Chemical-resistant labels safeguard critical information in environments where standard labels fail. Built with specialized materials, they maintain legibility and adhesion when exposed to solvents, acids, and aggressive cleaners. These durable adhesive labels endure anything from brief splashes to full chemical submersion. Industries like pharmaceuticals, manufacturing, and chemical processing depend on them for safety, traceability, and compliance.

Chemical exposure can quickly degrade a label’s legibility, adhesion, or both. Whether you’re working with aggressive solvents like xylene or handling disinfectants like 70% IPA, label failure isn’t an option. Chemical resistance depends on the right combination of face stock, adhesive, ink, and protective layers—each tailored to the chemicals involved. That’s why material selection and testing are critical to success.

From lab solvents to manufacturing fluids, chemicals threaten label performance at every stage. Choosing the right materials prevents failure under splash, vapor, or wipe-down exposure. These solutions are tested to perform in demanding, real-world environments.

Prevent label lifting or curling

Protect barcodes from smearing

Withstand repeated surface wipe-downs

Survive accidental splashes or spills

Toluene, acetone, and xylene are common in coatings, extractions, and industrial cleaning workflows.

Solvents may splash, soak, or vaporize, degrading labels through chemical softening or edge lifting.

Durable label materials and adhesives are needed to survive prolonged or repeated solvent contact.

Isopropanol, ethanol, and bleach are widely used in labs, clinics, and cleanroom environments.

Frequent wipe-downs can compromise label coatings, printed barcodes, and adhesive bonds.

Chemically resistant label systems preserve legibility through repeated cleaning and sterilization cycles.

Strong acids and bases are used in sample prep, digestion, pH adjustment, and glassware washing.

Labels on containers or work surfaces may be exposed to splashes, spills, or reactive fumes.

Resilient constructions withstand these harsh conditions without delaminating, fading, or smearing.

Oxidizers like nitric acid and peroxides are used in etching, sterilization, and surface cleaning.

These chemicals can react with label components, weakening structure or altering readability.

Chemical-resistant labels maintain performance even under repeated exposure to oxidizing agents.

Grease, silicone oil, and hydraulic fluids are common in automotive, tire, and industrial applications.

Labels exposed to these substances may lose grip, smear, or collect dirt that obstructs scanning.

Engineered adhesives and face stocks provide resistance to fluid penetration and label failure.

Request a sample to see how these chemical-resistant labels hold up under your toughest lab or manufacturing conditions.

Each layer of a chemically resistant label plays a crucial role in ensuring durability. From face stocks to adhesives, every component must be carefully selected to withstand harsh substances. Protective coatings and laminates further enhance the label’s ability to endure aggressive chemical exposure.

When paired with the right ribbon, thermal transfer labels can withstand common solvents and chemicals, offering flexibility for in-house printing with matched printers.

Pre-printed labels with chemical-resistant coatings offer superior durability when exposed to harsh agents, maintaining barcode clarity, text legibility, and adhesive performance.

Pre-marked labware ensures print durability even through repeated chemical exposure—ideal for labs that prioritize cleanliness, traceability, and resistance to solvents.

UV-cured inks and protective coatings prevent smudging or fading when exposed to chemicals like xylene, ethanol, and bleach.

Labels remain secure even after repeated disinfection, spray-downs, or exposure to solvents during cleaning or processing.

For thermal transfer workflows, wraparound and laminate-over labels protect printed areas from exposure to wipes and splashes.

Chemical-resistant labels rely on durable face stocks like polyester and polypropylene, paired with adhesives that resist breakdown when exposed to solvents or reagents. We choose materials that prevent smearing, lifting, or degradation when in contact with substances like xylene, ethanol, or bleach.

We test label performance against aggressive chemicals including solvents, acids, and sterilants using standardized rub and soak methods. From incidental contact to prolonged exposure, we validate print durability, adhesive resistance, and overall label integrity for demanding chemical environments.

Thermal transfer printing with resin ribbons provides superior resistance to chemical smearing. We help you match labels and ribbons to your specific chemical environment, ensuring that print remains legible and adhesion remains stable—even after repeated chemical exposure or wipe-downs.

Digitally and flexographically printed labels can include chemical-resistant inks, cured coatings, and permanent images that withstand repeated cleaning and chemical contact. We maintain tight control over variable data and print durability across millions of labels for regulated and research-driven environments.

Sterilization-safe labeling doesn’t stop with the label itself—it’s about making sure your workflow, print process, and hardware all align. Our label solutions are compatible with a wide range of printing systems, including thermal transfer printers, laser printers, and fully automated label applicators. If you’re printing in-house, we’ll guide you toward face stocks and coatings that match your specific printer model, ribbon type, and print resolution needs.

In labs and cleanrooms where sterilization is required, hardware selection often impacts label durability. For instance, thermal transfer printing combined with resin ribbons offers enhanced chemical and heat resistance—critical for autoclave or chemical sterilant workflows. When automation is part of the process, we ensure label materials meet the physical requirements of robotic handling, high-speed printing, or tight label tolerances. No matter how you’re printing—whether it’s a single workstation or a full-scale automation line—our labels are designed to work with your equipment, not against it.

We convert chemical-resistant labels in rolls, sheets, or multi-label sets with custom die-cuts and formats optimized for your application. From microscope slides to reagent bottles, each construction supports durability, handling, and identification through chemically harsh conditions.

Chemical exposure is one of the fastest ways to degrade a label—but it doesn’t have to be. Our chemical-resistant labels are engineered for long-term adhesion and print clarity, even when exposed to solvents, disinfectants, and reagents. These solutions are commonly used in labs, cleanrooms, pharmaceutical production, and harsh industrial environments.

We match face stocks, adhesives, and inks to the chemicals you use—ensuring durability without guesswork or overengineering.

Our labels are used in pharma, biotech, and diagnostics—industries where chemical exposure is routine and failure is not an option.

We understand how chemical exposure impacts labeling and help customers solve durability issues across diverse workflows and surfaces.

Not all labels are built the same. Share a few details about your product or environment, and we’ll recommend a label designed to stick, stay readable, and hold up under pressure.

Chemical-resistant labels are essential anywhere exposure to solvents or cleaners is routine. Applications span from laboratories and hospitals to heavy industry and electronics. Proper labeling ensures safety, compliance, and traceability even under extreme chemical stress.

Chemical exposure doesn’t happen in a vacuum—it happens during vital work. Label failure can interrupt workflows, compromise samples, or delay production. These applications highlight just how high the stakes can be.

Lab sample identification

Cleanroom inventory labeling

Parts tracking during cleaning

Harsh washdown environments

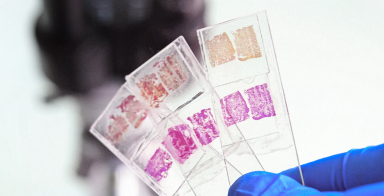

Ensure barcodes remain readable through xylene, alcohol, and heat exposure during slide staining, tissue embedding, and cassette processing.

Label plastic or metal parts exposed to toluene-based cleaners, degreasers, or solvents throughout manufacturing, assembly, or quality control.

Identify circuit boards and electronic parts exposed to MEK during surface prep, cleaning, or rework in electronics manufacturing environments.

Label tubes used with DMSO, ethanol, or acetone in chemical prep, sample storage, or long-term lab workflows.

Label drums and bulk containers exposed to aggressive chemicals during handling, storage, or waste processing in industrial settings.

Label bins and supply containers wiped daily with bleach or peroxide in clinical, diagnostic, or hospital inventory systems.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields