Maintain clear, reliable identification through every sterilization cycle. These label constructions are engineered to hold strong and stay legible through gamma irradiation, heat, and chemical exposure. From pharmaceutical packaging to surgical tools and labware, each label is designed to meet the demands of your process. Support traceability and compliance with materials that perform where others fail.

Labels that fail during sterilization can compromise traceability, regulatory compliance, and product safety. These label constructions are built to endure sterilization processes without losing adhesion, distorting, or fading. Whether exposed to radiation, steam, heat, or chemical sterilants, the right materials protect your identification through every cycle.

In sterilized environments, labeling supports critical functions like traceability, inventory control, and compliance. Label failure can result in lost data, delayed procedures, or compromised product integrity. Materials, adhesives, and printed information must remain stable throughout the entire sterilization cycle.

Gamma irradiation penetrates packaging to achieve sterilization without high heat or moisture.

Radiation may embrittle films, fade ink, or weaken adhesives if labels are not radiation-stable.

Durable constructions retain clarity, adhesion, and compliance after gamma exposure.

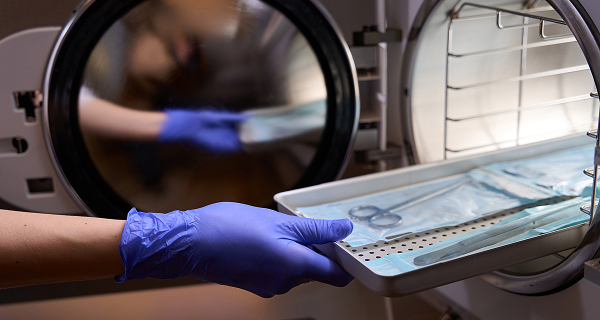

Steam cycles combine high temperatures and moisture to sterilize instruments and labware effectively.

Labels must resist adhesive softening, shrinkage, and ink smudging under saturated steam conditions.

Autoclave-compatible constructions maintain clarity and adhesion through repeated sterilization cycles.

Bleach, ethanol, and peracetic acid are common solutions for cleaning labware and equipment surfaces.

Repeated chemical contact can lift labels or smear identification if materials are not compatible.

Resistant labels maintain legibility and adhesion despite aggressive cleaning protocols and solvents.

Oven sterilization typically reaches 160 to 180 °C for extended durations without moisture present.

Labels endure prolonged heat exposure that can distort films or degrade adhesive performance.

High-temperature materials like polyimide help labels stay legible and bonded after heat treatment.

Ethylene oxide offers sterilization for plastics and electronics requiring gentle, low-temperature processes.

Exposure to EtO gas can soften adhesives or blur printed information if labels lack chemical resistance.

Specialty label materials preserve legibility and adhesion throughout gas sterilization cycles.

Request samples to test durable labeling solutions engineered to endure sterilization, ensuring reliable identification through every critical process.

Sterilization challenges both the physical durability of the label and the chemical stability of its components. Heat, radiation, and chemical exposure can weaken adhesives, distort face stocks, or degrade printed images if materials aren’t properly selected. Choosing the right combination of face stock, adhesive, coating, and print method is critical for maintaining reliable identification through the entire sterilization process.

Thermal transfer label systems with resin ribbons offer good scuff resistance, ideal for workflows where labels may be handled, stacked, or contacted during use.

Choose high-durability, abrasion-resistant labels with pre-printed graphics and barcodes that resist rubbing, scraping, and handling over time—even under repeated use or friction.

Pre-marked labware offers exceptional print permanence, ideal when labels face friction or repeated contact—plus optional services like kitting, sorting, or custom layout.

Thermal transfer and pre-printed images remain crisp and scannable even after repeated exposure to steam, pressure, and moisture.

Specialty adhesives maintain a firm, consistent hold across sterilization cycles, resisting edge lift, flagging, and adhesive failure on curved surfaces.

Face stocks and adhesives resist condensation, sterilant exposure, and chemical disinfectants used in cleanrooms and autoclave prep stations.

We select from high-performance face stocks like polyester, polypropylene, and polyimide, paired with heat- and moisture-resistant adhesives. Every label is constructed with sterilization in mind, including optional pre-coats for printability and topcoats or laminates for protection. Each component supports durability through autoclaving, EtO gas, and chemical sterilants.

Labels are exposed to autoclave steam, ethylene oxide gas, dry heat, and gamma radiation to simulate real sterilization protocols. We validate adhesion, print durability, and material performance before and after exposure. Tests are designed to ensure critical information remains intact and legible across sterilization cycles, with additional resistance testing available upon request.

We support thermal transfer printing with resin ribbons and help match labels to your printer, ribbon, and sterilization workflow. Whether printing trays, tubes, or tools in-lab or integrating with print-and-apply systems, we ensure materials are compatible with your hardware and sterilization process.

Pre-printed labels offer long-lasting image durability and design precision using digital and flexographic printing. We apply coatings and UV-cured inks to improve heat and chemical resistance. Serialized or matched sets are produced with strict sequence control for use in trays, kits, and sterile workflows.

We convert labels in rolls, sheets, or custom formats with die-cut shapes, liner types, and edge profiles tailored to sterilized workflows. These details support accurate placement, clean removal, and reliable adhesion on instruments, trays, and other curved or textured surfaces.

Sterilization-safe labels aren’t just about materials—they’re about how those materials are engineered into a usable form. Our in-house finishing and converting capabilities allow us to build label constructions that suit your sterilization workflow from the ground up. That includes die-cutting custom shapes to fit challenging surfaces, manufacturing labels in rolls, sheets, or fanfold formats, and managing liner types to support manual or automated application.

Sterilization-safe labels are more than a material choice—they’re an engineered solution. We design, test, and convert labels to perform through repeated exposure to heat, pressure, and harsh conditions. From adhesive chemistry to print durability, every element is selected for real-world performance. This is where construction, coating, and converting expertise all come together.

Our labels are built to perform where others fail—from autoclaves to chemical exposure to cold-to-hot transitions and more.

We verify image clarity, adhesive performance, barcode readability, and sequencing to ensure consistent, high-performing results.

We help you choose the right face stock, adhesive, and finish based on your surfaces, sterilization method, and labeling goals.

Not all labels are built the same. Share a few details about your product or environment, and we’ll recommend a label designed to stick, stay readable, and hold up under pressure.

From autoclaves to chemical baths, your sterilization process puts materials to the test. These labels are engineered to stay legible and firmly attached through repeated exposure to high heat, pressure, and moisture. Whether you print them in-house or order them pre-printed, they’re built to perform in critical environments.

Sterilization methods place intense demands on label materials, adhesives, and print surfaces. From radiation exposure to high heat and chemical contact, each process requires specific resistance properties to ensure label integrity. These solutions are designed for compatibility across a range of sterilization techniques and industries.

Autoclave tray and instrument labels

Cryo-to-autoclave tube labels

Sterile glassware and container labels

Pre-printed barcode and tracking labels

Labels must survive high heat, pressure, and handling—often over multiple sterilization cycles—without lifting or fading.

Cryo-to-autoclave workflows require labels that resist both extreme cold and high-temperature sterilization after sample prep.

Reusable tools require small, durable labels that stay readable after harsh cleaning and sterilization in surgical settings.

Labels must survive high heat, pressure, and handling—often over multiple sterilization cycles—without lifting or fading.

Cryo-to-autoclave workflows require labels that resist both extreme cold and high-temperature sterilization after sample prep.

Reusable tools require small, durable labels that stay readable after harsh cleaning and sterilization in surgical settings.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields