Accelerate drug discovery workflows with labeling solutions designed for compound storage and high-throughput screening. Precise identifiers ensure reliable tracking, protect data integrity, and support scalability. From curated libraries to complex assays, flexible formats integrate seamlessly across evolving research environments. Enable smoother processes by aligning labeling strategies with screening platforms and automated systems.

Drug discovery relies on precise sample management across compound storage, chromatography, and high-throughput assays. Reliable identification safeguards data integrity, reduces relabeling, and supports compliance. With labeling solutions designed for specialized labware and automated workflows, compound libraries, assay plates, and cryo vials remain consistently traceable from early screening through advanced testing.

Engineered recovery vials support compound libraries where every microliter counts, ensuring maximum retrieval without waste.

Specialized coatings and markings provide chemical resistance, serialization, and compatibility with automated handling systems.

Options include blank labels, pre-printed formats, or pre-marked vials designed for efficient storage and reliable downstream access.

Chromatography workflows rely on vials that withstand solvents, pressure, and repetitive instrument handling.

Barcoded and pre-marked options enhance reliability, reducing misidentification during high-throughput assay development and compound testing.

Labels and ribbons are validated for solvent exposure, ensuring barcode durability across repeated injections and extended analytical runs.

Microplates drive high-throughput screening campaigns, requiring labels that maintain adhesion through robotic cycles and solvent exposure.

Available solutions include blank plate labels, pre-printed barcodes, or fully pre-marked plate kits.

Options accommodate serialization, sequences, and color-coded formats, supporting streamlined integration into automated data-driven workflows.

Cryo vials protect compound and biologic samples under liquid nitrogen and ultra-low storage conditions.

Labels must resist brittleness, ice formation, and solvent rinses, ensuring consistent tracking across cycles.

Available options include cryo-rated adhesives, wrap-around formats, and pre-marked vials with serialized identifiers for streamlined biobank integration.

Tube racks organize collections efficiently, supporting retrieval and storage across drug discovery pipelines.

Permanent barcodes or durable rack labels improve scanning accuracy during automated or manual access.

Solutions include pre-marked racks, blank labels for in-house printing, or serialized sets aligned with compound tracking systems.

Request a sample to evaluate labeling solutions for compound libraries, chromatography, and cryo storage, ensuring seamless integration into discovery workflows.

Prevent mix-ups with engineered labels that withstand solvents, freeze–thaw cycles, and high-throughput handling, ensuring compound data stays reliable throughout discovery workflows.

Maintain efficiency by using barcodes and adhesives designed for robotic systems, ensuring seamless compatibility with automated handling, plate readers, and liquid handling platforms.

Safeguard stored compounds with durable identifiers, including recovery vials and cryogenic formats, engineered to resist degradation during extended storage and repeated testing cycles.

Drug discovery, compound storage, and screening workflows demand reliable labeling at every step. From cryogenic vials to microplates, flexible solutions ensure clarity, durability, and compatibility. Explore options to order blank labels, ribbons, or pre-barcoded labware, with tailored kits to support any lab’s workflow.

Thermal transfer label kits support variable study identifiers, cage numbers, or tissue sample IDs. Options resist refrigeration, freeze-thaw, or solvent cleaning during in vivo workflows.

Custom pre-printed labels streamline compound library management. Barcodes, custom colors, and chemical-resistant coatings support long-term storage and reliable data retrieval.

Vials and plates arrive pre-marked with durable identifiers. Options include serialized 2D barcodes, tare weights, or chemical-resistant markings for long-term compound storage.

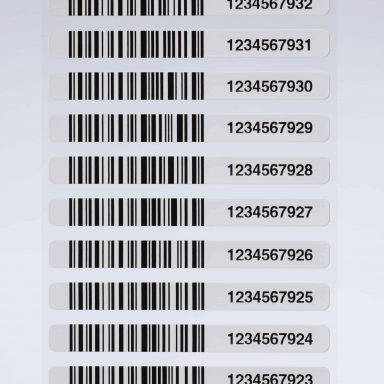

Dense data storage in 2D codes ensures reliable identification in HTS platforms and compound storage libraries, supporting precise sample tracking.

Unique identifiers across multiwell plates or screening sets support automation, prevent collisions, and enhance traceability during assay development.

Labels can display storage temperatures, expiration dates, or assay IDs. These details maintain integrity and prevent misplacement within complex workflows.

For a biobank tasked with collecting over 35 million samples from more than one million participants, reliable tracking was mission-critical. Standard adhesive labels couldn’t keep up — prone to wear, incompatible with some automation platforms, and offering no backup if a code failed.

By shifting to direct-marked 2D barcodes, duplicated with linear and human-readable IDs, every tube now carries built-in redundancy. This triple-assurance approach eliminates labeling failures, ensures compatibility with both modern and legacy instruments, and protects sample integrity for decades. What began as a daunting scale challenge became a system built for speed, certainty, and discovery at the highest level.

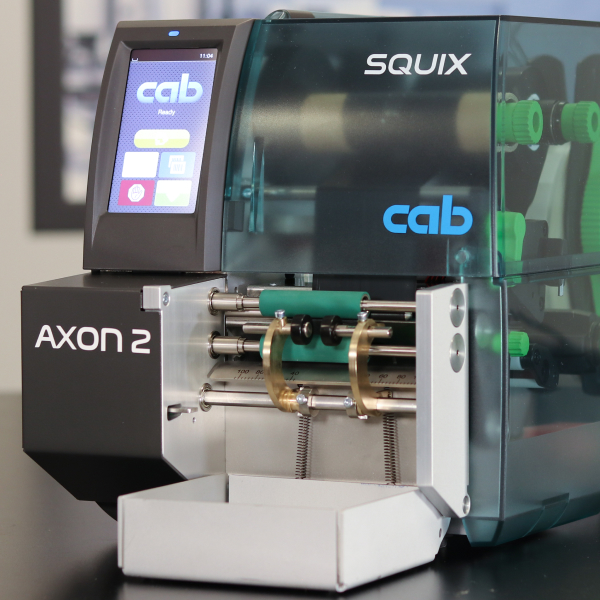

When printing labels in-house, reliable printers and applicators keep workflows running efficiently. Thermal transfer printers produce durable images, while automated applicators ensure precise placement on tubes, vials, or plates. Pairing the right equipment with the right labels supports accuracy, reduces errors, and accelerates drug discovery workflows.

Printing and applying labels in-house requires dependable equipment designed for laboratory demands. Thermal transfer printers deliver crisp, durable barcodes and text for cryogenic, chemical-resistant, and general-use labels. Automated applicators, such as those for tubes or plates, enhance consistency by reducing variability and increasing throughput. Whether labeling high volumes or specialized formats, the right equipment ensures accuracy, speed, and seamless integration into sample processing workflows, while pre-printed labels remain available for labs preferring a ready-to-use solution.

Label constructions built for equipment compatibility

Label design and printing software options

Thermal transfer ribbons matched to materials

Durable imaging for harsh environments

Thermal transfer printers create long-lasting identifiers on blank label kits. Combining precision with durability, they produce clear barcodes and text that withstand demanding environments, including cryogenic storage and chemical exposure.

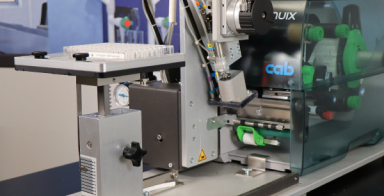

Automated label applicators from providers like cab and Scinomix streamline labeling. Designed for tubes, vials, and plates, these systems improve accuracy, support high-throughput operations, and minimize errors associated with manual labeling.

Fully automated tube labeling system that handles high volumes with precision. Enhances throughput and reduces human error in sample accessioning.

Compact tube labeler designed for lab automation workflows. Supports vertical orientation and robotic handling with precision application.

Automated plate labeling system ensuring consistent barcode placement. Ideal for high-throughput laboratories managing extensive plate libraries.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields