Designed to withstand the high temperatures and harsh chemicals used in PCB production, these labels provide reliable performance in demanding environments.

By integrating high-performance labels into your manufacturing workflow, you can enhance quality control and streamline production.

PCB labels identify consumer devices, automotive electronics, aerospace controls, and medical equipment, ensuring traceability from prototype through mass production in high-stakes industries.

Labels remain readable even on miniature components, helping engineers, assemblers, and quality teams quickly verify placement, connections, and serial data across production lines.

Traceability supports recalls, warranty validation, and ongoing service by linking each PCB to batch records, design revisions, and compliance documentation.

Blank labels are compatible with in-house thermal transfer or laser printers, enabling fast turnaround for variable data, serialization, and prototyping. They support high-mix or low-volume workflows effectively.

Pre-printed PCB labels provide reliable durability with high-resolution print, ensuring compliance and fast application. Ideal for high-volume manufacturing requiring consistent quality and reduced in-line printing steps.

Partially pre-printed labels combine static templates with variable in-house printing, balancing compliance and workflow efficiency. Perfect for adding serials, dates, or barcodes to a durable base design.

Our PCB labels are engineered to withstand the challenging conditions of electronic manufacturing, ensuring consistent performance in the most demanding processes. These labels feature a white gloss modified polyimide face stock paired with a permanent acrylic solvent adhesive, providing exceptional durability and adhesion.

High-heat labels perform up to 1000°F

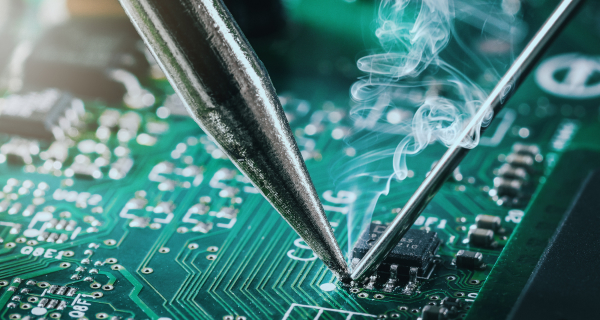

Our labels are engineered for top-side applications, resisting smearing and damage during reflow and wave soldering processes. They offer reliable traceability and identification for various PCB manufacturing needs.

These labels are fully RoHS 2011-65-EU compliant, ensuring they meet stringent environmental and safety standards. This compliance guarantees that the materials used in the labels do not contain hazardous substances, making them safe for use in all electronic components. Our labels provide peace of mind, knowing they adhere to global regulations while maintaining exceptional performance.

Polyimide is the dominant face stock for PCB labels, valued for high dimensional stability at reflow soldering temperatures. Polyester may suit less demanding applications where moderate heat resistance suffices. Both materials support sharp print resolution, barcodes, and graphics. Face stock choice depends on the manufacturing process, balancing heat endurance, abrasion resistance, and clarity for compliance and traceability.

High-performance acrylic adhesives ensure PCB labels remain intact during solder reflow, wave soldering, or conformal coating processes. These adhesives withstand elevated temperatures without degrading and bond securely to board surfaces or components. Clean removability may be an option in specific cases. Adhesive selection balances peel strength, heat resistance, and chemical durability to meet production requirements without compromising board integrity.

Topcoats can enhance print anchorage for on-demand printing, ensuring barcodes and graphics resist abrasion or smudging. Laminates add further protection against physical damage or harsh cleaning processes, though they are generally more practical for pre-printed labels. By applying coatings or laminates, manufacturers improve print quality, extend image life, and safeguard compliance information under demanding production conditions.

Resin ribbons are commonly paired with blank or partially pre-printed labels for strong adhesion and resistance to heat and chemicals. Pre-printed options may incorporate flexographic or UV-cured inks to achieve durable, high-resolution graphics, including full-color templates. Combining durable ribbons with advanced print technologies ensures variable and static data both remain readable throughout assembly, testing, and end use.

PCB labels are available in extremely small sizes for individual components or larger formats for board-level tracking. Shapes can include rectangles, squares, or custom die-cuts for tight fits. Precision die-cutting ensures labels fit pads, connectors, or component bodies without interfering with soldering or functionality. Flexibility in dimensions supports traceability for both prototypes and mass production.

PCB labels often support standards such as UL 969 for marking durability and IPC guidelines for traceability. Pre-printed formats can help streamline compliance by ensuring consistent formatting of mandatory information. RoHS and REACH compliance is also vital to avoid restricted substances. Labels must meet both performance standards and environmental regulations to ensure products are legally marketable worldwide.

Labels endure high temperatures during multiple solder reflow passes, retaining image clarity and adhesion across the most demanding PCB assembly processes.

Labels withstand exposure to flux removers, solvents, and alcohol-based cleaners, ensuring reliable traceability throughout post-solder cleaning and inspection workflows.

Labels maintain strong adhesion even on very small PCB areas, ensuring identification remains intact without interfering with function or assembly precision.

Barcodes and labels on printed circuit boards (PCBs) are vital for tracking, inventory management, and quality control throughout the manufacturing process. These labels must be durable enough to maintain legibility despite exposure to high heat, chemicals, and handling during assembly.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields