate tracking, organizations reduce losses, optimize utilization, and maintain full accountability across diverse environments.

By linking products and packaging through standardized barcodes, businesses gain real-time insight into movement, handling, and storage. Visibility across global operations strengthens compliance, reduces errors, and improves decision-making.

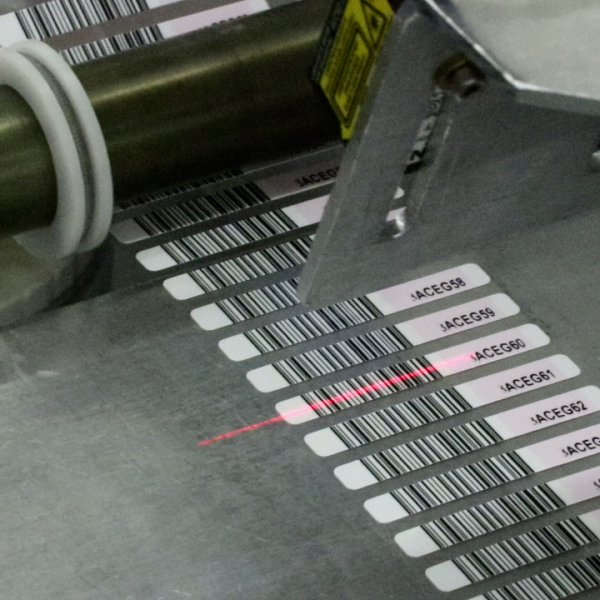

Barcode scanning eliminates manual data entry, accelerating processes and improving accuracy. Faster, error-free data capture enhances productivity, compliance, and the ability to scale efficiently across industries.

Encodes 106 distinct characters using three interchangeable code sets for optimal density and flexibility. Provides compact linear symbols, making it ideal for logistics, healthcare, and regulated indSupports GS1 Application Identifiers, enabling standardized supply chain communication and regulated compliance worldwide.ustry identifiers.

Encodes data in black and white modules arranged in square or rectangular patterns with high density. Uses Reed–Solomon error correction, allowing accurate decoding despite surface damage, fading, or distortion. Dominates in healthcare, electronics, and industrial parts marking where space and durability are critical.

Encodes numeric, alphanumeric, and binary data with flexible symbol sizes and four correction levels. Error correction restores data even with up to thirty percent of the symbol damaged or obscured. Widely used for consumer interaction, but equally effective in secure, industrial, or research labeling.

Encodes digits by interleaving bars of one digit with spaces of another, doubling data density. Requires generous quiet zones and bearer bars, ensuring reliable scanning on corrugated or uneven surfaces. Commonly used as ITF-14 for shipping cases, supporting global distribution and supply chain labeling.

Composed of multiple stacked rows of linear codewords, enabling storage of thousands of characters per symbol. Incorporates error correction levels zero through eight, balancing capacity with readability after partial damage.Used in transport documents, identification cards, and industrial labeling requiring high information density.

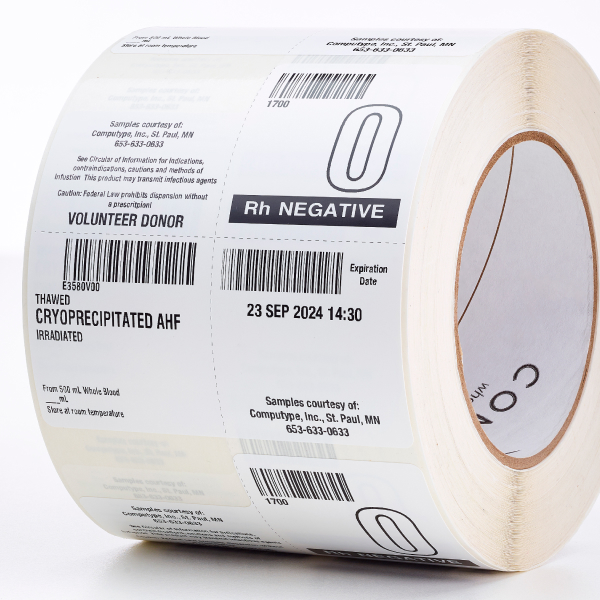

ISBT 128 encodes blood, tissue, and cellular products using standardized data structures on Code 128. GS1 DataBar provides compact linear symbols for small healthcare items and unit-dose pharmaceutical packaging. MaxiCode and Pharmacode support parcel logistics and pharmaceutical production line error detection respectively.

Linear barcodes are simple and widely adopted, while 2D symbologies offer higher data capacity, error correction, and durability on limited surface areas.

High-density barcodes conserve space but require precise printing and scanning. Lower-density formats improve reliability when printing or scanning conditions are less controlled.

Selecting the right code depends on regulatory demands, available print space, scanning environments, and data requirements across laboratory, industrial, or logistics workflows.

Not all labels are built the same. Share a few details about your product or environment, and we’ll recommend a label designed to stick, stay readable, and hold up under pressure.

Barcodes transform physical objects into digital records, enabling instant identification and seamless data capture. By connecting labels with systems, organizations achieve greater accuracy, speed, and visibility. From managing assets to tracing products across global supply chains, barcode labels are the starting point for smarter operations.

Designing barcodes in-house with software like BarTender or NiceLabel offers flexibility and control. You can manage data sources, serialization, and layouts yourself, but it requires training, maintenance, and process discipline to avoid costly design or compliance errors.

Suppliers can design and pre-print barcodes that are guaranteed to meet regulatory and quality standards. This reduces in-house burden and ensures consistency, but sacrifices flexibility for on-demand adjustments and often requires ordering in advance to maintain inventory.

Enterprise systems can embed barcode generation directly into lab or production workflows. This ensures seamless data consistency and automation, but design flexibility is limited to what the system supports, and implementation requires upfront investment in configuration and integration.

BarTender supports every major symbology, from linear to complex 2D codes, ensuring flexibility across industries and compliance with GS1 and UDI requirements.

It integrates with ERP, WMS, and LIMS platforms, automating serialization, variable data printing, and approval workflows without manual intervention.

Advanced features include secure user roles, electronic signatures, and audit trails, making it ideal for regulated environments in healthcare, pharma, and electronics manufacturing.

Loftware NiceLabel offers centralized control, eliminating label duplication across sites and ensuring version consistency through secure templates and global access.

Its cloud architecture supports remote printing, supplier labeling, and direct integration with SAP, Oracle, and other enterprise systems at scale.

The system enhances compliance by enforcing GS1 formatting, serialization rules, and ISO print-quality standards, while reducing IT burden through standardized templates and automation.

Precise design standards guarantee first-pass scan success, reducing bottlenecks and preventing costly identification errors across laboratory, industrial, and logistics workflows.

Barcode design directly affects regulatory acceptance in industries like healthcare, electronics, and automotive, where errors can compromise safety, traceability, or audit compliance.

Design choices influence readability after exposure to chemicals, abrasion, cryogenic temperatures, or heat, ensuring barcodes remain functional throughout product lifespans.

The X-dimension, or module size, defines the width of the narrowest element in a barcode. It sets the foundation for overall symbol size, density, and readability. Printers must generate modules with consistent width, since even small variations distort the encoded data. Different symbologies specify allowable X-dimensions, often expressed in mils (1/1000 of an inch). For example, Code 128 may require modules of 7.5–20 mils depending on application. High-density codes like Data Matrix and QR can shrink modules further, but doing so increases demand on printer resolution and scanner optics. Matching X-dimension to printer resolution is critical. A 203 dpi printer struggles with modules under 10 mils, while a 600 dpi printer reliably produces much smaller sizes. Selecting the correct X-dimension ensures the barcode balances available label space with reliable scanning, especially in harsh environments where dirt, frost, or abrasion already threaten readability.

Quiet zones are mandatory blank spaces surrounding a barcode, ensuring scanners detect the start and end of data. Without sufficient margins, readers may misinterpret surrounding graphics, text, or packaging elements as part of the code. ISO and ANSI standards define minimum quiet zones, typically four times the X-dimension for linear barcodes. Two-dimensional codes like Data Matrix or QR require clear boundaries on all sides, often set by fixed finder patterns. Inadequate quiet zones reduce scanning efficiency, causing retries or failures in automated workflows. For regulated industries, this can delay processing, compromise compliance, or trigger relabeling. Effective design accounts for available space, ensuring quiet zones remain unobstructed even after die-cutting, label application, or environmental wear. Maintaining proper margins ensures barcodes remain machine-readable in both handheld and high-speed automated systems, protecting data integrity from creation through end-of-life.

Barcode scanners rely on reflectance differences between dark and light elements. Print contrast, measured as Print Contrast Signal (PCS), quantifies this ratio. ISO/IEC standards typically require PCS values above 0.7 for reliable performance, though tolerance varies by scanner technology. Low-contrast printing arises from faded ink, glossy substrates, or inadequate ribbons. Reflective materials, such as shiny metals or plastics, can cause scanners to misread bars due to glare. Similarly, low-temperature or chemical environments may degrade contrast over time. Design and material selection must consider both immediate legibility and long-term durability. Using thermal transfer printing with resin ribbons on matte, coated labels often achieves superior PCS. Protective topcoats or laminates preserve contrast against solvents and abrasion. Maintaining contrast within specification ensures barcodes remain scannable across workflows, whether in frozen storage, production lines, or field logistics.

Check digits add mathematical verification to barcode data. In linear symbologies like EAN-13 and Code 128, algorithms calculate a trailing check character from the encoded string. Scanners recalculate this digit upon reading; mismatches indicate errors caused by damage, distortion, or operator miskeying. This simple redundancy is vital for regulated environments where data accuracy underpins patient safety, compliance, or traceability. For example, mistyped blood bag identifiers could cause catastrophic mismatches if not caught. Beyond single check digits, advanced error detection structures exist. ISBT 128 and GS1 systems incorporate structured identifiers with embedded checksums, further reducing risk. While check digits slightly increase data length, the reliability they provide outweighs efficiency concerns. Incorporating check digits wherever supported ensures barcodes maintain data integrity, preventing silent failures that could otherwise propagate through laboratory, clinical, or supply chain systems.

Unlike linear barcodes, most 2D symbologies include error correction using Reed–Solomon or similar algorithms. Data Matrix and QR Codes can reconstruct lost information even if symbols are partially obscured, torn, or dirty. Error correction levels define redundancy — QR Codes, for example, offer L (7%), M (15%), Q (25%), and H (30%) recovery. Higher levels increase resilience but reduce net data capacity, demanding careful balance between robustness and efficiency. In harsh conditions like cryogenic storage or chemical exposure, elevated error correction improves survival rates, especially when frost, solvents, or abrasion compromise image clarity. Verification tools confirm whether printed codes meet error correction specifications, providing assurance for regulatory audits. Effective design leverages appropriate error correction levels for the application: minimal redundancy for retail packaging, maximum redundancy for life sciences or aerospace. Correctly implemented, error correction safeguards continuity of traceability even when environments threaten barcode survival.

Barcode orientation and placement directly influence readability, especially in automated scanning environments. In linear codes, “picket fence” orientation (bars perpendicular to the feed direction) reduces print distortion compared to “ladder” orientation (bars parallel to the feed). However, curved surfaces such as vials or tubes may demand ladder orientation to prevent bar compression. Placement must consider available quiet zones, surface curvature, and scanner line of sight. For 2D codes, flat placement is critical, as warping distorts finder patterns required for alignment. In high-throughput labs or warehouses, misplacement can reduce first-pass read rates, slowing operations. Harsh environments further complicate placement — solvents may erode exposed areas, or frost may accumulate unevenly. Designing with placement in mind ensures barcodes perform consistently, whether applied to microcentrifuge tubes, tire sidewalls, or electronic components. Proper orientation and positioning reduce scanning errors, protect compliance, and sustain workflow efficiency.

Barcode performance depends not only on design but also on survival in application environments. Labels in cryogenic storage, sterilization cycles, or high-heat manufacturing face chemical, thermal, and physical stressors. Barcodes may blur, delaminate, or lose contrast if materials and printing methods are not properly matched. Environmental durability testing evaluates resistance to solvents like xylene or isopropanol, temperature extremes from –196°C to 450°F, and abrasion from handling or equipment. Linear codes are more vulnerable to surface damage because missing bars cause unreadability; 2D codes with error correction often withstand partial damage. Selecting durable substrates, such as polyester or polypropylene, and using resin thermal transfer ribbons improves resilience. Protective laminates or specialty coatings extend life under extreme stress. Designing barcodes for environmental durability ensures that traceability persists throughout laboratory procedures, industrial production, or logistics supply chains, meeting compliance standards and operational requirements.

Barcode design is a balance of precision and pragmatism. Quiet zones, contrast ratios, and X-dimensions all affect scannability — especially when space is tight or the label will face wear, frost, or chemical exposure.

Deciding whether to print barcode labels in-house or source them pre-printed from a professional supplier impacts cost, flexibility, and reliability. The right choice depends on label volume, environmental conditions, compliance requirements, and integration with existing systems. Each option offers unique benefits and trade-offs.

On-demand printing enables laboratories and manufacturers to create barcodes as needed, ensuring flexibility and fast turnaround. However, it requires investment in printers, ribbons, media, and trained staff to maintain consistent print quality across all labels.

Professional suppliers produce barcodes with high-grade durability, advanced materials, and exact compliance with industry standards. While less flexible, pre-printed solutions excel in consistency, large-volume efficiency, and performance in demanding environments like cryogenic storage or high-heat manufacturing.

A blended strategy combines the strengths of both methods: base labels are pre-printed with fixed information, while variable data is applied in-house. This approach balances professional durability with responsive, flexible updates for serialization, expiration dates, or lot tracking.

High-density barcodes like Data Matrix or QR often demand 300–600 dpi printing for accurate scanning. Lower-resolution printers may suffice for linear barcodes, but risk readability issues when encoding dense data or small labels.

Durability depends on method: resin ribbons for chemical resistance, UV-cured inks for permanence, or protective laminates that guard barcodes without distorting scanners’ line of sight. Correct selection prevents costly relabeling.

Paper, polyester, and polypropylene all behave differently with thermal, digital, or flexographic printing. Selecting label stock that matches both print method and environment ensures reliable adhesion and image permanence across applications.

Barcode quality isn’t just about whether a scanner can read it once — it’s about ensuring every code performs consistently in real-world use. Verification and validation processes guarantee compliance with ISO/IEC standards, while advanced grading ensures barcodes meet the demands of regulated industries. True value comes when these steps are paired with reliable sequence management.

Duplicate identifiers undermine trust, disrupt operations, and can cause compliance failures. Collision prevention uses centralized serialization logic, controlled allocation, and inline verification to guarantee that no two barcodes are ever repeated—even across massive volumes and multi-year production runs.

Effective sequence management keeps identifiers in precise order without gaps, drift, or re-use. This discipline ensures continuity for sample tracking, production lots, and serialized assets, where misordered or skipped barcodes can cause costly errors or failed audits.

Industries like healthcare, pharmaceuticals, and regulated manufacturing require documented proof that every identifier is unique and accounted for. Professional-grade printing adds inspection reports and traceability logs, ensuring organizations can demonstrate compliance and protect against regulatory or quality-control challenges.

Each barcode must be globally unique and non-repeating. Strong serialization logic, locked templates, and centralized range allocation eliminate risk of duplicate identifiers.

Professional-grade printing systems verify every label, maintain sequence integrity across runs, and prevent numbering drift — even in high-volume production environments.

Industries like healthcare, blood banking, and pharma require documented proof of uniqueness. Audit trails and reporting demonstrate no collisions across millions of printed labels.

Verification measures printed symbol quality against defined parameters to ensure consistent decodability across devices and environments. Using a compliant verifier, you capture attributes such as Symbol Contrast, Modulation, Edge Contrast, Defects, Decodability, and Quiet Zone (for 1D) or their 2D counterparts. Unlike a quick “can it scan?” check, verification standardizes illumination, aperture, sampling, and decode algorithms to remove reader bias. You grade results per the applicable standard, document pass/fail thresholds, and link corrective actions to specific root causes (print darkness, speed, ribbon/substrate mismatch, BWR, laminate glare). Effective programs define sampling plans (incoming, in-process, final), specify minimum grades by use case, and re-verify after environmental conditioning (cryo, heat, solvents, abrasion) to confirm lifecycle performance.

Validation confirms the content, carrier, and format meet system and regulatory requirements. You verify that the chosen symbology (e.g., GS1-128, Data Matrix) matches specifications, that data structures comply (GS1 Application Identifiers, UDI device/production identifiers, ISBT 128 structures), and that Human-Readable Interpretation and label layout meet rules. Validation also checks field lengths, character sets, check-digit algorithms, date/lot formats, and serialization logic against master data and downstream systems (LIMS/ERP/WMS). Implementers enforce schema-level rules at label generation, perform round-trip tests (encode → decode → parse), and simulate edge cases (leading zeros, variable-length AIs, transposition). Validation prevents “correctly printed, operationally useless” barcodes by ensuring each scan resolves to the right data in the right workflow.

Grading assigns a quantitative quality score to each symbol. Historically, ANSI X3.182 introduced A–F letter grades for linear codes; that standard is now withdrawn. Modern verifiers implement ISO/IEC grading with numeric scores (4.0–0.0) that map to letters for continuity (A≈4.0, B≈3.0, etc.). The overall grade equals the lowest graded parameter, emphasizing weakest-link control. Programs set minimum acceptable grades by application—e.g., higher for automated conveyor scanning than for local bench scanning. Engineers trend grades over time to detect drift (printhead wear, ribbon lot changes, substrate switches), correlate failures to process variables, and lock settings once capable. Grading makes quality visible, comparable, and auditable across plants, suppliers, and customers.

ISO/IEC 15416 defines how to measure and grade linear (1D) barcodes such as Code 128, ITF-14, and EAN/UPC under controlled conditions. It specifies illumination (typically red ~660 nm), aperture sizes, sampling, and calculation of parameters including Symbol Contrast, Minimum Reflectance, Edge Contrast Minimum, Modulation, Defects, Decodability, and Quiet Zone. Each parameter receives a grade; the symbol’s overall grade is the lowest of those values. Implementers must set appropriate aperture/scan path for X-dimension, avoid truncated heights, control bar growth with Bar-Width Reduction (BWR), and manage substrate glare (matte finishes, non-specular laminates). 15416 compliance ensures a label that decodes on any conformant scanner—not just the one on your bench—and travels reliably through mixed supply chains.

ISO/IEC 15415 governs print quality for 2D symbols (Data Matrix, QR Code, PDF417, etc.). It defines illumination/geometry and grades parameters tailored to matrix/stacked codes: Contrast, Modulation, Axial Non-Uniformity (X/Y scaling imbalance), Grid Non-Uniformity, Fixed-Pattern Damage (finder/clocking/timing patterns), Unused Error Correction (UEC), and Decodability. Because 2D symbols embed error correction, 15415 quantifies how much redundancy decoding consumes (UEC)—a sensitive indicator of marginal print or surface effects. Robust 2D design manages module size relative to DPI, avoids warping on curves, preserves quiet zones on all sides, and prevents optical distortion from varnishes/laminates. Meeting 15415 is essential for tiny labels (tubes, slides, components) and hostile environments where partial damage is expected.

The GS1 General Specifications define data structures (Application Identifiers), permitted carriers (EAN/UPC, ITF-14, GS1-128, GS1 DataMatrix, GS1 QR), HRI rules, and carrier-specific size/placement requirements (X-dimension ranges, magnification, bearer bars for ITF-14, quiet zones, symbol heights). They also standardize check-digit algorithms (Mod-10) and date/lot encodings, enabling interoperability from manufacturing to retail and healthcare. Implementers map business data (GTIN, lot, expiry, serial, SSCC, GIAI/GRAI) to AIs, select an appropriate carrier per packaging level, and validate that printed symbols meet both GS1 carrier rules and ISO print-quality grades. The Specs unify what you encode and how you present it so trading partners and regulators decode consistently.

Beyond basic identification, barcodes now secure products, verify authenticity, and manage serialized data across supply chains. These functions prevent counterfeiting, improve traceability, and support compliance with regulations in pharmaceuticals, medical devices, and industrial manufacturing. Each adds unique value while strengthening end-to-end visibility and trust.

Security features enhance barcodes with encrypted data, covert markers, or tamper-evident labels. These tools deter counterfeiting, safeguard high-value products, and ensure that codes cannot be easily duplicated. Secure barcodes are increasingly critical in pharmaceuticals, medical devices, and automotive parts where consumer safety and brand integrity are at stake.

Authentication confirms a product’s legitimacy by linking the barcode to a trusted database or blockchain record. Scanning verifies whether the item originated from an authorized source, giving regulators, businesses, and customers confidence. Industries with strict quality and safety standards, like blood banks or electronics, rely on these mechanisms daily.

Serialization assigns a unique barcode to each individual unit, enabling item-level traceability. This prevents duplication, improves recalls, and supports compliance with regulations like DSCSA in pharma or UDI in healthcare. Serialization enables granular tracking throughout global supply chains, from manufacturing to distribution and patient or customer use.

Secure barcodes and authentication systems protect patients, customers, and brands. They deter counterfeiters while ensuring only legitimate products move through regulated supply chains.

Serialization ensures adherence to pharmaceutical DSCSA, medical device UDI, and automotive standards. It streamlines audits and reduces costly rework during recalls or inspections.

Unit-level barcodes deliver end-to-end visibility. Manufacturers, distributors, and customers can track every item’s journey, enabling stronger quality control and operational efficiency.

Modern barcodes support advanced functions that extend reliability, adaptability, and efficiency. These features enhance accuracy, protect sensitive information, and maintain readability even under demanding conditions or in regulated workflows.

Structured formatting, prefixes, and suffixes enable seamless integration with databases and enterprise systems, eliminating manual data entry and streamlining operations.

Concatenation links multiple data fields together in one scan

Error correction recovers information from damaged labels

Encryption protects sensitive or regulated information

Anti-counterfeit features verify label authenticity

These features are especially vital in regulated industries, high-throughput environments, and applications requiring precise traceability. Some are encoded within the barcode itself, while others are configured through printing, scanning, or software systems. Leveraging them strategically builds a barcode program that is accurate, secure, and scalable.

Barcodes enable critical functions in nearly every industry, from global logistics to regulated healthcare. Each sector has unique requirements for symbology, durability, compliance, and serialization. Tailoring label design and printing strategies to these needs ensures accuracy, compliance, and operational efficiency across diverse environments and workflows.

ISBT 128 defines uniform identifiers, data structures, and label formats for blood, tissues, and cellular therapies. It ensures consistent traceability across collection, processing, storage, and transfusion, regardless of country or software platform. Compliance is mandatory for accredited blood banks and transplant centers worldwide, reducing errors and improving safety.

GS1 UDI assigns device identifiers (DI) and production identifiers (PI) for each medical device label. It supports global harmonization by aligning with FDA, EU MDR, and other regional requirements for device tracking. Hospitals, regulators, and patients benefit from improved recalls, reduced errors, and enhanced supply chain transparency.

DSCSA requires manufacturers and repackagers to mark packages with a unique serialized GS1 DataMatrix. Serialized barcodes encode GTIN, serial number, lot, and expiration, enabling unit-level tracking through the supply chain. This protects patients by preventing counterfeit drugs, simplifying recalls, and ensuring visibility from manufacturer to dispenser.

AIAG guidelines specify label formats, data identifiers, and required symbologies like Code 128 and Data Matrix. They unify suppliers and OEMs by creating consistency in parts labeling, shipping labels, and transport documents. Compliance reduces errors, enables automation, and ensures interoperability across complex, multi-tier automotive manufacturing networks.

Libraries use Codabar and ISIL identifiers to manage loans, track items, and support shared catalog systems. These simple linear codes are cost-effective, easy to implement, and supported by legacy infrastructure worldwide. Even with digital catalogs, barcodes remain the most efficient and durable tool for item-level tracking.

MIL-STD-129 governs external packaging labels for shipments, including pallet, carton, and container identification. MIL-STD-130 requires permanent marking of parts and equipment with serialized 2D Data Matrix codes. These standards ensure asset traceability, lifecycle management, and interoperability across defense, aerospace, and military supply chains.

Regulatory standards demand specific barcode symbologies. Compliance avoids penalties, ensures traceability, and guarantees acceptance across international supply chains and healthcare systems.

Barcode performance depends on durability. Harsh conditions like cryogenic storage, autoclaves, or industrial curing require specialized label materials and tested symbologies.

From biobanking to electronics assembly, workflows often involve automation and multi-step validation. Industry-tailored barcodes ensure smooth integration, accuracy, and repeatability.

With over 50 years of experience designing and producing barcode labeling solutions, our engineers have solved nearly every challenge imaginable. From data structure and symbology selection to print durability and scanning performance, we’ve seen it all—and we’re sharing the insights that help ensure every barcode you print performs flawlessly.

Generating and printing barcode labels starts with defining the data and barcode type you need. Use barcode labeling software to create templates, assign data fields, and generate barcodes automatically from your database or spreadsheet. Thermal transfer printers are the most common choice because they offer sharp, durable print quality on label materials suited for different environments. Match your label size and resolution to the barcode density so symbols are easily scannable. Before mass printing, verify the barcode using a verifier to confirm it meets ISO/IEC standards for contrast and readability. Always test printed labels under real scanning conditions, as lighting, curvature, or material finish can affect scan performance.

Barcode labeling software should match how your data is managed and how your labels are printed. For most organizations, the key factors are database connectivity, template flexibility, and printer compatibility. Software like BarTender or Loftware integrates directly with systems such as LIMS, ERP, or warehouse management software to automate data flow and prevent errors. Look for tools that support your required barcode symbologies, GS1 formatting, and variable data printing. Features like user access control, version tracking, and serialization management are important for regulated environments. A good solution simplifies label creation and reduces manual steps, ensuring consistent and compliant output across all printers and production sites.

Selecting a barcode symbology depends on how much data you need to encode, how the barcode will be scanned, and any standards you must follow. Linear (1D) barcodes such as Code 128 or ITF-14 are ideal for short identifiers and fast, long-distance scanning. Two-dimensional (2D) barcodes like Data Matrix, QR, or PDF417 hold much more data in less space and include error correction for damaged or curved surfaces. Many industries, including healthcare and logistics, follow GS1 standards, which dictate the specific symbology and data structure to use. When space is limited or labeling curved items like vials or PCBs, 2D barcodes are often the best choice. Always confirm symbology requirements with your trading partners or regulatory body before implementation.

Barcode density increases as modules or bars get smaller, allowing more data to fit into a smaller area. However, higher density also reduces scanning tolerance—especially under motion, distance, or low contrast. Compact barcodes require higher print resolution and precise registration to maintain edge clarity. Larger bar or module sizes make scanning easier and more forgiving, particularly when labels are curved or read by fixed-position scanners. In most cases, it’s better to balance data capacity with real-world scan distance and label durability rather than pursuing maximum density. Verify the barcode under the same lighting, angle, and motion speed expected in use to ensure consistent first-pass read rates.

Different printing technologies produce different results for barcode accuracy and durability. Thermal transfer printing offers the best consistency and sharpness for high-contrast, long-lasting barcodes. Direct thermal printing is convenient but fades over time, making it unsuitable for long-term use or heat exposure. Inkjet and laser printing can achieve high resolution, but ink spread, substrate absorption, or glare may reduce readability. Flexographic printing is excellent for large production runs but requires precise plate control to maintain narrow bars. For harsh environments, use a durable face stock and a compatible resin ribbon or protective laminate. Always test print samples for optical clarity and resistance to chemicals, abrasion, and temperature before full production.

Many barcode failures stem from small encoding or formatting errors. Common issues include using the wrong character set (for example, switching Code 128 subsets incorrectly), omitting check digits, or misplacing FNC1 characters in GS1 symbols. Variable-length fields without proper separators often make barcodes unreadable, and dropping leading zeros can change meaning entirely. Another frequent problem is truncating symbol height or compressing bar widths below minimum X-dimension. Always validate data strings before printing using a rules-based verifier or software validator. Then, test live labels with the same scanners used in your workflow. This ensures that each barcode decodes correctly under real-world conditions and prevents costly relabeling.

Yes. 2D barcodes like Data Matrix and QR can carry encrypted or digitally signed data, allowing them to act as secure identifiers. They can include authentication tokens, public-key signatures, or serialized URLs linked to secure verification servers. In anti-counterfeiting applications, each code is unique and verified against a controlled database. Error correction also helps preserve data integrity even when a label is partially damaged. For the best results, pair secure codes with durable label materials and printing methods resistant to tampering or chemical removal. Remember that barcode security relies as much on how the data is managed and verified as on the printed symbol itself.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields