Receive pre-barcoded, directly marked, and workflow-ready labware tailored to your needs. Labware Prep™ Services streamline labeling, support automated processes, and reduce variation by delivering prepared labware ready for immediate use in high-throughput or regulated environments.

Optimize your laboratory workflow with Labware Prep™ Services—an all-in-one solution for preparing tubes, vials, plates, and specialty labware for immediate use. Labware can be pre-barcoded, directly marked, tare weighed, filled, capped, sorted, arranged sequentially, kitted, and packaged according to your requirements.

This preparation elevates operational efficiency by reducing hands-on labeling, minimizing errors, and ensuring every container arrives workflow-ready. With options built for cryogenic storage, contamination-sensitive environments, and high-throughput screening, Labware Prep™ aligns with your specific research and production needs. Streamline your processes and enhance productivity with customized labware preparation designed for reliable, repeatable laboratory operations.

Explore the key steps behind Labware Prep™ Services. This video shows how barcoding, weighing, sorting, and kitting come together to create labware that arrives organized, documented, and ready for your workflow. Each stage supports consistent identification, reduces manual preparation, and helps maintain reliable performance across routine and high-throughput laboratory processes.

Labware Prep™ Services provide complete preparation for tubes, vials, plates, and specialty containers before they enter your workflow. Options include pre-barcoding, direct marking, tare weighing, cleanroom preparation, procurement, sorting, and kitting. Each service supports consistent identification, accurate measurements, and efficient setup, ensuring labware arrives ready for immediate use across manual and automated laboratory environments.

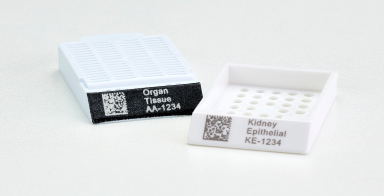

Pre-marked labware provides reliable, ready-to-use identification without any in-house labeling. Barcodes, alphanumeric sequences, grad lines, logos, and color elements are permanently applied using technologies suited to your environment and container type. This supports consistent placement, reliable scanning, and stable imaging through cryogenic storage, solvent exposure, and automated handling.

Tare weighing establishes reliable baseline measurements for tubes, vials, plates, and specialty labware. Each item receives a documented tare value, ensuring precise downstream calculations and consistent inventory tracking. Weight stability varies by marking method, so pre-marked or directly imaged labware maintains more predictable mass than adhesive labels, which may shift with temperature.

Kitting and sorting streamline complex workflows by delivering labware arranged exactly as your process requires. Containers can be sequenced, grouped, aligned by barcode order, or packaged into application-specific sets. This reduces setup time, minimizes sorting errors, and supports predictable movement through automation, screening platforms, or multi-step protocols.

Cleanroom production supports applications that benefit from controlled handling conditions, such as sequencing, cell-based studies, or contamination-sensitive assays. When needed, labware can be prepared in a Class 7 environment using RNase-free, DNase-free, and low-biocontamination practices. This option helps maintain environmental integrity for specialized workflows.

Procurement streamlines your operations by sourcing your exact tubes, vials, plates, or labware. Labware is received, inspected, prepared, marked, and packaged before shipment, removing the need for separate purchasing, transfers, or back-and-forth logistics. This reduces lead times, simplifies coordination across teams, and ensures every unit arrives ready for immediate use.

Share your requirements to receive tailored recommendations for barcoding, weighing, sorting, cleanroom preparation, and workflow-ready labware solutions.

Direct marking methods create permanent identification on labware using technologies engineered for extreme durability. Cured inks, fused inks, ceramic-baked labels, and precision laser etching support high-resolution barcodes and text that withstand solvents, heat, cryogenic storage, and repeated handling. These options offer long-term stability for workflows where adhesive labels may not meet performance or longevity requirements.

Ceramic marking provides a permanent, robust solution for labeling labware that must endure extreme conditions.

These markings are fused to the labware surface, offering exceptional resistance to high temperatures, aggressive chemicals, and mechanical wear.

Ideal for applications requiring the highest levels of durability and longevity, ensuring your vials remain clearly identified throughout its lifespan.

Cured ink marking offers unmatched durability and resilience, making it ideal for demanding lab environments.

This technology provides high-quality, near-permanent markings that resist fading, chemicals, and abrasions.

Perfect for labware subjected to harsh cleaning processes and frequent handling, cured ink marking is a versatile and efficient solutions to ensure your labels remain legible and reliable over time.

Laser marking delivers precision and permanence, creating detailed and highly resistant labels on labware.

This advanced technology uses focused laser beams to etch markings directly onto the surface, ensuring they are impervious to wear and environmental factors.

Laser marking is perfect for high-use labware, providing sharp, clear, and enduring labels that withstand the rigors of daily lab operations.

Yes

No

Sometimes

No

Yes

Yes

Sometimes

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Sometimes

Yes

Yes

Yes

Sometimes

Yes

Yes

Yes

“Computype consistently provides the best labeling solutions for us because they took the time to learn our applications. We don’t have to worry about things like labels, barcodes, container sourcing or weight, because Computype does all that for us.”

read full case study >

Labware Prep™ Services support extensive customization, allowing each container to carry the exact information your workflow requires. Options include custom barcodes, sequential IDs, text, logos, grad lines, and color elements applied directly to the labware. These tailored markings help maintain consistent identification across tubes, vials, plates, and specialty containers, supporting traceability in both routine and highly specialized laboratory environments.

Customize barcodes, Data Matrix codes, and sequential identifiers to match LIMS requirements, automation workflows, or inventory programs, ensuring consistent tracking across tubes, vials, plates, and specialty labware.

Add custom text, logos, grad lines, or color elements directly to labware for clearer identification, improved sorting, and standardized visual cues across shared or high-throughput laboratory workflows.

Choose marking formats tailored to your process, including cap markings, sidewall imaging, bottom-read codes, or multi-surface identification that supports specialized storage, handling, or automation requirements.

Tubes marked with ascending or study-specific ID sequences simplify field collection, aliquoting, and downstream sample reconciliation by eliminating manual numbering.

Directly marked caps improve readability in crowded racks where sidewall labels are blocked, making it easier to confirm identities during sorting, pipetting, or manual verification.

Plates printed with bottom-facing Data Matrix codes support high-throughput imaging, optical assays, and automated plate readers that require unobstructed scan paths.

Vials or tubes marked with precise grad lines support workflows requiring consistent fill levels, such as media preparation, aliquoting steps, or QC sample standardization.

These pre-barcoded vial kits represent a small selection of the ready-to-use labware available through Labware Prep™ Services. While most programs are fully customized to each laboratory’s workflow, these kits offer a convenient option for teams needing consistent, pre-marked vials without a bespoke setup. Each kit supports accurate identification, stable imaging, and efficient sample handling from the moment it arrives.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields