Due to the complexities and customizations required to realize the maximum return on an RFID solution, it’s important to view implementation as a step-by-step process rather than a one-off event.

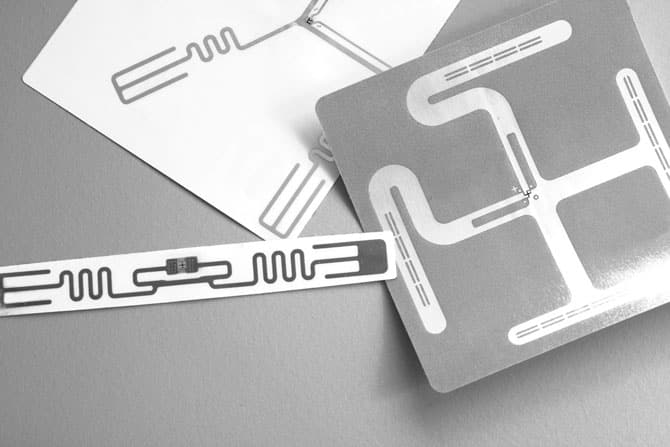

RFID integration involves a lot more than just adding inlays to labels, you will need readers to interrogate the labels, and software to translate and encode the stored information. You’ll also need to be sure to choose the right type of label structure and RFID technology to withstand your practices and environment.

With so much going into building an RFID strategy and the corresponding infrastructure, implementing RFID tends to be a much larger investment than a barcode strategy. Anytime you’re making a big investment you want to ensure it will meet your needs and expectations. In order to do so with RFID you need to allow enough time to follow each of the most critical steps to your implementation success.

We’ve broken down the RFID implementation process into the following eight steps that we feel are most critical to the success of any RFID implementation plan to help you better gauge the importance of each step to the success of your final RFID solution. This process will take time, but it’s time well spent when your final RFID system is tailored to meet your specific needs.

1. Review

The review stage requires those team members who are most familiar with the current state of the processes you want to improve with RFID. This group generally includes operations, subject matter experts, and anyone else who will be impacted by modified workflows. Your integration partner should also be included in this part of the process since their familiarity with RFID technology will help them identify roadblocks and opportunities for improvement where your team might not be able to.

The main focus of this stage is data collection and operational intelligence. It’s during this stage that important environmental hurdles and expected interference materials are documented. By documenting this type of information your RFID integration partner can help you find solutions to interference related issues.

2. Analysis

Analysis is the stage in which the data collected from the review phase is broken down and the highest priority projects are identified. Depending on the application, the priorities may be defined very differently.

For example, in an application where the most important factor is innovation rather than operational efficiencies, the priority may be a solution that provides a platform for innovative features as opposed to workflow/automation improvement. In an environment where data security is critical, the ability to encrypt stored and transmitted data may be the top priority.

The analysis team will generally be comprised of those with a vision of the ideal future state. This may involve operations, product managers, or marketing depending on the application and priorities.

3. Scoping

The Scoping stage is generally the third stage of the implementation process. During this stage the collected data is further reviewed and segmented to prepare for design.

A rough timeline is created at this point focusing primarily on the priority items and making room for additional steps that may have been identified during further review. It is also during this phase where the question should be answered “What defines success?” Being able to place parameters and measurements around this simple question is critical to the implementation of an RFID solution as your RFID solution may be subject to change during the testing and piloting phases.

4. Design

At this stage, the initial solution is designed to accommodate the needs recognized during all previous stages. Depending on your needs, the solution may include hardware, software, and services alongside the consumable RFID labels.

Also during the design phase, the test plan is generated based on the unique challenges your facility faces and shared with the stakeholders.

5. Testing

Testing involves methodically walking through the application of the design. Within testing, it is important to isolate the variables of the overall system (such as printing, environmental material exposure, antenna range, etc.) essentially mimicking the real world application. Once the individual parts of the solution pass initial testing, the solution can then be put together to perform end-to-end testing.

6. Pilot

After initial testing is completed, running a pilot allows for system modification before rolling out the final solution. The pilot program requires running end-to-end in the same manner the solution will be used in the real world, but with a subset of jobs or processes to provide feedback and ensure the solution is ready for implementation.

If issues are noted during the pilot process the solution may jump back to the design step for some fine tuning. If the pilot looks great on the first run, then you and your integration partner can move right on to the next step.

7. Implementation

Implementation is the full launch of the RFID solution. It is at this point, the solution should have passed all requirements and qualifications in both the initial testing phase and the pilot program.

This step not only includes the physical implementation of the solution, but also employee training. This step can take time, especially as employees grow used to their new workflow.

8. Retrospective

An important, but often overlooked step in any RFID solution project is a retrospective. It is critical to take the data procured during the process and review it to determine if the project suffered scope creep, review the hurdles encountered during the process, and measure the overall success of the project.

Like any other large investment, you want to be sure you will see a return on your RFID investment. Although there is no single trick to ensure your implementation will go completely as planned you can reduce risk when you take the time to search for the right partner, invest in the right tools to build your infrastructure and walk through each step in the RFID implementation process.

Working with a partner who will visit your site to review and analyze your processes and environment then build, test and pilot a design tailored to your needs will ensure your RFID solution is built to withstand your unique conditions. Once you begin implementing your solution you should take time to reflect on how well the system is working with your processes, infrastructure and employees.

Walking through each step in this process allows you to reduce the risk involved in your investment, plan for the future and continuously improve your processes.

Connect with our labelling experts today

Blog article form

"*" indicates required fields