Automated labeling systems transform lab workflows by delivering precision, speed, and consistency across a variety of labware. From semi-automated solutions for smaller tasks to fully automated systems for high-throughput environments, these tools reduce manual effort and improve accuracy. With options to meet specific lab needs, automated labeling is a powerful step toward a more streamlined, productive lab.

Laboratories handle vast amounts of samples daily, and manual labeling slows processes while introducing risk. Automated labeling systems integrate seamlessly into lab workflows, ensuring every tube, vial, and plate is marked with precision. With barcode-enabled automation, labs gain reliability, speed, and traceability—critical for both research and regulated environments.

Automated labeling accelerates sample preparation by eliminating manual bottlenecks. Hundreds of tubes or plates can be labeled in minutes, keeping pace with high-throughput environments. This efficiency allows technicians to spend less time labeling and more time on valuable research and analysis.

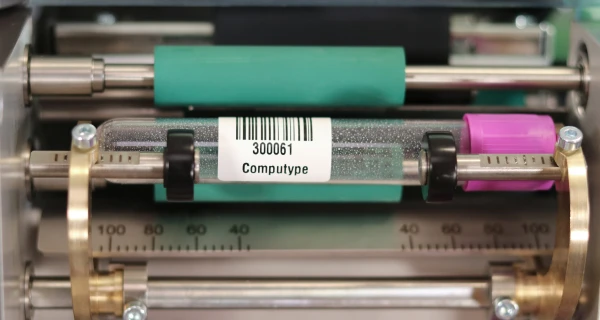

Mislabeling even a single tube can derail experiments. Automation ensures every barcode is applied consistently and read correctly, reducing human error. With precise placement and standardized print quality, labs can count on reproducible data integrity from the start of each workflow.

Barcodes enable seamless tracking of samples throughout the entire lab process. From collection to storage to testing, every movement is documented. This complete audit trail supports compliance, improves collaboration, and safeguards confidence in results—whether in clinical research or routine diagnostics.

When labs plan for automation, the focus often starts with instruments and robotics, but labels are just as essential. Every automated workflow depends on barcodes to identify, track, and connect samples across systems. Without consistent, reliable labeling, even the most advanced instruments can’t deliver accurate results. Automated label applicators ensure that barcodes are printed clearly and applied with precision, so scanners and robotic arms can read them without error.

Consistent placement eliminates misreads and reduces workflow interruptions. By starting automation with labels, labs establish a foundation for traceability and compliance. Barcode-driven labeling links samples seamlessly to data systems, creating the backbone for automated research and diagnostics. Prioritizing label automation helps ensure that every downstream process runs smoothly, efficiently, and with confidence.

Automation in labeling ranges from semi-automated systems to fully automated solutions, allowing labs to choose the level that best fits their workflow and volume. Choosing the right level of automation enhances productivity and accuracy across labeling tasks.

Choose the right level of automation to integrate with your lab.

Semi-automated systems reduce manual handling for smaller batches while providing reliable label placement. In contrast, fully automated systems offer hands-free operation for continuous labeling with minimal intervention.

With semi-automated options, labs maintain precision and flexibility while reducing manual workload. In fully automated systems, the hands-free functionality increases throughput and minimizes human error, making them ideal for large labs. Print-and-apply automation enables continuous labeling, efficiently managing high-volume tasks with consistency.

Tube labelers bring consistency and speed to one of the most repetitive lab tasks. By automating the application of barcode labels, labs ensure every tube is marked with precision, reducing errors and saving time. Automated tube labeling supports seamless sample tracking across instruments and workflows, making it an essential component of modern laboratory automation.

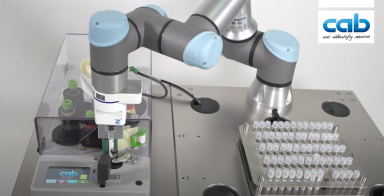

The Axon 1 labeler offers fully automated tube labeling for high-throughput labs. Its vertical tube orientation ensures accurate label placement without manual handling. Designed for flexibility, it accommodates both capped and uncapped tubes. The Axon 1 integrates with robotic systems and delivers high-resolution labels at 300 or 600 dpi.

The Axon 2 is a versatile labeler that simplifies automation with push-button or foot pedal controls. It’s easy to integrate into existing workflows, allowing labs to improve labeling speed and accuracy without complex setup. Supporting a variety of tube sizes, the Axon 2 ensures precise and consistent label application.

The Sci-Print VX2 automates tube handling and labeling, offering high-efficiency performance for busy labs. It supports a wide range of tube sizes and styles, ensuring accurate label placement for various applications. With its dual capability of labeling and sorting, the VX2 streamlines workflows and reduces manual intervention.

Automated tube labelers handle different diameters, materials, and capped or uncapped tubes with precision, ensuring consistent labeling across varied laboratory workflows.

Vertical orientation and precise placement make labeled tubes compatible with robotic arms, allowing seamless transfer, handling, and tracking in automated laboratory systems.

Instead of purchasing applicators, labs can rely on service-based automation—receiving pre-labeled tubes ready for immediate use, saving costs and setup time.

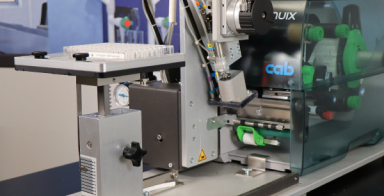

Plate labelers eliminate the time and error risks of manually labeling microplates. With barcode-driven automation, labels are applied consistently and with exact placement, even on narrow plate edges. Automated plate labeling ensures every sample set is traceable, improves workflow efficiency, and supports integration with robotic systems for high-throughput laboratory environments.

The S3200 is tailored for microplate labeling, applying durable labels with precision. It handles different microplate formats, ensuring labels are placed accurately for use with automated analyzers and plate readers. By automating this process, the S3200 boosts throughput and reduces errors, making it a reliable solution for high-volume labs.

The Sci-Print MP2+ is purpose-built for automated microplate labeling, delivering quick and precise label application across various plate formats. Designed to integrate smoothly into lab workflows, it ensures reliable label placement for high-throughput operations. The MP2+ boosts efficiency, enabling labs to easily meet rigorous demands.

Our advanced automation systems let you outsource labware labeling without investing in your own equipment. Available through our Labware Prep™ Services, it offers precise and efficient labeling for tubes and plates. This allows you to benefit from large-scale automation while focusing on core tasks.

Automated systems can apply barcodes to one or more sides of a plate, ensuring flexibility for different workflows and scanner orientations.

Plate labelers apply barcodes on small, uniform edges with accuracy, delivering reliable scanning performance and reducing labeling errors in high-volume labs.

Automated plate labeling supports robotic loading and handling, enabling seamless integration into existing lab automation systems and improving throughput across sample processing steps.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields