Ensure accuracy and consistency in every step. From print-ready label kits to fully marked labware, every option is built for clarity and durability.

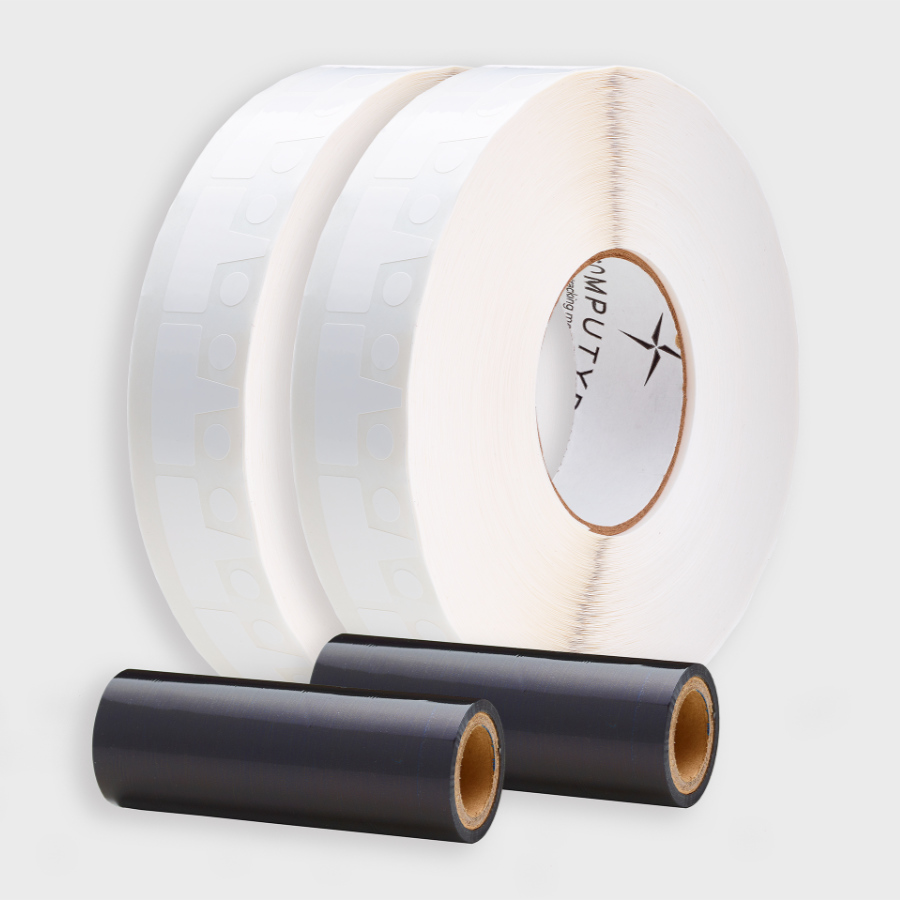

Blank labels and ribbons for thermal transfer printing

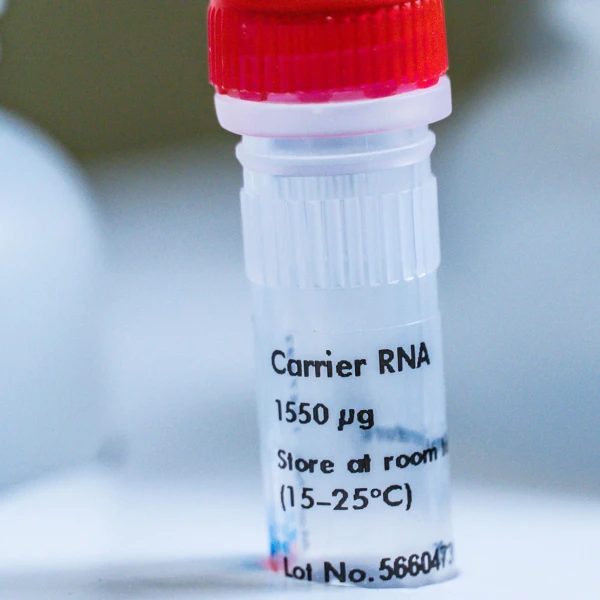

Pre-marked tubes and vials with barcodes or graphics

Automated print-and-apply systems for tube labeling

Explore pressure-sensitive labels, custom markings, and automation-ready solutions. Whatever your workflow, we’ll help you label with confidence.

Different labs require different tube labeling strategies. Choose from blank labels for in-lab printing, pre-printed labels with your data, or fully pre-marked tubes ready to use. Each option supports traceability, speed, and labeling precision, just in different ways.

Print what you need, when you need it. Compatible with thermal transfer ribbons and lab printers, these labels offer flexibility for labs that manage variable data, evolving workflows, or on-demand identification.

Barcodes, text, and color are printed in advance using high-resolution technologies like digital and flexographic. Pre-printed labels save time, reduce print errors, and ensure a consistent, scannable image across all your tubes.

Ideal for high-throughput or regulated labs, these tubes arrive ready to use with permanent barcodes or human-readable IDs already in place. Skip the labeling step entirely and reduce the risk of label failure.

Label microcentrifuge tubes, cryovials, blood tubes, chromatography vials, ampoules, syringes, and more.

Add 2D barcodes, ID sequences, or color markers to caps and bottoms for fast, space-efficient identification.

Adheres securely to PCR strips, microvolume tubes, and other labware with tight curves or minimal surface area.

Withstand cryogenic storage, centrifugation, autoclaves, and chemical exposures without label failure.

Stay scannable and secure during freezing, thawing, and lab processing.

Ensure long-term readability and adhesion under intense and variable lab conditions.

Designed for precision placement on uncapped, capped, or filled tubes and vials.

Compatible with vertical applicators that support robotic workflows.

Streamline labeling and reduce manual handling with automated efficiency and repeatable positioning.

Support workflow differentiation using pre-colored or custom-printed tube labels.

Enable faster sorting, scanning, and error reduction in high-volume environments.

Choose from spot color, full color, and color-matched print capabilities for flexible identification.

Support compact formats like Data Matrix, QR, and micro linear barcodes.

Maintain barcode accuracy and readability despite small print areas or curved surfaces.

Ensure clean imaging and precise sequencing for error-free identification across labs and systems.

Support unique label shapes including wrap-around, flag-style, and custom die-cut constructions.

Ensure proper adhesion and readability on curved, conical, or small-diameter tubes and vials.

Label complex labware without compromise using precisely engineered formats tailored to fit and function.

Talk to a labeling expert to find the right tube labeling solution for your tubes, workflow, and lab equipment.

Whether you’re labeling small caps, contoured surfaces, or need full-wrap durability, specialized formats can make the difference. These label constructions are designed to improve adhesion, maximize print space, and ensure readability—even on tubes that are capped, frozen, or uniquely shaped.

Labels remain securely bonded and fully legible during storage in ultra-low freezers, dry ice transport, and vapor-phase liquid nitrogen. Adhesives and face stocks are selected specifically for high-performance at -80°C to -196°C.

Built to withstand harsh exposure to alcohols, DMSO, xylene, and common cleaning agents without fading, smearing, or peeling. Ideal for labs where solvents are part of prep, sterilization, or sample workflows.

Engineered to stay readable through physical stress like vortexing, centrifugation, and repeated gloved handling. Topcoats and laminates protect printed data from smudging, scuffing, and wear in busy lab environments.

Labels are converted to exacting tolerances, including notches, curves, and features designed for automation or specific vial geometries.

We produce extremely small labels for micro formats like PCR strips, caps, and high-density storage vials without compromising durability.

Die-cut labels with matching components—like vial body and cap labels—support linked tracking across multiple surfaces or packaging levels.

Tube and vial labels require flexible face stocks that can conform tightly to curved and small-diameter surfaces without winging or edge lift. Materials include polyethylene, polypropylene, and polyester films — chosen for their balance of durability, flexibility, and printability. Thinner constructions help reduce stiffness under tight mandrel conditions, while specialty coatings on the surface improve image clarity and support high-resolution barcodes. For certain materials, precoats may be added to enhance print receptivity, while optional topcoats improve resistance to handling, abrasion, and chemical exposure.

Adhesives for tubes and vials must bond reliably to both plastic and glass surfaces — including materials like polypropylene, polyethylene, and borosilicate glass. We offer a range of adhesive chemistries, including rubber- and acrylic-based systems. Acrylics are often chosen for cryogenic and high-temperature applications, while rubber adhesives may offer superior initial tack for curved or textured surfaces. Additives such as tackifiers or plasticizers can be included to modify bond strength or flexibility depending on the application. All medical and clinical adhesives are compliant with FDA 21 CFR 175.105 where applicable.

We enhance label performance with optional coatings and laminates tailored to each application. Precoats are sometimes applied to improve ink anchoring and surface tension compatibility with thermal transfer or digital inks. Topcoats can increase resistance to solvents, sterilants, and abrasion. Laminates — including self-laminating designs for tubes — physically protect the printed image by covering it with a transparent film, which is particularly useful in cryo storage or repeated chemical exposure scenarios.

Printed tube and vial labels rely on technologies suited to their environmental demands. Thermal transfer printing with wax/resin or full resin ribbons offers strong chemical and temperature resistance. For pre-printed labels, UV-cured inks provide excellent durability on coated films, and full-color digital and flexographic printing allows for logos, grad lines, color-coding, and fine-resolution elements. Print methods are selected for adhesion to the face stock and compatibility with post-print processing like lamination or sterilization.

Tubes and vials come in an array of configurations — from cylindrical microcentrifuge tubes to broad cryo vials, flat-bottom autosampler vials, or even divisible PCR strips. Label shapes are tailored to each format, with options like wrap-around labels, flag labels, and cap or plug labels. Construction details like tapered edges and controlled stiffness help ensure tight wrapping and resistance to winging, while label size and orientation are optimized for print area, barcode scanning, and automation.

Label components are selected to support regulatory compliance in laboratories and manufacturing environments. Adhesives meet FDA 21 CFR 175.105 where needed for clinical use, and materials can be engineered to comply with RoHS and REACH restrictions on hazardous substances. We also support traceability and data retention standards across controlled environments, ensuring labels stay readable and adhered throughout the lifecycle of the product — from storage to disposal or long-term archiving.

Choose from blank label kits with compatible thermal transfer ribbons, including cryo labels and tube-and-cap sets, or order pre-marked vials with matching caps.

From desktop printers to fully automated systems, these devices support accurate, efficient labeling across a wide range of tubes and vials. Whether you’re printing labels in-house or integrating into a high-throughput robotic workflow, these options offer reliable performance and compatibility with a variety of tube types and sizes.

Compact desktop printers ideal for basic tube label printing with thermal transfer capabilities and flexible media handling options.

Reliable 300 dpi printing in a small footprint, commonly used in laboratories for tube, cap, and vial label production.

Durable, high-precision printers designed for continuous or die-cut tube labels, compatible with curved surfaces and tight mandrels.

Automated vertical tube labeler ideal for integration into robotic workflows. Supports filled, capped, and uncapped tube handling.

Flexible semi-automated labeler for tubes. Foot pedal or button activation simplifies print-and-apply processes in varied lab environments.

Fully automated system for labeling and racking tubes in high-throughput labs. Integrates with scanners, de-cappers, and robotic handlers.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

© Computype 2024

© Computype 2024

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields