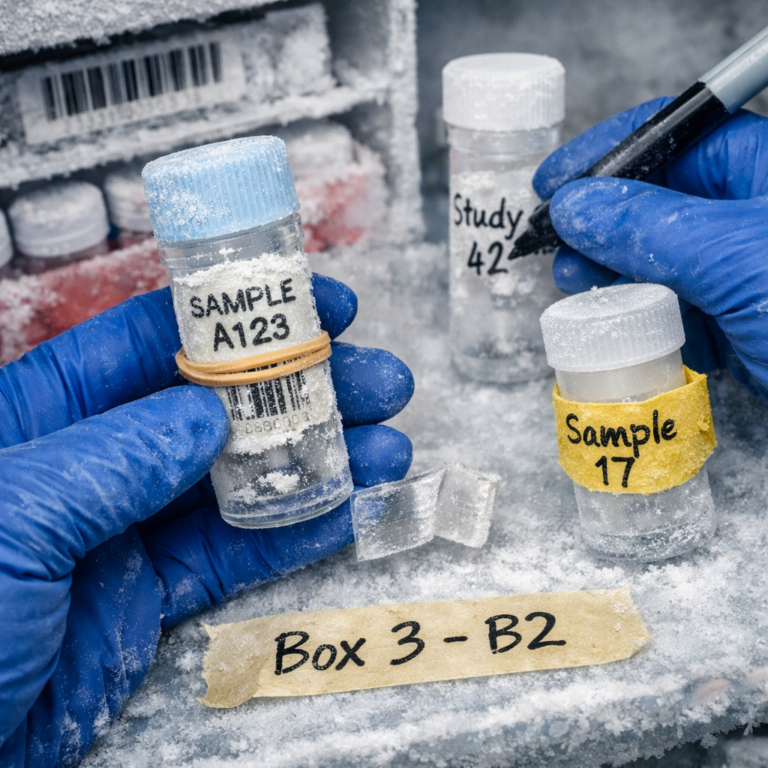

In cryogenic environments, labels are expected to survive some of the harshest conditions found in the lab, including ultra-low temperatures, long term storage, moisture, and repeated handling. When they do not, lab teams often do what they must do to keep work moving.

Rubber bands. Tape. Secondary containers. Sharpie backups.

These workarounds are common and understandable, but they come with real risks that often go unnoticed until something goes wrong.

The Reality of Cryogenic Label Workarounds

When a label starts lifting, cracking, or becoming unreadable in cryogenic storage, lab teams rarely stop their workflow to rethink labeling altogether. Instead, quick fixes are introduced to compensate for poor label performance, such as:

- Securing labels with rubber bands or tape to keep them from peeling

- Writing backup information directly on tubes or vials

- Over labeling with secondary identifiers

- Relying on container position or storage location for identification

These solutions may feel harmless, but they quietly introduce new points of failure into an already sensitive process.

The Risks Behind the Quick Fix

Cryogenic storage is often tied to high value samples, long term studies, or irreplaceable materials. When workarounds are used, the risks extend far beyond label aesthetics.

- Sample misidentification caused by rubber bands or tape shifting, falling off, or obscuring critical information

- Barcode failures due to over labeling or surface distortion that impact scannability

- Contamination concerns from adhesives, tape residue, or loose materials in storage environments

- Process inconsistency when each technician solves the problem differently

- Downstream errors that can lead to inventory mistakes, data integrity issues, or study delays

In regulated or high throughput environments, these risks compound quickly.

Why Labels Struggle in Cryogenic Conditions

Not all labels are designed for cryogenic storage, even if they claim to be. Common causes of failure include:

- Adhesives that lose flexibility or adhesion at ultra-low temperatures

- Label constructions that shrink, crack, or lift during freeze thaw cycles

- Poor conformity to curved labware such as vials, tubes, and straws

- Materials that cannot withstand long term exposure to liquid nitrogen vapor or deep freeze storage

When labels are pushed beyond their design limits, workarounds become inevitable.

A Better Approach: Labels Designed for Cryogenic Reality

Instead of compensating for label failure, cryogenic workflows benefit from labeling solutions engineered specifically for these environments.

Purpose built cryogenic labels are designed to:

- Maintain adhesion at ultra-low temperatures

- Conform tightly to curved labware without lifting or flagging

- Preserve barcode readability throughout storage and handling

- Eliminate the need for secondary securing methods or manual backups

When labels perform as intended, technicians do not need to invent fixes and processes remain clean, consistent, and reliable.

How Computype Supports Reliable Cryogenic Labeling

Computype designs cryogenic labeling solutions to perform in real lab environments, not just under ideal conditions. Our materials, adhesives, and constructions are selected and tested to withstand ultra-low temperatures, freeze thaw cycles, and long term storage without relying on workarounds.

We support cryogenic workflows by offering:

- Labels engineered for secure adhesion in cryogenic and ultra-low temperature storage

- Constructions that conform to curved labware and remain stable over time

- Barcode and human readable printing that stays legible throughout storage and handling

- Pre labeled labware and labware preparation services that reduce manual handling and variability

- Solutions compatible with both manual workflows and automated labeling systems

By addressing the root causes of label failure, Computype helps labs eliminate the need for rubber bands, tape, or secondary identifiers. The result is a cleaner workflow, improved consistency, and greater confidence that samples remain identifiable from collection through long term storage.

Supporting Cryogenic Workflows, Not Just Labels

Effective cryogenic labeling is not just about materials. It is about understanding how samples move through real lab environments. From pre-labeling and labware preparation to automation compatibility and long-term storage performance, the right solution removes risk instead of adding steps.

By replacing workarounds with proven cryogenic labeling solutions, labs can protect sample integrity, improve efficiency, and reduce the hidden costs associated with label failure.

Reach out to us to talk through your cryogenic workflow and get a labeling solution that eliminates workarounds.

Connect with our labelling experts today

Blog article form

"*" indicates required fields