Our customized labels have been developed to survive any condition, stay secured to any surface, and offer perfect clarity every step of the way. With our trusted solutions, tailored to the items you need to track, you can optimize your workflow, reduce waste, and maximize efficiency.

For over 50 years, we’ve been labeling anything our customers bring us. Our labels stick to any surface, withstand any environment, and scan flawlessly, every time. The result – identification that offers perfect clarity and confidence. If there’s a way to label it, we’ll find it.

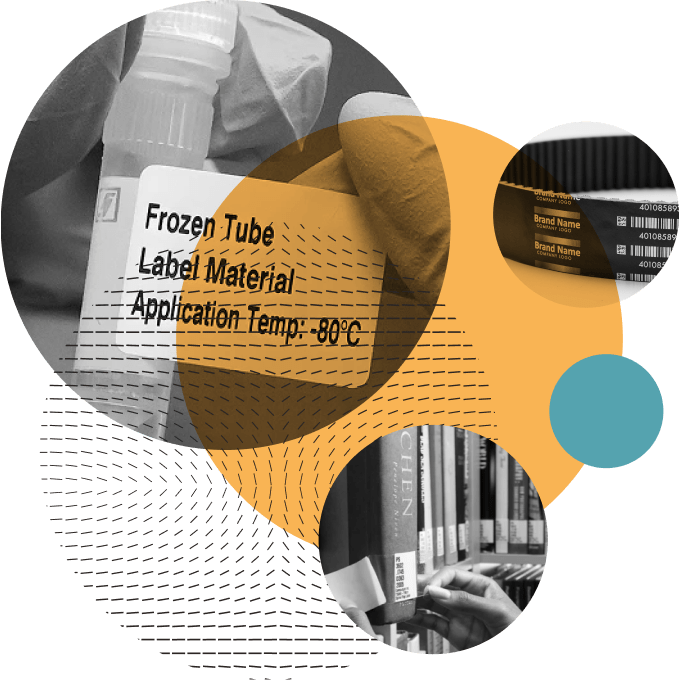

Whether you need printable blank labels or a more complex custom printed set, our labels are engineered to survive the most extreme conditions. Say goodbye to labels that get lost, smudged, or end up unscannable – no matter what, our labels always look like new.

We design, print, and support labeling systems built for accuracy and reliability. From pressure-sensitive to thermal transfer and barcode integration, our engineered labels combine material science and print expertise to meet the highest demands in identification and traceability.

Pressure sensitive labels deliver long-lasting performance through precision-engineered materials and adhesives. Each construction balances strength, flexibility, and compatibility for consistent results across manufacturing, lab, and logistics applications. Designed for both pre-printed and print-on-demand use, these labels maintain durability and legibility in even the toughest environments.

Barcode labels connect your assets to data systems for complete visibility and control. Built for readability and endurance, they perform on small or irregular surfaces, harsh environments, and complex workflows. With expertise in symbology design and material pairing, these labels ensure flawless scanning and data integrity from start to finish.

Thermal transfer labels enable high-quality, on-demand printing with exceptional image durability. Compatible with a wide range of ribbons and printers, these labels deliver consistent results in laboratory, manufacturing, and logistics settings. Available as blank stock or pre-configured kits, they support efficient, flexible labeling without compromising longevity.

Barcode label printers provide precise, reliable printing for durable labeling. Featuring trusted models from cab, TSC, and Zebra, our lineup covers both desktop and industrial needs. Each printer supports thermal transfer technology for superior image quality, extended label life, and efficient operation in high-demand production settings.

Label printing services combine advanced print technologies with specialized finishes to deliver durable, high-performance labels. From flexographic and digital to hybrid printing, each label is optimized for clarity, color accuracy, and endurance. Protective coatings and laminates enhance resistance to chemicals, abrasion, and temperature for unmatched reliability.

Trusted by industries worldwide, our expertly engineered labels ensure reliability, durability, and seamless integration into your workflow.

Withstand cold storage down to -20°C and multiple freeze thaw cycles.

Protect vital information when exposed to solvents, acids, and other chemicals.

Survive conditions and processes using extreme heat and pressure.

Endure the roughest and toughest, high friction environments.

Gamma resistant, UV resistant, microwavable, and radiation resistant.

Withstand extreme temperatures to -196°C, moisture, and flash freezing.

Waterproof, dissolvable or weather-proof.

Labeling glass surfaces introduces unique challenges, including smoothness, non-porosity, and the need for optical clarity. Variations in glass types, such as tempered or borosilicate glass, impact label adhesion and visibility.

Industries like pharmaceuticals, labware, and architecture demand labeling solutions that maintain clarity, withstand temperature changes, and ensure reliable identification.

Labeling metal surfaces presents unique challenges, including oxidation, contamination, and varying finishes like bare, coated, or painted metals. These factors impact label adhesion and durability.

Industries such as automotive, electronics, and aerospace require reliable labeling solutions to ensure proper identification and tracking of metal parts and products.

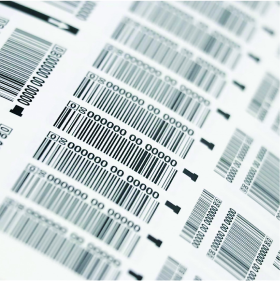

Labeling plastic surfaces involves tackling diverse challenges, such as varying surface energies, textures, and chemical compositions. Different types of plastics, from polyethylene to polycarbonate, affect how well labels adhere and endure over time.

Sectors like packaging, consumer goods, and medical devices require versatile labeling solutions that ensure durability and legibility.

Labeling rubber surfaces presents distinct challenges, including flexibility, elasticity, and exposure to harsh environments. The dynamic nature of rubber, combined with its interaction with oils, chemicals, and high temperatures, demands robust labeling solutions.

Industries such as automotive, industrial manufacturing, and medical devices need labels that can withstand mechanical stress.

Labeling silicone surfaces poses specific challenges due to their low surface energy and high flexibility. Silicone’s resistance to adhesives, combined with its exposure to extreme temperatures and chemical environments, requires advanced labeling solutions.

Applications in medical devices, electronics, and consumer products necessitate labels that securely adhere to silicone.

Get durable labels designed for fabric and textile applications. Choose from blank or pre-printed options that withstand industrial laundering and heat.

Label adhesion is important, but the surface matters too. A label that bonds well to glass might not perform on textured plastics or metal. That’s why it’s essential you choose the right material. Whether smooth, rough, porous, or flexible, our labels securely adhere and stay in place on every surface.

From plastics, metals, and glass to textiles, our labels always bond correctly and resist peeling, bubbling, or slipping.

Our labels provide a strong and lasting hold to smooth, curved, textured and porous surfaces.

Our customized solutions include both permanent, high-bond labels and labels that can be removed without residue.

Need a helping hand? Save time and curb equipment costs by letting us take care of your labeling.

It’s never one-size-fits-all; through bonding our labels to your labware, our innovative marking technologies are tailored to the environment and critical requirements of your process.

Ensure reliable measurements with labware precision-weighed to +/- 0.0002g depending on your label or marking technology.

Marking choice made? From sequential sorting to kitting and branded packaging, we make sure every detail is tailored to your needs.

Our Certified ISO Class 7 cleanroom production facilities meet rigorous standards for contamination control.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields