Pre-printed labels eliminate uncertainty in critical applications. Every label is engineered for readability, durability, and compliance from the start.

These labels combine design expertise with precision manufacturing. The result is consistent performance that protects processes, data, and assets across demanding environments.

Pre-printed labels combine advanced printing, engineered inks, and precise design to ensure accuracy and resilience under demanding conditions. By controlling every detail from serialization to surface adhesion, these labels outperform on-site printing and deliver consistent performance across laboratories, warehouses, industrial production, and regulated environments.

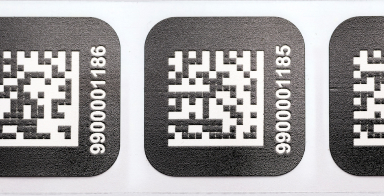

Accurate serialization is the foundation of reliable labeling. Pre-printed labels guarantee unique codes, eliminate duplicates, and maintain sequence control throughout production runs. This ensures traceability across supply chains, reduces compliance risks, and protects against costly errors in regulated and high-volume environments.

Pre-printed labels withstand harsh environments better than in-house printed labels. Engineered inks, coatings, and ribbons resist abrasion, chemicals, temperature extremes, and handling stress. This durability ensures data and graphics remain legible for the full lifecycle of the asset or sample.

Readable, balanced design is critical for fast identification. Pre-printed labels use precise imaging and layout optimization to maximize barcode scannability and information legibility. This clarity minimizes user error, accelerates workflows, and supports efficient asset management in laboratories, warehouses, and production facilities.

We employ multiple printing technologies to achieve unmatched accuracy and flexibility in label production. Each method offers distinct advantages, from color control to durability, and we pair them with precise converting and finishing. This ensures every label meets technical requirements and functions flawlessly in application.

Digital offset uses liquid electrophotography to produce smooth gradients and consistent, repeatable spot colors. The process integrates inline priming and top-coating to enhance adhesion, printability, and environmental durability. Compared with flexo, it excels at variable data, micro-text, and serialization in long sequences.

Inkjet propels resin-rich inks directly onto substrates, creating dense images resistant to abrasion and solvents. Integrated vision systems monitor droplet placement, ensuring registration accuracy across multi-panel and high-coverage designs. Compared with thermal transfer, it enables vivid CMYK imaging with greater throughput and chemical durability.

Hybrid integrates digital CMYK imaging with flexo spot-color layers and protective varnishes in one pass. It optimizes unit cost by assigning static content to flexo and variable data to digital. Compared with stand-alone systems, hybrid provides unmatched flexibility for brand graphics combined with serialization accuracy.

Flexographic printing relies on relief plates transferring ink to the substrate via precise rotary stations and anilox rolls. The method supports specialty inks, including fluorescents and thermochromics, expanding functionality beyond visual identification. Compared with digital, it delivers lower unit cost on longer runs while maintaining consistent brand colors.

Thermal transfer uses heat to bond ribbon coatings onto engineered topcoats, forming resistant monochrome images. It supports resin, wax-resin, and specialty ribbons tailored for chemical durability, abrasion, or extreme temperature use. Compared with digital, it excels at small batch or in-house variable data with precise symbol grading.

Request a sample tread label to see how clarity, compliance, and clean removal support effective communication across every tire category.

Variable data printing generates unique content such as barcodes, serial numbers, or graphics on every label. It depends on digital processes—primarily digital offset, digital inkjet, or thermal transfer — because these can change output on the fly. Flexographic presses alone cannot produce variable elements without digital integration. Success requires serialization controls, duplicate prevention, and inline verification systems to ensure data integrity and readability across the entire run.

Static printing, also called fixed image printing, repeats one design across an entire run. It emphasizes consistency, repeatability, and cost efficiency. Flexographic printing excels here, producing long runs with lower unit costs. Digital offset or inkjet handle shorter static runs where turnaround speed matters. Success comes from color stability, plate accuracy, and tight registration. Static printing is essential when every label must present identical brand marks.

Color printing involves reproducing CMYK process images or PMS spot colors to exact specifications. HP Indigo digital excels at gradients, microtext, and photographic detail, while flexo achieves unmatched PMS spot-color consistency at scale. Hybrid systems combine both strengths. Color printing success depends on calibration, proofing, and protective coatings to resist abrasion, chemicals, and fading. Accurate color maintains brand integrity and ensures scannable codes.

Selecting digital printing for short runs and flexographic printing for long runs ensures cost efficiency, consistent quality, and reliable label performance.

Align facestock and adhesive chemistry with compatible printing processes to guarantee durability, adhesion, and high-quality imaging in challenging environments.

Control serialization and barcode quality with collision-proof generators and real-time verification tools to eliminate duplicates, skips, and unreadable labels.

From digital offset to hybrid flexo systems, we leverage multiple print technologies to match resolution, ink chemistry, and volume — giving each label the durability, clarity, and efficiency the application demands.

Inks and coatings determine how well labels perform under stress, from adhesion to readability. UV, solvent, and aqueous chemistries each serve different substrates and conditions, while primers enhance receptivity. These elements make pre-printed labels more durable, accurate, and consistent across demanding industrial and laboratory applications.

UV-cured inks polymerize instantly under ultraviolet or LED light, creating highly durable images on films, foils, and synthetics. Used in flexographic and hybrid digital presses, they excel at vibrant color, abrasion resistance, and rapid production. Their immediate curing enables inline finishing, reducing downtime and supporting complex multi-layer pressure-sensitive label constructions.

Solvent-based inks dissolve resins and pigments in volatile carriers, evaporating quickly to leave durable printed images. Flexographic presses primarily use them for non-porous substrates like films, foils, and plastics. They deliver strong adhesion and chemical resistance but require careful handling due to VOC emissions and regulatory considerations during production.

Water-based inks suspend pigments in water and resin, making them lower in VOCs and safer to handle. Common in flexographic printing for porous substrates, they offer reliable color reproduction and reduced environmental impact. Drying speed depends on substrate and press setup, sometimes requiring pre-coats or energy-assisted curing systems.

Primers and precoats prepare facestocks to accept inks with maximum durability and clarity. They improve surface energy, enabling stronger bonds between ink and substrate. Crosslinked layers reduce ink slip, prevent beading, and preserve image definition. This results in sharper barcodes, truer colors, and longer-lasting performance in challenging environments.

Increase surface energy for stronger adhesion.

Enable chemical crosslinking for durable bonds.

Improve sharpness and print definition.

Primers form chemical crosslinks with inks, ensuring printed images withstand abrasion, solvents, and temperature cycles without degradation or loss of readability.

By optimizing surface energy, we guarantee inks spread evenly, preventing voids, streaking, or color shifts that compromise barcode accuracy or brand consistency.

Engineered layers lock inks in place, producing sharp edges, high contrast, and stable color even on challenging substrates like plastics or foils.

Not all labels are built the same. Share a few details about your product or environment, and we’ll recommend a label designed to stick, stay readable, and hold up under pressure.

Accurate color is essential for brand recognition, regulatory compliance, and scannability. We combine calibrated print technologies, advanced ink systems, and protective finishes to achieve reliable results. Every color run is verified against standards, ensuring consistent reproduction whether labels are printed in short batches or high-volume production.

Full color printing uses CMYK builds to reproduce photographs, gradients, and detailed graphics with precision. Digital technologies like Indigo and inkjet excel at capturing subtle tones and fine detail. Successful results require calibrated presses, consistent substrates, and protective finishes to maintain vibrancy under handling, abrasion, or environmental exposure.

Custom spot colors are pre-mixed inks designed to match brand specifications exactly, often defined by PMS standards. Flexographic printing leads in spot color consistency, while hybrid systems combine spot layers with digital content. Achieving reliable matches depends on rigorous ink mixing, proofing, and ongoing monitoring against approved references.

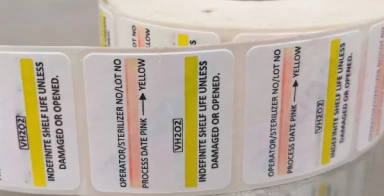

Variable color data applies unique color elements to each label, such as color-coded categories or serialized images. Digital presses enable on-the-fly adjustments without plates, supporting short runs or highly personalized projects. Maintaining accuracy requires integrated workflows and real-time validation to ensure consistent reproduction across dynamic color variations.

We regularly calibrate digital and flexographic presses using spectrophotometers and reference targets to maintain predictable, repeatable color reproduction across substrates and production runs.

We use ink mixing systems and PMS standards, confirming every spot color through controlled proofing and ongoing monitoring against approved brand specifications.

We apply topcoats and varnishes to resist fading, abrasion, and chemical attack, preserving both brand accuracy and barcode readability over time.

Labels carry essential data that must remain accurate and legible throughout their use. From barcodes and serialized sequences to compliance marks and branding, every element demands precision. We combine advanced printing, verification, and quality controls to ensure each piece of information is consistently reproduced without error.

We design layouts that integrate barcodes, text, and symbols without overcrowding, ensuring every element remains legible, scannable, and functionally reliable.

We optimize spacing, scaling, and font selection so data, logos, and compliance marks fit within available dimensions without sacrificing readability.

We engineer designs that streamline scanning, identification, and handling workflows, improving speed, accuracy, and compliance across demanding laboratory, industrial, and logistics environments.

Barcodes require high-resolution imaging and strict grading to remain scannable across supply chains. Linear codes like Code 128 demand sharp edges, while 2D symbologies such as Data Matrix and QR codes need uniform contrast. Success depends on precise calibration, validated sequence control, and coatings that protect readability against abrasion or chemical exposure.

Custom text ranges from simple identifiers to detailed instructions, often needing clear typefaces at very small sizes. Achieving sharp legibility requires optimized print resolution, ink adhesion, and substrate compatibility. Whether static or variable, text must remain stable under handling and environmental stress, ensuring critical information is accessible throughout the label’s lifecycle.

Alphanumeric sequences provide unique identifiers for tracking, lot numbers, and expiration dating. They require reliable variable data systems capable of collision-free serialization and tight placement accuracy. Consistent readability relies on matching font weight to resolution, while inline verification ensures sequence integrity. Protective finishes safeguard printed characters from wear, chemicals, and environmental exposure.

Logos and brand graphics demand exact color reproduction and consistent scaling across production runs. PMS spot-color matching, calibrated CMYK builds, and proofing systems maintain fidelity to brand guidelines. Printing success requires substrate-appropriate inks, protective coatings, and precise registration to prevent distortion.

Compliance symbols, such as CE, UL, or recycling marks, require precise scaling and long-term legibility to satisfy regulations. Flexo and digital presses achieve consistency through calibrated imaging and durable inks. Protection against abrasion, solvents, and UV ensures marks remain visible. Regular audits and verification confirm symbols meet required size and contrast standards.

Hazard symbols, including GHS pictograms and warning icons, must remain visible under harsh conditions where safety depends on clarity. High-contrast imaging ensures recognition, while coatings and substrates provide resistance to chemicals, abrasion, and moisture. Correct scaling, registration, and ink durability guarantee compliance with global hazard communication.

Regulatory identifiers like UDI, ISBT 128, or tire labeling codes require specialized print setups for compliance. They depend on variable data systems for serialization and grading tools for accuracy. Achieving compliance also demands ink durability and barcode clarity, ensuring labels meet industry-specific standards and maintain traceability throughout product lifecycles without failure.

Graphics such as fill lines, graduation marks, or optical sensor targets must print with exceptional precision. These elements rely on sharp imaging, proper contrast, and resistance to environmental stress to remain functional. Applications often demand fine registration control and coatings to protect against smudging or wear during equipment handling or laboratory use.

Security features such as microtext, UV-fluorescent inks, or serialized authentication codes add protection against counterfeiting and misuse. Printing these elements requires specialized technologies, precise resolution, and strict sequence control. Durability is critical—protective coatings and substrate compatibility ensure security marks remain intact, verifiable, and effective throughout a product’s distribution and use cycle.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields