Thermal transfer labels deliver unmatched durability for demanding environments, from industrial warehouses to laboratory freezers. With the right combination of face stock, adhesive, and ribbon, these labels stay legible through heat, cold, abrasion, and chemical exposure. We specialize in engineering label solutions that outperform the rest — built for your conditions, your printer, and your industry.

Thermal transfer label construction determines how well labels perform under heat, bond with ribbons, and accept printed images. The right material balance ensures consistent print feed, clean release characteristics, and durable results through demanding conditions. Key performance factors include the label’s heat response, print surface, and overall material compatibility—each influencing print quality, reliability, and long-term adhesion.

Durable thermal transfer labels use heat-stable polyester, polypropylene, or polyethylene face stocks combined with carefully matched ribbons to achieve lasting print performance. Compatibility between ribbon and face stock ensures image stability under heat, abrasion, or solvent exposure. These labels are ideal for on-demand printing in warehouses, laboratories, and manufacturing environments that demand longevity and reliability.

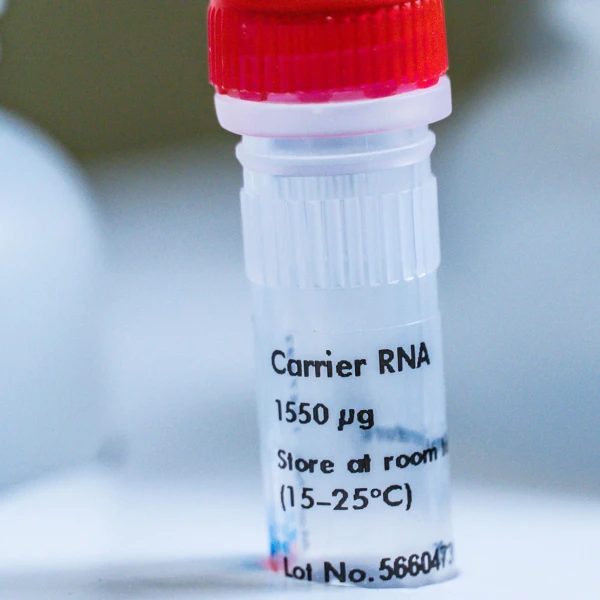

Self-laminating thermal transfer labels combine a printable area with a transparent laminate overlay that protects the print surface once applied. The laminate shields against abrasion, solvents, and moisture, making them ideal for laboratory and industrial environments. Variations include wrap-around tube labels and fold-over formats, each designed to maintain barcode readability in demanding workflows.

Print-and-apply thermal transfer labels are constructed for controlled stiffness, exact liner release, and adhesive flow that aligns with applicator mechanics. These features allow seamless transfer from printer to product without jamming or misplacement. Engineering must balance print quality, feed consistency, and tack level to match the printer’s pressure and speed, ensuring smooth operation at high throughput.

Synthetic face stocks such as polyester, polypropylene, and polyimide provide heat stability, clarity, and ribbon compatibility for precise thermal transfer printing.

Acrylic and rubber adhesives provide the necessary tack, shear, and temperature tolerance to maintain adhesion over time.

Balanced liner stiffness and release properties ensure clean separation, consistent feed, and stable performance during printing and application.

Label materials must react evenly to printhead heat to ensure smooth ink transfer and consistent print density. Stable films prevent distortion during high-temperature printing, maintaining accuracy in both text and barcode imaging.

The label’s topcoat and face stock influence how effectively the ribbon transfers ink, affecting color density, sharpness, and scannability. A smooth, receptive surface enables consistent imaging across a variety of printers and environments.

Durable label construction depends on stable materials that maintain shape, adhesion, and legibility through heat, handling, and environmental stress. Dimensional consistency ensures smooth printer performance.

Thermal transfer ribbons play a critical role in producing crisp, durable images, and label construction directly affects how well those ribbons perform. The right balance of face stock, coatings, and heat response ensures smooth print feed, clean ribbon release, and reliable image transfer. Material compatibility between labels and thermal transfer ribbons ultimately determines print quality, longevity, and performance in demanding conditions.

Thermal transfer ribbons rely on precise ink formulations engineered for controlled melting, transfer, and adhesion. The composition of wax, resin, or hybrid materials determines print quality, barcode readability, and overall print durability. Optimized ink layers deliver dense, high-contrast images that remain legible and resistant to abrasion, smudging, and surface friction throughout a label’s life cycle.

Print durability depends on matching each ribbon to the label substrate. Coated synthetics, polyester, and polypropylene face stocks require ribbons with compatible energy levels and melt characteristics. Proper ribbon-to-substrate pairing ensures crisp image transfer, stable adhesion, and resistance to peeling or fading, maintaining consistent print quality through production runs and variable environmental conditions.

Durable thermal transfer ribbons protect printed data against heat, chemicals, and moisture. Resin-based formulations and specialized backcoats enhance longevity in harsh environments, ensuring barcode and text readability remain intact through handling, sterilization, or cleaning. Environmental resistance is critical for long-term identification in laboratory, industrial, and logistics applications requiring dependable, permanent image durability.

Wax ribbons are the most economical thermal transfer option, using a softer ink that melts easily at lower heat settings. They’re suitable for coated paper labels and short-term applications where durability isn’t critical.

Because the wax layer sits on the surface rather than fusing deeply, it’s more prone to scratching, smudging, and fading over time. These ribbons are best used in controlled indoor environments with minimal handling or exposure. While they deliver sharp print quality at high speed, they cannot withstand heat, chemicals, or abrasion—making them unsuitable for most industrial or laboratory labeling needs.

Wax-resin ribbons provide a balanced combination of print quality and moderate durability. The blended formulation bonds securely to smooth or semi-smooth materials, producing crisp, smudge-resistant images at medium print energies.

They perform well on coated paper and synthetic materials such as polypropylene and polyester. This makes them a reliable choice for inventory management, product identification, and laboratory labeling where moderate resistance to moisture and abrasion is needed. Wax-resin ribbons serve as an excellent midpoint between wax and resin, offering durability and versatility without requiring the high heat and slower print speeds of full resin ribbons.

Resin ribbons offer the highest print durability available in thermal transfer printing. Their hard, heat-activated formulation chemically bonds to the label surface, creating a dense image that resists solvents, abrasion, and extreme temperatures.

They are engineered for synthetic label materials like polyester, polypropylene, and polyimide—substrates that maintain stability under heat and stress. Resin ribbons are ideal for laboratory sample tracking, asset labeling, circuit board marking, and any application requiring permanent readability. Because resin inks demand greater print energy, print speed and heat must be properly adjusted for full transfer. When paired correctly, resin ribbons deliver unmatched performance in demanding industrial and scientific environments.

Color ribbons extend thermal transfer printing beyond black, offering durable colored inks that add visual clarity and impact. Available in standard and custom hues, they enhance hazard communication, product identification, and brand recognition.

These ribbons use pigment-rich formulations that provide opacity and lightfastness, ensuring color stability over time. When paired with compatible synthetic label materials, color ribbons perform with the same chemical and abrasion resistance as standard resin types. They can also integrate into dual-color printing workflows or supplement pre-printed labels for efficient hybrid production. Color ribbons are a versatile solution for facilities that rely on both durability and clear color differentiation in their labeling systems.

Thermal transfer ribbon dimensions must match the label width and printer design. The ribbon should fully cover the label area and slightly exceed the print width to protect the printhead edge. Length affects the number of prints per roll and changeover frequency. Matching these specifications ensures even image transfer, prevents residue buildup, and reduces printhead wear during continuous thermal transfer printing.

Thermal transfer ribbons are wound with the ink layer facing either inward (CSI) or outward (CSO). Printers are designed for one or the other, so correct orientation is essential for proper image transfer. Core size also matters—most desktop printers use 0.5-inch cores, while industrial models use 1-inch. Incorrect winding or core size can cause feeding errors and tension issues.

Ribbon formulations must match the printer’s printhead technology—either flathead or near-edge. Flathead printers use longer dwell times, while near-edge printers require faster ink release at higher temperatures. Each ribbon has a recommended print energy window to achieve optimal transfer density and adhesion. Proper matching prevents image voids, smudging, or excessive printhead wear.

Ribbon coating side indicates which surface carries the ink. CSI ribbons have ink facing inward toward the core, while CSO ribbons face outward. A simple “tape test” can confirm the orientation if unknown. Using the wrong coating side will prevent ink transfer entirely, so verifying this spec before installation ensures successful printing and clean imaging.

Most thermal transfer ribbons include a backcoat layer that reduces static and friction between the ribbon and printhead. High-quality backcoats improve heat transfer efficiency, minimize debris buildup, and extend printhead life. Inferior or uncoated ribbons can increase static discharge and wear, leading to streaking or early printhead failure. Selecting ribbons with engineered backcoats maintains print quality and reduces maintenance costs.

Some assume the face stock drives durability, but in thermal transfer, the ribbon does the heavy lifting. Without a laminate or overcoat, the printed image is exposed — and whether it resists abrasion, solvents, or heat depends entirely on the ribbon.

Thermal transfer printers create durable, high-resolution labels by using heat to transfer ink from a ribbon to the label surface. Selecting the right printer ensures print quality, efficiency, and compatibility with your chosen labels and ribbons. Industrial, desktop, and printer-applicator models each serve unique operational needs, from high-volume manufacturing to precision labeling automation.

Industrial thermal transfer printers are engineered for reliability and speed. They handle larger label rolls, wider media widths, and extended print runs with minimal maintenance. Designed for rugged environments, they deliver consistent print density under continuous use. Typical applications include product identification, shipping labels, and compliance labeling in warehouses or industrial settings.

Desktop thermal transfer printers provide professional-grade print quality in a small footprint. Ideal for labeling tasks that require clarity and durability without industrial throughput, they balance ease of use with precise results. Commonly used in laboratories, healthcare facilities, and office environments, these models are compatible with a wide range of ribbons and label materials.

Printer-applicators integrate directly into production or packaging lines, applying freshly printed labels to products, cartons, or pallets. They eliminate manual handling, improving consistency and throughput in industrial labeling workflows. Ideal for facilities that demand high-volume traceability and efficiency, these systems can be customized for side, top, or corner application positions.

Proper label caliper, liner stiffness, and release characteristics ensure smooth media movement, reducing misfeeds and preserving printhead alignment during extended printing cycles.

Labels engineered with clean liners, anti-static coatings, and compatible ribbons reduce debris, friction, and abrasion that can shorten printhead lifespan.

Label face stocks and ribbon formulations must align for optimal heat response, image transfer, and durability under the printer’s specific energy settings.

Print-and-apply systems require precise label release force, material stiffness, and adhesive flow to ensure consistent pickup, transfer, and placement on moving products.

Thermal transfer label kits simplify selection by bundling compatible labels and ribbons, reducing risk of print failure or excessive printer wear.

With decades of experience in thermal transfer printing, we provide expert support to ensure your systems operate seamlessly. Whether you’re starting from scratch or upgrading existing equipment, our guidance ensures you achieve efficient, high-quality results.

Not all labels are built the same. Share a few details about your product or environment, and we’ll recommend a label designed to stick, stay readable, and hold up under pressure.

Thermal transfer label kits pair engineered materials with thermal transfer ribbons to deliver consistent, durable imaging across demanding lab and industrial workflows. Each construction is designed for optimal heat response, smooth print feed, and reliable ribbon bonding. With application-specific formats—from cryogenic samples to microplate identification—these thermal transfer label kits ensure compatibility, print quality, and long-term performance with standard thermal transfer printers.

Showing 1–9 of 44 results

Thermal transfer labeling delivers long-lasting, high-resolution identification across harsh environments. This FAQ covers the essentials of how thermal transfer printing works, the importance of ribbons and materials, and how to ensure lasting barcode performance, print quality, and durability for laboratory, industrial, and manufacturing applications.

Thermal transfer printing uses heat to permanently fuse ink from a ribbon onto a label surface. A precision printhead applies heat in tiny, controlled dots that melt and transfer the ribbon’s ink onto the label material. Each dot forms part of a barcode, character, or graphic, producing crisp, high-contrast images with excellent edge definition. The result is a printed image that won’t fade, smudge, or degrade over time. Because the ink layer bonds directly to the face stock, the print resists exposure to chemicals, abrasion, and temperature extremes. The method supports a wide range of materials—paper, polypropylene, polyester, and polyimide—and resolutions up to 600 dpi for dense or miniature barcodes used in laboratory and industrial identification.

Thermal transfer printing creates durable, high-resolution images using a separate ink ribbon, while direct thermal printing burns an image directly into heat-sensitive paper. Direct thermal labels darken when exposed to heat or light and are designed for short-term use such as shipping or receipts. Thermal transfer labels, by contrast, are built for longevity. The ribbon acts as both the ink source and a buffer that protects the printhead from wear, extending printer life and ensuring stable output quality. Because the printed image becomes part of the label surface, it remains legible through handling, cleaning, sterilization, or outdoor exposure. For laboratories, manufacturing lines, and any application requiring traceability or regulatory compliance, thermal transfer printing is the only reliable choice.

Materials that can withstand consistent heat and allow clean ink transfer perform best in thermal transfer printing. Paper provides economical, high-contrast printing for controlled indoor use. Polypropylene offers flexibility, good moisture resistance, and smooth surfaces for consistent barcode edges. Polyethylene adds stretch and conformability for curved or squeezable packaging. Polyester delivers excellent dimensional stability, heat resistance, and chemical durability, while polyimide handles extreme processes like solder reflow or autoclave sterilization. Each substrate interacts differently with heat and ribbon chemistry—rough, porous papers require lower temperatures, while dense synthetics need higher energy for full ink anchoring. Selecting the right material ensures strong image transfer, optimized ribbon performance, and long-term barcode readability under environmental stress.

Selecting the correct ribbon is critical to print durability and image stability. Wax ribbons are formulated primarily with wax compounds that melt at low temperatures and bond well to paper labels. They produce dark, clean prints for short-term indoor use but offer limited resistance to abrasion or chemicals. Wax-resin ribbons combine wax’s printability with resin’s toughness, providing improved scratch, smear, and moderate solvent resistance—an ideal middle ground for coated papers and many synthetics. Resin ribbons deliver the highest durability; their inks melt at higher temperatures and chemically bond to films such as polyester, polypropylene, polyethylene, and polyimide. These ribbons withstand autoclaves, extreme cold, oils, and solvents. Advanced formulations can include additives or crosslinking agents to improve adhesion, heat stability, or chemical resistance. Because thermal transfer performance depends on the interaction between ribbon chemistry and label surface energy, we pre-match all ribbons to specific label constructions—so you never need to source or test ribbons separately.

Thermal transfer labels achieve exceptional durability when the right materials and ribbons are combined. Resin ribbons create dense, fused images that resist abrasion, solvents, and temperatures from deep-freeze to high heat, depending on the label construction. Paired with polyester or polyimide face stocks, they endure autoclaves, chemical cleaning, and outdoor exposure without loss of readability. Self-laminating thermal transfer labels, such as wrap-around tube designs, add a clear overlaminate that seals the printed data, forming a physical barrier against moisture and abrasion. When backed by high-performance adhesives, these labels remain intact through cryogenic storage, heat sterilization, or extended UV exposure. Durability ultimately depends on image chemistry and surface bonding—the better the match, the longer the identification lasts.

Print speed and heat directly determine image density, sharpness, and adhesion. Too little heat yields faint or incomplete barcodes; too much heat softens edges, causes smudging, and accelerates printhead wear. Slower speeds increase dwell time—improving ink transfer on dense synthetics—while higher speeds require higher energy or more sensitive ribbons. Resin ribbons, which most industrial and laboratory users rely on, demand the greatest energy and benefit from reduced print speeds to ensure full ink fusion with the substrate. Insufficient heat or excessive speed with resin ribbons can cause weak anchoring or glossy, uneven patches. Optimal performance comes from fine-tuning print speed and darkness together until the image appears uniform and scratch-resistant. Regularly cleaning the printhead and rollers prevents debris that can interfere with dot firing and ensures consistent, high-resolution output across long production runs.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields