From durable materials to high-resolution printing, we ensure that every label is compliant with regulatory standards and tailored to your specific needs.

Whether you need flexibility for small production runs or large-scale pre-printed labels, our solutions provide both reliability and adaptability.

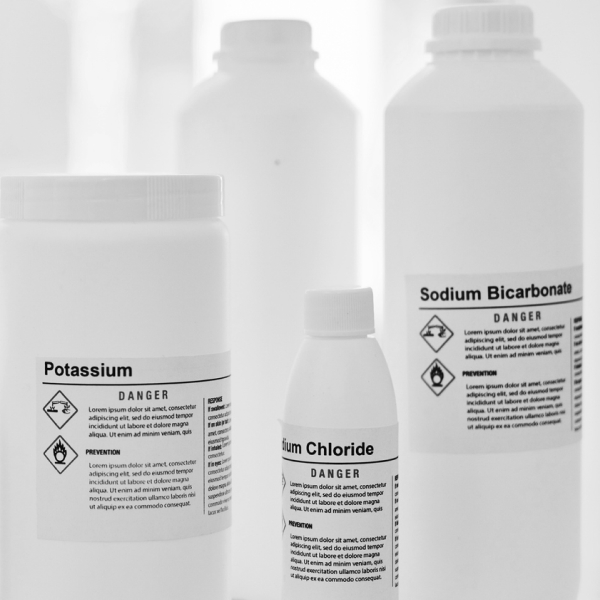

Labels must meet stringent regulatory standards, including those set by 21 CFR Part 820 and ISO standards, to ensure safety, accuracy, and traceability. These regulations are designed to protect manufacturers and end-users by ensuring proper hazard communication. Every label must include elements such as the product name, batch number, expiration date, and storage instructions.

In addition, labels must be resistant to environmental conditions to prevent degradation of critical information. Manufacturers must ensure that their labels meet regulatory audits, which can be triggered by incomplete or inaccurate labeling. Failure to comply can result in product recalls, fines, or even shutdowns, emphasizing the importance of adhering to these strict standards.

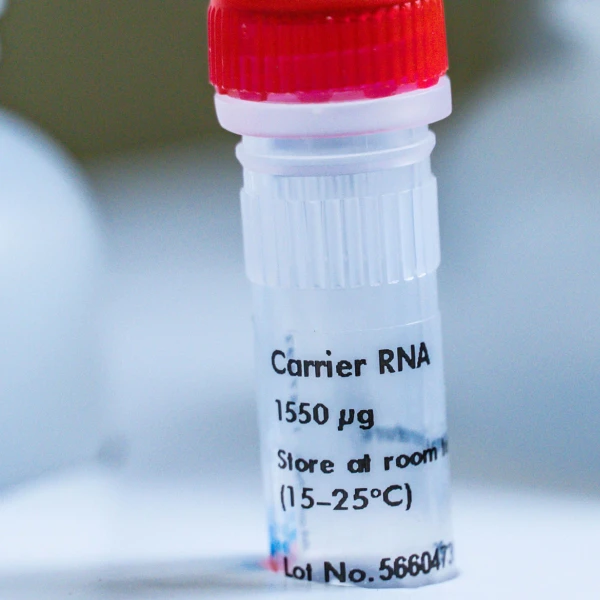

Reagent manufacturing labels must include essential information that ensures safety, traceability, and usability. The key elements provide the necessary details for proper handling and storage, ensuring compliance with regulatory guidelines. These elements are critical for protecting end-users and product integrity.

Durability is vital for reagent manufacturing labels, as they must withstand exposure to chemicals and environmental factors. The materials chosen need to provide long-term legibility and adhesion in challenging conditions. Proper material selection ensures that the label remains intact throughout the reagent’s lifecycle.

Durable labels for long-lasting performance.

Labels must resist smudging, fading, or peeling when exposed to moisture, chemicals, or temperature changes. Material options should align with the specific requirements of the reagents and their storage environments.

Selecting the right material enhances the overall durability and reliability of the labels. By ensuring that labels are tough enough for the storage and handling environments, manufacturers can prevent the loss of critical information over time. Properly chosen materials reduce the need for relabeling, minimizing costs and risks of non-compliance.

Pre-barcoded labware offers a streamlined solution for reagent manufacturing, improving traceability and operational efficiency. By pre-marking labware with custom text, graphics, and grad lines, you can enhance both functionality and compliance. Labware can be customized with expiration dates and other specific details tailored to your production requirements. Pre-marked labware reduces manual intervention, minimizing errors and saving time across manufacturing.

Pre-barcoded labware enhances traceability by integrating seamlessly with inventory management systems. This allows for automated tracking and real-time visibility, reducing errors and improving efficiency.

Customization options ensure your labware is tailored to meet specific production and regulatory needs. From custom text and graphics to expiration dates and grad lines, every detail can fit your exact needs.

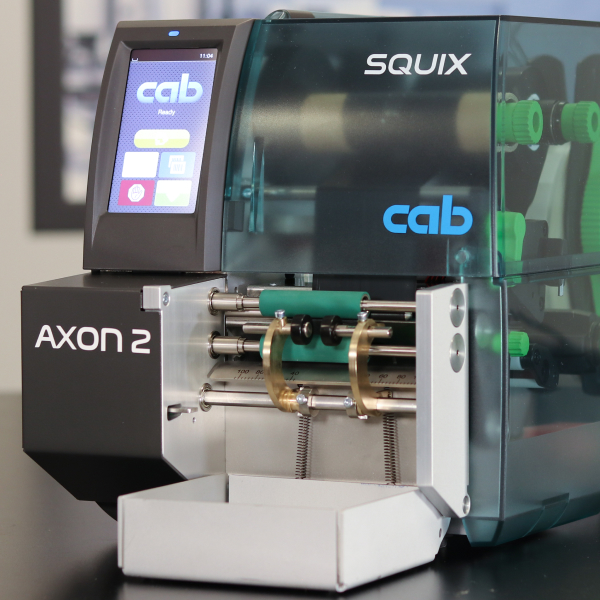

In-house labeling solutions provide manufacturers with the control and flexibility needed to produce high-quality labels on demand. Our in-house solutions offer a range of capabilities, including automated printing systems that improve efficiency and accuracy. We also provide support for integrating RFID technology to enhance traceability and security. These solutions allow manufacturers to manage their labeling process more effectively while maintaining high standards of compliance.

Automation improves labeling accuracy by minimizing manual errors and streamlining the production process. It enhances productivity by speeding up label generation and reducing errors.

RFID enhances real-time inventory tracking and improves overall product visibility. It also enables secure data storage, providing accurate, automated traceability throughout the supply chain.

Ready to customize your reagent labels? Fill out the form below, and our team will help you find the perfect solution for your requirements.

Reliable labels for tubes and vials ensure accurate identification in demanding labs. Withstand freezing, chemicals, and repeated handling.

Durable cryo labels for frozen storage maintain adhesion and readability at ultra-low temperatures. They resist frost, moisture, and harsh lab conditions.

The cab XC Q printer delivers precise two-color printing for safety and compliance labels. It handles high-volume tasks with efficiency and clarity.

© Computype 2024

© Computype 2024

"*" indicates required fields