Ensure your products remain clearly identified and traceable, even in the harshest cold storage environments. Withstand extreme cold, moisture, frost, and liquid nitrogen without losing adhesion or readability. Industries from biobanks to logistics rely on our solutions to protect their inventory. With durable materials and advanced adhesives, these labels maintain performance through freeze-thaw cycles and long-term storage.

Labeling for cold storage involves unique requirements that ensure the integrity and traceability of products. Extreme temperatures, moisture, frost, and repeated freeze-thaw cycles can all impact label performance. It’s essential to understand these factors to select the right labels and adhesives for cold storage applications.

Industries relying on cold storage prioritize accuracy, durability, and efficiency to ensure smooth operations in extreme conditions. Labels must align with these values, supporting seamless tracking, compliance, and product integrity. Each application brings unique demands that require tailored solutions to meet critical objectives.

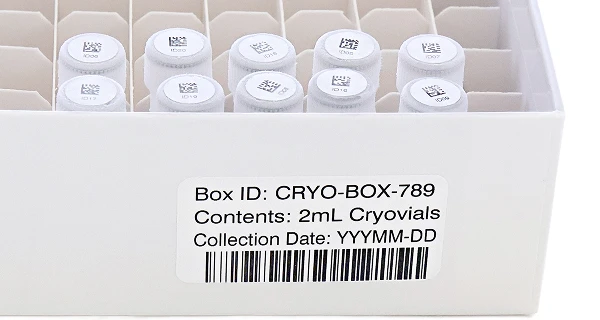

Cryo labels play a critical role in biobanking and biomedical research, ensuring the accurate identification of samples stored at ultra-low temperatures. Biological materials like tissue, blood, DNA, RNA, and cell cultures are often preserved in liquid nitrogen or ultra-low freezers for long-term studies and diagnostics.

In aerospace and engineering, cryo labels are essential for identifying and tracking components subjected to extreme temperatures. Applications include marking cryogenic fuels, materials, and parts used in research, testing, and manufacturing. These labels must endure harsh conditions without compromising adhesion or readability.

Cryo labels are vital for transporting perishable goods, biological samples, and industrial gases in cold chain logistics. Designed to endure extreme cold and condensation, they maintain clear identification throughout the shipping process. These labels ensure regulatory compliance and accurate handling in critical supply chains.

Choosing the right label material for extreme cold storage is crucial to maintaining the integrity and traceability of your samples. Our specialized label materials are designed to perform reliably in the harshest conditions, from ultra-low temperature freezers to vapor and liquid nitrogen storage. Below, you’ll find a detailed overview of our top-performing materials, each tailored to specific cold storage environments to ensure optimal adhesion, durability, and readability.

Engineering and testing label materials for high-performance cryo labels require precise attention to extreme environmental factors. Materials must withstand ultra-low temperatures, often down to -196°C, without losing adhesion or readability. Adhesives are formulated to bond securely to frost-covered or low-surface-energy surfaces, ensuring reliability in cold storage.

Face stocks like polypropylene and polyethylene are chosen for their durability and resistance to cracking or peeling under repeated freeze-thaw cycles. Rigorous testing simulates real-world conditions, including liquid nitrogen immersion, vapor phase storage, and condensation exposure. Thermal transfer printing is often used to ensure barcodes and text remain legible despite harsh conditions.

Explore our cryo label shop including liquid nitrogen labels and labels for frozen surfaces.

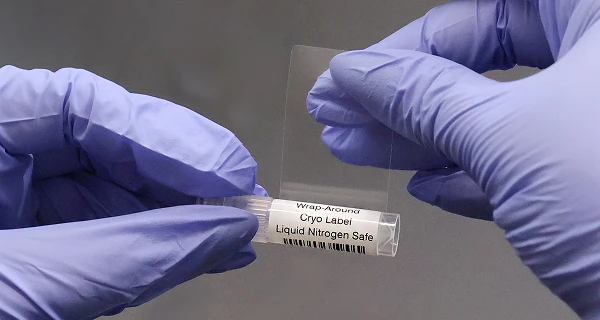

Cryogenic labels are crafted to withstand extreme environments, including both vapor and liquid nitrogen storage. Custom adhesives ensure a strong bond even on frozen surfaces, providing reliable performance at ultra-low temperatures. Durable, chemical-resistant face stocks enhance the longevity of the labels in harsh conditions. Top-coated materials offer added protection and improve printability, keeping important information clear and intact.

Rubber and acrylic adhesives are engineered for cryogenic conditions. They bond strongly in extreme cold, even on frozen surfaces. Whether flexible rubber or durable acrylic, these specialty adhesive formulas keep labels securely in place.

Laminates offer extra protection for cryo labels in extreme environments. The wrap-around laminate shields the printed image from damage, even in liquid nitrogen. It boosts durability and keeps the label clear and readable over time.

To address cold storage labeling effectively, it is necessary to consider specific environmental stressors. Labels must resist not only low temperatures but also the physical stress of handling and storage conditions. Additionally, adhesives must maintain their bond and flexibility without becoming brittle.

Flash freezing rapidly cools products to extremely low temperatures, creating a challenging environment for label materials. Advanced adhesives are engineered to bond instantly and maintain flexibility during the sudden temperature drop, preventing cracking or peeling. Durable face stocks complement these adhesives, ensuring labels remain intact throughout the flash freezing process.

Label materials for frozen tubes require specialized adhesives that bond securely to cold, frost-free surfaces. Wrap-around designs enhance attachment by adhering to themselves rather than the tube, ensuring durability in extreme conditions. Selecting materials that tolerate low temperatures and preparing surfaces properly are critical for maintaining sample identification.

Thermal cycling exposes label materials to repeated freezing and thawing, demanding exceptional durability. High-performance adhesives and resilient face stocks are designed to withstand these cycles without cracking or peeling. Materials must retain adhesion and legibility through fluctuating temperatures to ensure reliable identification over time.

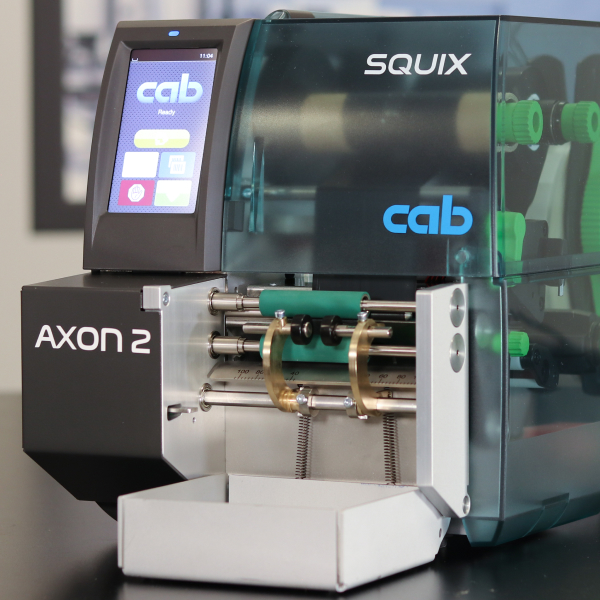

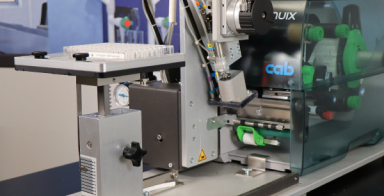

Automating the labeling process in cold storage environments requires labels specifically engineered to perform under both automated application and extreme conditions. Cold storage labels must not only withstand low temperatures but also function seamlessly with automated applicators. This dual requirement makes the design and engineering of these labels particularly challenging.

Applying cold storage labels correctly is essential for ensuring their performance and durability. Following best practices helps prevent common issues like peeling, smudging, and loss of adhesion. Here are some key tips to ensure your labels remain secure and legible in cold storage environments:

Application temperature is the range within which a label can be applied to a surface and the adhesive will bond properly. In contrast, the operating temperature is the range of temperatures that the label can withstand once applied. For instance, a label designed to endure temperatures as low as -80°C may require an application temperature of -20°C or higher to ensure proper adhesion.

If labels are applied outside their specified application temperature range, the adhesive may not bond effectively, leading to label failure. Ensuring labels are applied within their application temperature guarantees they will perform successfully and endure their promised operating temperatures, maintaining reliability and traceability in cold storage environments.

For labs that prefer to label their own vials, it’s crucial to use the right labels, printers, and applicators to ensure precision and compatibility with chromatography equipment. Proper barcode placement is essential for seamless integration into automated systems and accurate sample tracking. Choose high-quality materials that can withstand the chemical and environmental conditions of chromatography processes.

High-quality label printing ensures that all essential information is accurately conveyed on every sample. By using durable materials and advanced inks your labels remain legible and intact. Custom printing allows you to include barcodes, color-coding, and detailed text.

Streamlining label application with automatic tube and plate labelers enhances efficiency and accuracy in your lab. Automated labelers reduce the risk of human error, ensuring that each label is applied precisely and consistently, regardless of sample volume.

The Axon 1 applicator is designed for high-speed, precise vertical labeling of tubes in cold storage environments. Our labels for the Axon 1 are engineered to maintain adhesion and legibility, ensuring each label is applied accurately and consistently, even in ultra-low temperatures.

For more complex labeling tasks, the Axon 2 offers advanced capabilities for horizontal labeling of tubes. Our cold storage labels for the Axon 2 are developed to handle its sophisticated application processes while maintaining durability and readability in extreme temperatures.

The SQUIX printer with the S3200 applicator is specifically designed for labeling microplates with precision and flexibility. Our labels compatible with the Squix S3200 are crafted to ensure they adhere properly and remain legible, even in the harsh conditions of cold storage.

Cryo labels remain durable in extreme cold conditions. Ideal for long-term storage of samples at ultra-low temperatures.

PCR labels provide clear identification for small tubes used in thermal cycling. They are designed to withstand the high temperatures of PCR processes.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields