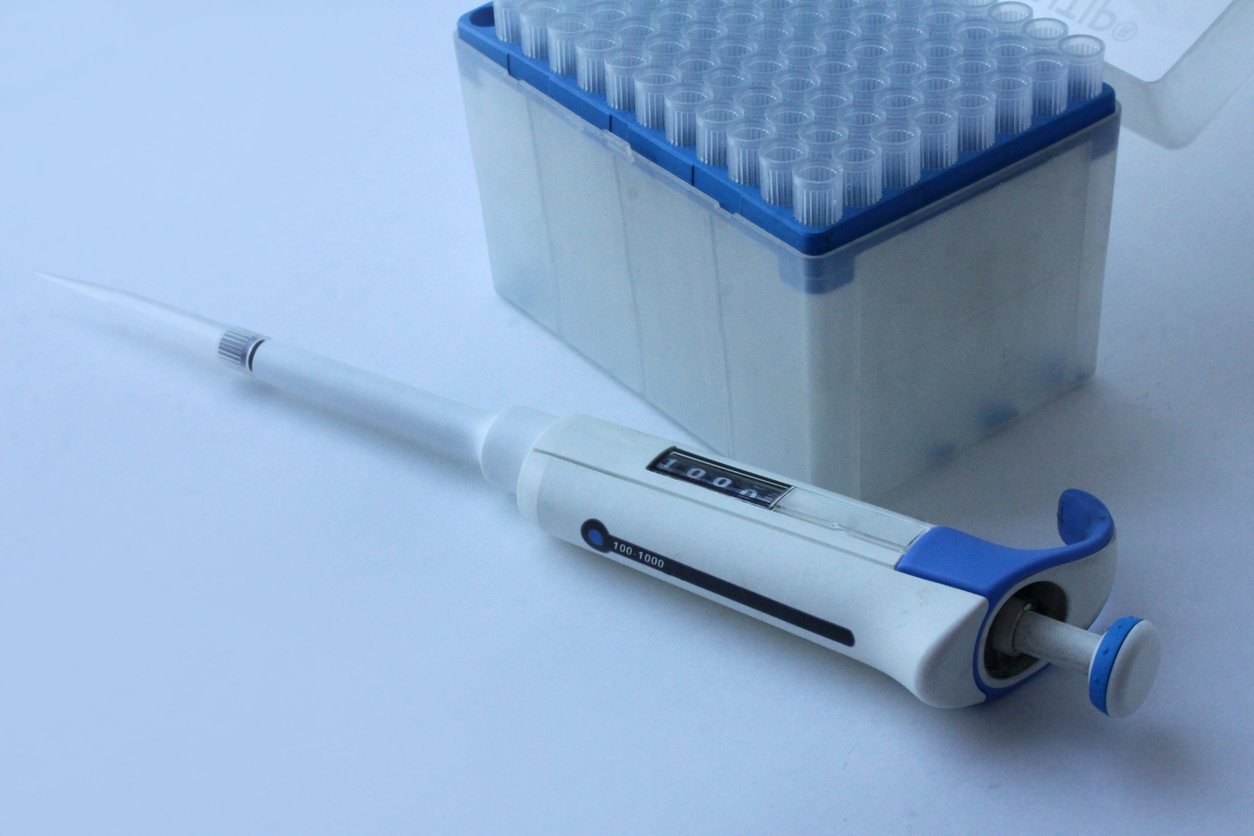

In any laboratory, ensuring accuracy and reliability in experimental results is vital. One of the key components in maintaining such standards is effective pipette management. When adhering to Good Laboratory Practice (GLP), laboratories must maintain precise records of equipment usage and their condition. However, this can be challenging due to the high number of pipettes, the consistent maintenance schedules and pipettes often change hands throughout the lab. This is where barcoding can play a critical role in tracking pipettes and ensuring compliance with GLP guidelines.

Pipettes are indispensable tools in laboratory science, and their proper management directly affects a laboratory’s accuracy. GLP requires laboratories to follow stringent protocols for equipment calibration, maintenance, and usage. This includes maintaining an organized and accountable system for tracking each pipette’s condition and performance. Failing to do so could compromise data integrity, leading to inaccurate results and potential regulatory issues.

Pipette Tracking with Barcodes

One of the most effective ways to track pipettes is by using barcode labels, which can also be enhanced with color coding for better organization. Barcoding each pipette allows laboratories to quickly scan and log essential information such as the pipette’s serial number, calibration history, maintenance status, and user assignments. Adding color to the labels helps visually categorize pipettes. This combination enhances data entry efficiency, while also reducing the risk of human error that can occur with manual recording.

Benefits of Barcoding Pipettes

- Accurate Record Keeping: Barcodes make it easier to track pipette usage and maintenance history. By scanning the barcode, you can instantly update an electronic log with precise details about calibration, maintenance and repairs.

- Improved Organization: With barcoded pipettes, each item can be tracked to specific workstations or staff members. This reduces the risk of misplacement and ensures pipettes are returned to the correct location.

- Time Efficiency: Scanning barcodes is much faster than manual data entry, saving time during pipette inspections, maintenance checks, or audits. This increases productivity and supports faster experimental turnaround times.

- Better Compliance: Maintaining an organized and accurate system for tracking pipettes is essential for adhering to GLP guidelines. Barcodes ensure that pipettes are properly tracked for calibration and usage, helping laboratories maintain compliance with regulatory bodies.

In summary, the use of barcoding to track pipettes in laboratories is a significant step in ensuring GLP compliance. By integrating barcodes into pipette management systems, laboratories can streamline workflows, reduce errors, and stay compliant with industry standards. Whether for routine maintenance, calibration checks, or audits, barcoding simplifies the process and supports the high standards of quality that are essential in scientific research.

Looking to start barcoding your laboratory’s pipettes? Let’s talk about how Computype can help.

Connect with our labelling experts today

Blog article form

"*" indicates required fields