GHS labels are essential, whether you’re labeling primary drums, secondary bottles, or labware. We provide compliant, durable solutions tailored to you.

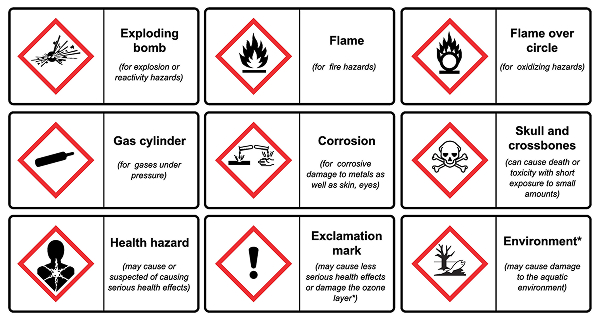

Standardized pictograms, signal words, and hazard statements

Durable materials built for harsh industrial environments

Compatible with two-ribbon printers for red and black output

Go beyond the minimum—streamline compliance, improve safety, and gain flexibility in how you label hazardous materials.

GHS labels are required on all containers holding hazardous chemicals, from manufacturer packaging to secondary workplace bottles. Labeling ensures that workers, transporters, and end users can clearly understand the risks associated with each substance. These requirements apply across manufacturing, laboratory, and logistics environments.

GHS applies to both supplier-filled containers and those that are filled or mixed in the workplace. Primary containers include the original packaging such as drums or jugs, while secondary containers refer to smaller bottles, cartridges, or labware used internally. Both require durable, legible labels that remain intact during handling and storage.

Drums, jugs, and IBC totes for storage

Spray bottles and workplace squeeze bottles

Lab vials, reagent bottles, and cartridges

Boxes and pallets used for shipping chemicals

These include large-volume containers like drums, totes, and tanks used to store raw materials or chemical inventory. Labels must remain legible despite exposure to chemicals, abrasion, and environmental factors like moisture or temperature shifts. GHS labels on these containers are typically larger in size and require strong adhesives to stay in place over time.

Small bottles, spray dispensers, squeeze bottles, and similar workplace containers are often used for daily operations or maintenance. These are considered secondary containers and must be labeled when filled with hazardous chemicals, even in diluted form. Labels in this category must be compact, durable, and able to withstand frequent handling and cleaning.

Labware such as vials, reagent bottles, cartridges, and small-volume vessels are commonly labeled during in-house mixing, sampling, or storage. GHS labels for these items must be chemically resistant and stay intact through heating, cooling, or contact with solvents. Print clarity and adhesive reliability are critical to maintaining compliance and traceability in regulated environments.

All GHS-compliant labels must follow a standardized format that clearly communicates chemical hazards. This includes specific elements such as pictograms, signal words, hazard statements, and product identifiers. Understanding both the content requirements and production strategies is key to maintaining regulatory compliance.

GHS labels use globally recognized formatting to ensure hazards are understood regardless of language or location. Each label must contain six core components, and omissions or inconsistencies can result in non-compliance. Labels should be legible, durable, and appropriately sized for the container they’re applied to.

Signal word to indicate severity (e.g., Danger)

Pictograms inside red diamonds to show hazards

Hazard and precautionary statements for safety

Product identifier and supplier contact details

Signal words like “Danger” or “Warning” convey the level of risk associated with the chemical. They must be clearly printed and used consistently based on the classification of the substance.

Each hazard class is associated with a specific pictogram framed in a red diamond. These are required even on small containers unless an exemption applies.

Hazard statements, precautionary statements, product identifiers, and the supplier’s name and address must all be present. This information provides instructions for safe handling.

Ensure your labels meet every requirement—with materials, formats, and print strategies tailored to your needs. Fill out the form and our team will help you find the most effective solution for your workflow.

There are multiple ways to produce GHS labels, from printing them entirely in-house to ordering fully pre-printed rolls. Many operations use a hybrid strategy, with red diamonds pre-printed and black data added as needed. The right approach depends on your chemical inventory, labeling volume, and the resources available at your facility.

In-house printing for dynamic and variable content

Pre-printed rolls for known, high-volume chemicals

Hybrid options to reduce color printing complexity

Custom materials optimized for your workflow

The cab XC Q printer is a powerful solution for on-demand GHS label printing. Designed for two-color labels, it prints GHS-compliant labels in high resolution, ensuring durability and clarity. With its ability to print red pictograms and black text in a single pass, the XC Q is ideal for in-house production of GHS labels.

The XC Q is especially well-suited for chemical manufacturers, distributors, and labs that need flexibility without sacrificing compliance. Its dual-ribbon system reduces labeling errors by eliminating the need for multiple print runs or manual alignment of red diamonds.

The printer works with a wide range of durable label materials, including synthetics designed for chemical resistance. Integration is simple with common label design software, and the XC Q is compatible with both blank and partially pre-printed stock.

Our professionally printed GHS labels ensure regulatory compliance and long-term durability while offering extensive customization options. Using advanced flexographic and digital printing methods, we produce high-quality labels that perform reliably in harsh environments.

Expert printing solutions for customized hazard communication.

Custom printing allows for tailored layouts, branded elements, and industry-specific adjustments to meet your exact needs. Our flexible approach ensures that each label is both compliant and aligned with your visual standards.

Add logos or company-specific branding to GHS labels

Customize label sizes for containers of any shape

Select materials designed for chemical and environmental resistance

Create multi-language labels to meet international standards

Our print processes support full-color output, producing crisp pictograms and legible hazard statements. With fast turnaround and scalable production, we support everything from short runs to high-volume labeling programs. Whether you’re labeling industrial chemicals or laboratory reagents, our pre-printed labels deliver durability, clarity, and confidence.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields