In the world of laboratory operations, sample identification has long been a topic of both necessity and contention. Laboratories, whether they’re focused on scientific research, healthcare, manufacturing, or any other field, have historically employed a mixed bag of methods to identify and track samples, reagents, assets, and fragments. From handwritten labels in physical notebooks to the ever-reliable Sharpie marker scrawled on labware, these traditional approaches have persisted as the status quo for decades.

However, the landscape of laboratory science is evolving rapidly, and the demands on laboratories to ensure accuracy, traceability, and compliance with strict regulations are higher than ever before. This is where the paradigm shift toward embracing barcode identification solutions becomes not just a choice but a necessity for labs of all sizes and disciplines.

The Challenge of Lab Sample Identification: A Mixed Bag

The challenge that laboratories face today is a complex tapestry woven with threads of tradition, hesitation, and a need for transformation. On one hand, laboratories operate under stringent regulatory environments, which require meticulous record-keeping and traceability. These regulations necessitate accurate identification and tracking of samples and reagents, leaving no room for error or ambiguity.

On the other hand, labs have become comfortable with their well-worn, manual methods. The tactile act of handwriting labels or using markers like Sharpies on labware has become ingrained in the culture of the laboratory. Yet, this very comfort with tradition can breed complacency and limit the potential for efficiency and precision.

The Value of Unique IDs in the Lab: Every Sample, Every Asset

In today’s competitive and data-driven world, the laboratory landscape demands more than just compliance; it craves optimization. The value of unique sample identification lies in its ability to transcend the limitations of manual tracking and open doors to a new realm of possibilities.

Imagine a laboratory where every tube, every plate, every asset, and every fragment possesses a unique identifier—a digital signature, if you will. This identifier becomes the key to unlocking a treasure trove of benefits:

Accuracy: Human errors, such as misread labels or illegible handwriting, become relics of the past. Accuracy in sample identification is assured.

Efficiency: The time spent manually recording data, searching for samples, and deciphering handwritten labels is drastically reduced. Efficiency soars as tasks are streamlined.

Traceability: Laboratories can effortlessly trace the journey of every sample from inception to completion. Audits and compliance requirements are met with ease.

Creating a Digitally Empowered Lab: No Sweat

Labs often hesitate to fully adopt barcode sample identification due to misconceptions. Some believe it’s an unnecessary endeavor, while others consider it a daunting task to implement. However, the reality is that with the right partner and the right approach, the transition to barcode-based sample identification is not only feasible but also incredibly beneficial.

This guide is dedicated to demystifying the world of barcode sample identification in laboratory settings. It’s a roadmap that will guide you through understanding barcodes, selecting the right symbology, designing effective labels, and navigating the regulatory landscape. We will delve into sequence management, implementation strategies, and the importance of training and integration.

The time has come for laboratories to shed the limitations of the past and fully embrace the potential of barcodes. The benefits are clear, the technology is available, and the journey is within reach. Join us on this transformative voyage as we explore the world of barcode sample identification in laboratories, where accuracy, efficiency, and precision become the new norm.

Laboratory Barcode Symbologies

Barcode symbology, often referred to as the barcode type or format, is the underlying language of barcodes. It defines how data is encoded and represented visually within the barcode itself. Each symbology is designed for specific use cases, and choosing the right one is crucial for ensuring effective sample identification and tracking.

Common Barcode Symbologies in Labs

Laboratories encounter a variety of barcode symbologies, each designed to meet specific needs and requirements. Here, we’ll take a closer look at some of the most prevalent barcode symbologies used in scientific research, healthcare, manufacturing, and other fields.

Linear Barcodes

Linear barcodes, often known as 1D barcodes, are a common and straightforward method of encoding information that is widely used in laboratory settings. These barcodes consist of a series of vertical lines and spaces of varying widths that represent data, such as sample IDs or experiment parameters.

Code 39: An alphanumeric barcode symbology known for its versatility. It can encode letters, numbers, and a limited set of special characters. Code 39 is often used for labeling lab equipment, assets, and general inventory.

Code 128: A high-density barcode that can encode a larger set of characters. It is capable of encoding more complex data. Laboratories commonly use Code 128 for sample identification and tracking due to its capacity to encode detailed information.

2D Barcodes

2D codes, or two-dimensional barcodes, are advanced and versatile data encoding solutions. They consist of patterns of geometric shapes, like squares or dots, arranged in a grid or matrix format. 2D codes store a significant amount of data and are used for encoding complex information such as URLs, contact details, or even entire experimental protocols. Laboratories benefit from 2D codes due to their data-rich capacity and resilience in various conditions, ensuring efficient data tracking and traceability.

QR Code: 2D barcodes known for their ability to store a wide range of data, including URLs, text, and binary data. They are square in shape and include a unique positioning pattern. QR codes are used in laboratories for linking to digital records, online resources, and detailed information about samples. They are also employed in mobile applications for quick access to data.

Data Matrix: A 2D matrix barcode capable of storing a significant amount of data in a compact space. It consists of black and white squares arranged in a grid. Data Matrix is suitable for labeling small labware, vials, and containers where space is limited. It excels at encoding data like batch numbers and expiration dates.

Due to their versatility and data capacity, Data Matrix codes have become a popular choice in laboratories for tasks such as sample identification, tracking, and documentation. They are especially valuable in research, clinical, and healthcare labs where detailed information about samples and experiments is critical.

Data Matrix codes can also be standardized for global operations, as in GS1.

GS1 Barcode Symbologies:

GS1 is a global, non-profit organization that develops and maintains standards for the identification, barcoding, and sharing of data related to products, services, and locations across various industries, including retail, healthcare, and logistics.

GS1 offers a suite of barcode symbologies, including GS1-128 and GS1 Data Matrix, designed for global supply chain management and product identification. These symbologies are particularly relevant for industries where standardized product and location identification is essential, such as pharmaceuticals and healthcare.

Choosing the Right Symbology for Your Lab

Selecting the appropriate barcode symbology for your laboratory requires careful consideration of several factors:

Data Requirements: Assess the type and amount of data you need to encode. If your lab primarily deals with numeric identifiers, a simpler symbology like Code 39 may suffice. For labs with more complex data needs, consider Code 128, DataMatrix, or QR codes.

Label Size and Space: Evaluate the available space on your labware and samples. Smaller labware may require compact symbologies like DataMatrix to fit the barcode comfortably.

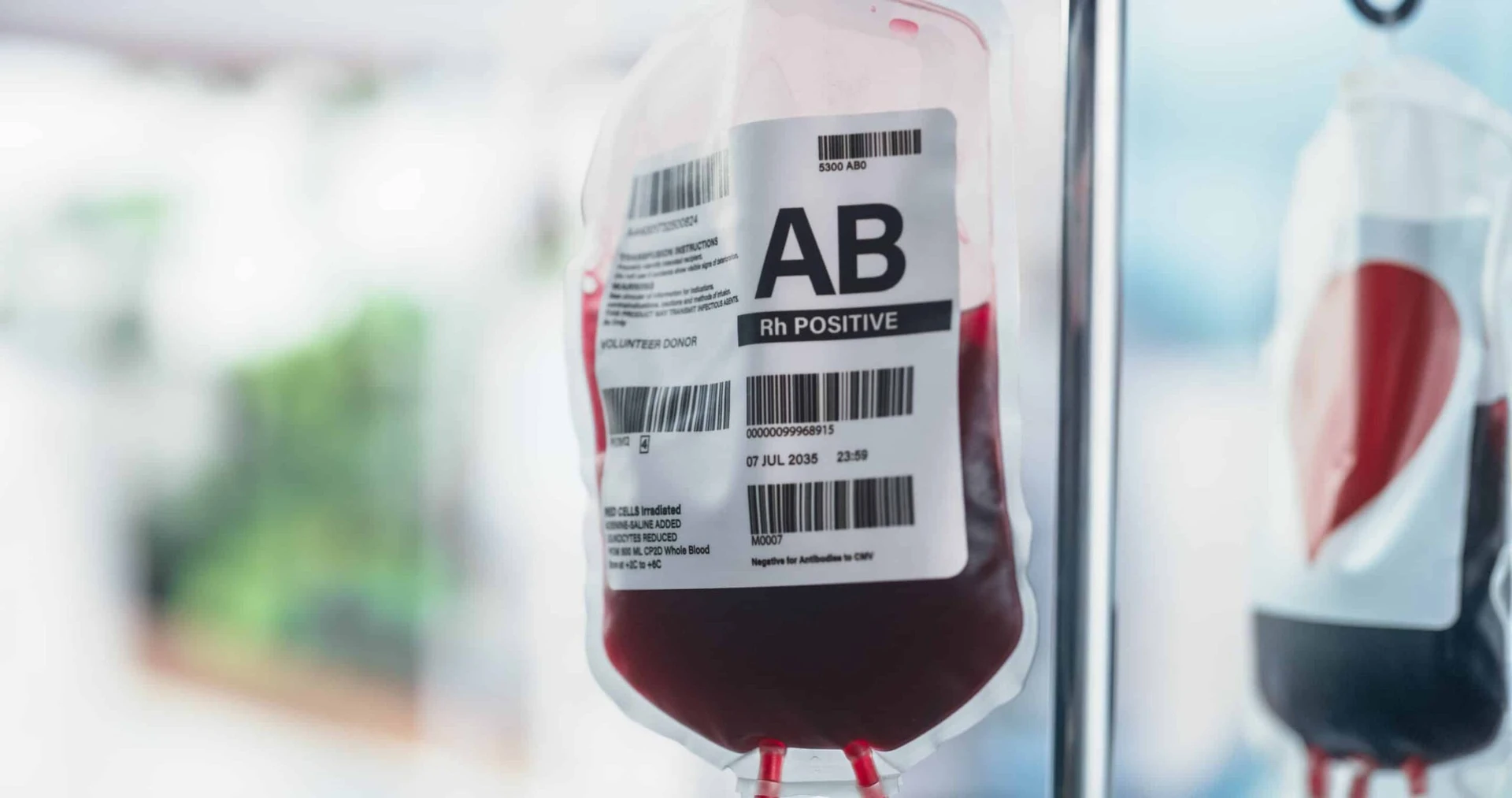

Industry Standards: Some industries, such as healthcare and supply chain management, may have specific standards and regulations that dictate the use of particular symbologies, like GS1 or ISBT 128. Compliance is crucial in these cases.

1D vs. 2D Barcodes: Decide whether 1D (linear) or 2D (matrix) barcodes are more suitable for your lab. While 1D barcodes are simpler and ideal for basic identification, 2D barcodes offer higher data capacity and are better for more complex applications.

Matching Symbologies to Lab Types and Samples

Different types of labs and samples may benefit from specific barcode symbologies:

Research Labs: Research labs dealing with a wide variety of samples and materials can benefit from the versatility of Code 128, which accommodates complex data needs.

Healthcare Labs: Clinical and diagnostic labs often require ISBT 128 for blood product labeling and GS1 DataMatrix for pharmaceuticals, ensuring compliance with healthcare standards.

Manufacturing Labs: Labs involved in manufacturing may choose GS1-128 for product labeling, allowing for seamless integration into the supply chain.

Biotechnology Labs: Laboratories working with DNA, RNA, and protein samples may prefer DataMatrix or QR codes for encoding detailed information about each sample.

Laboratory Barcode Design

Designing Effective Barcodes

Creating effective laboratory barcode designs is essential for ensuring accurate data capture, readability, and compliance with industry standards within the laboratory environment. By understanding the principles of barcode design, laboratories can optimize their workflows, reduce errors, and maintain precise data records with ease.

The art of barcode design involves not only selecting the right symbology but also considering factors such as barcode size, placement, and readability under various laboratory conditions. Each laboratory’s unique requirements may call for specialized barcoding solutions tailored to their specific needs.

Start and Stop Characters: Initiating and Ending the Barcode

Start and stop characters are essential components of a barcode. They mark the beginning and end of the encoded data, helping barcode readers recognize where to start and stop scanning. Properly placed start and stop characters are fundamental for accurate data capture.

Check Characters: Ensuring Data Integrity

Check characters, also known as checksums or error-checking characters, are added to barcodes to detect and correct errors during scanning. They enhance data integrity by verifying that the data read matches the encoded information. Including check characters is especially critical when dealing with sensitive or critical data.

Quiet Zone: Providing Space for Accuracy

The quiet zone is the clear space that surrounds the barcode. It ensures that the barcode reader can distinguish the barcode from its surroundings and read it accurately. Maintaining an adequate quiet zone is vital to prevent misreads and errors.

Density: Balancing Size and Data Capacity

The density of a barcode refers to the amount of data encoded within a given space. Balancing density is essential—too much data in a small space can make the barcode difficult to read, while too little data in a large space can be inefficient. Adjust the size and data capacity of your barcode to suit your specific needs.

High Contrast: Ensuring Readability

High contrast between the barcode and the background is vital for readability. Dark bars on a light background or vice versa are the most common and readable combinations. Ensure that your barcode labels maintain sharp contrast to prevent scanning errors.

Concatenation: Combining Multiple Data Sets

In some laboratory scenarios, it may be necessary to combine multiple data sets into a single barcode. Concatenation allows you to encode and read multiple pieces of information sequentially, streamlining processes and reducing the need for multiple scans.

For instance, in the context of ISBT 128 blood labeling, concatenated scanning ensures that related data stays together to preserve accuracy. Blood banks will scan the DIN (donation identification number) and the ABO/Rh blood group together, eliminating the risk of mismatching that information when scanned separately.

Label Material and Durability: Resisting Environmental Factors

Consider the materials used for printing barcode labels. Labels must withstand the environmental conditions in your laboratory, including exposure to chemicals, moisture, and extreme temperatures. Choose durable label materials that can maintain barcode readability over time.

Print Quality and Resolution: Achieving Precision

The quality and resolution of printed barcodes significantly impact readability. High-resolution printing and quality control processes are essential to produce clear and crisp barcodes. Regularly inspect and replace printing equipment as needed to maintain print quality.

Compliance with Standards: Meeting Regulatory Requirements

Depending on your industry and application, there may be specific standards and regulations governing barcode design. Ensure that your barcode labels comply with these standards to meet regulatory requirements and avoid compliance issues.

Testing and Verification: Ensuring Accuracy

Before widespread implementation, thoroughly test and verify your barcode labels. Use barcode verification equipment to assess readability, accuracy, and compliance with standards. Address any issues and fine-tune your label design as necessary.

Laboratory Barcode Regulations

Laboratory operations are subject to a multitude of regulations and standards that govern data accuracy, traceability, and overall compliance. In this chapter, we’ll explore the specific regulations guiding barcode usage in laboratory settings and emphasize the critical role of compliance in ensuring data integrity and traceability.

Regulatory Landscape for Laboratory Barcodes

Laboratories, particularly those involved in scientific research, healthcare, pharmaceuticals, and diagnostics, operate within a framework of regulations that require meticulous sample tracking and identification. Some of the key regulations and standards that pertain to barcode usage in laboratory settings include:

Good Laboratory Practices (GLP): GLP regulations emphasize the importance of accurate record-keeping and traceability in laboratory operations. Barcode technology helps laboratories meet GLP requirements by providing a reliable means of sample identification and tracking.

Good Manufacturing Practices (GMP): Laboratories involved in manufacturing or testing of pharmaceuticals must adhere to GMP standards, which mandate precise labeling and tracking of materials. Barcode labels ensure compliance with GMP requirements.

Clinical Laboratory Improvement Amendments (CLIA): Clinical laboratories in the United States are subject to CLIA regulations, which include provisions for tracking and identifying patient samples. Barcodes are essential for maintaining accurate patient records and ensuring sample integrity.

FDA 21 CFR Part 11: Laboratories dealing with electronic records and electronic signatures must comply with FDA 21 CFR Part 11 regulations. Barcode systems are often integrated into electronic record-keeping to meet compliance requirements.

ISO Standards: Various ISO standards, such as ISO 15189 for medical laboratories and ISO/IEC 17025 for testing and calibration laboratories, emphasize the need for accurate sample identification and traceability. Barcode usage aligns with ISO standards for quality management.

American National Standards Institute (ANSI): ANSI provides a set of widely recognized standards for assessing the quality and readability of barcodes. These ANSI barcode quality standards are essential tools in ensuring the accuracy and precision of data capture processes within laboratory environments. ANSI standards establish a grading scale, often referred to as ANSI grading, that ranges from “A” to “F,” with “A” indicating the highest level of barcode quality and “F” representing unreadable or poor-quality barcodes. These grades are determined by evaluating various factors, including symbol contrast, modulation, and the presence of defects.

Barcode Sequence Management in Laboratories

Barcode sequences are the backbone of any effective sample identification and tracking system in a laboratory. In this chapter, we will delve into what barcode sequences are, their components, the use of prefixes, custom prefixes, the importance of uniqueness, and the data capacity of barcodes in laboratory settings.

Understanding Barcode Sequences

A barcode sequence is a series of unique identifiers that are assigned to individual samples, reagents, assets, or other items in a laboratory. These identifiers are encoded into barcodes and serve as a digital fingerprint for each item. Barcode sequences play a pivotal role in ensuring the traceability and uniqueness of every entity within a lab’s workflow.

Components of a Barcode Sequence

A typical barcode sequence comprises several components:

Prefix: A prefix is a series of characters that precede the numeric or alphanumeric portion of the barcode. It can provide additional context or information about the item being identified. For example, in a clinical laboratory, a prefix might indicate the type of test or department associated with the sample.

Numeric or Alphanumeric Identifier: This is the core of the barcode sequence. It consists of a unique numeric or alphanumeric identifier that distinguishes one item from another. The length and format of this identifier can vary based on the lab’s needs and the chosen symbology.

Check Digit: A check digit is a calculated character added to the end of the barcode sequence to verify its accuracy during scanning. It helps detect errors or discrepancies in the encoded data.

Prefixes and Custom Prefixes

Prefixes are an essential part of barcode sequences, as they can provide additional information and context. Custom prefixes are user-defined and can be tailored to the specific needs of the laboratory. They allow for the categorization and organization of items based on criteria relevant to the lab’s workflow.

Should a Lab Have Custom Prefixes?

The decision to use custom prefixes depends on the complexity and diversity of items being tracked in the laboratory. Custom prefixes can be particularly beneficial in laboratories with varied sample types, departments, or projects.

Importance of Unique Sequences and Duplicate Prevention

The cardinal rule of barcode sequences in laboratories is ensuring uniqueness. Each barcode sequence should be distinct and never duplicated within the laboratory’s database. Duplicates can lead to confusion, errors, and data integrity issues. Barcode sequence management systems must be designed to guarantee the generation of unique identifiers for each item.

Data Capacity of Barcodes in Labs

The data capacity of barcodes varies depending on the symbology used. While 1D barcodes (linear barcodes) like Code 39 and Code 128 can encode a limited set of characters, 2D barcodes like DataMatrix and QR codes offer greater data capacity. The choice of symbology should align with the amount of information required for each item in the laboratory.

Ensuring Data Integrity and Efficiency

Efficient barcode sequence management is critical for maintaining data integrity and efficiency in the laboratory. It reduces the risk of errors, accelerates sample processing, and enhances traceability. With a well-designed barcode sequence management system, laboratories can confidently meet regulatory requirements and streamline their operations.

Implementing Laboratory Barcodes

Implementing barcode solutions in a laboratory involves several key steps and decisions. In this chapter, we’ll explore how laboratories can get started with barcodes, addressing aspects such as barcode generation, label design, printing methods, and the option of pre-barcoded labware. Ultimately, partnering with experts in barcode technology can greatly simplify the implementation process.

Generating Sample Barcodes

One crucial aspect of achieving this accuracy is the generation of customized barcode sequences. Laboratories need efficient methods for creating these unique identifiers, tailored to their specific data tracking needs. The process of generating barcodes is a pivotal step in streamlining workflows and enhancing the reliability of sample tracking within laboratory operations.

- Barcode Label Design Software: Laboratories can utilize specialized barcode label design software programs that allow them to create and customize barcode labels. These software tools often include features for generating unique barcode sequences and printing them directly onto labels.

- LIMS (Laboratory Information Management System): Many LIMS systems come equipped with built-in barcode generation capabilities. Laboratories can configure their LIMS to automatically generate barcode sequences based on specific data fields or sample identifiers. This streamlines the process of creating and associating barcodes with samples and experiments.

- Partners or Suppliers: Laboratories can also partner with barcode label suppliers or specialized vendors who offer custom barcode solutions. These partners can provide pre-printed barcode labels or assist in generating barcode sequences according to the laboratory’s requirements.

Designing Labels for Labware Compatibility

Labware comes in various sizes and shapes, from microcentrifuge tubes to well plates and racks, each requiring specific label dimensions and formats. Careful consideration and customization of label designs ensure that labels adhere securely, provide clear information, and fit seamlessly onto the chosen labware. Consider the following when designing label layouts:

- Label size and shape to fit the labware surface

- Positioning of the barcode within the label

- Inclusion of human-readable information for redundancy

Printing Methods: In-House vs. Pre-Printed Labels

Laboratories must decide whether to print barcode labels in-house or purchase pre-printed labels. Laboratories must weigh the advantages and considerations of each approach to select the method that aligns with their specific labeling needs and resource availability. Each method has its merits:

In-House Printing:

Advantages: Control over label production, flexibility for on-demand printing, cost savings in the long term for high-volume labs.

Considerations: Initial investment in label printing equipment and software, ongoing maintenance, and staff training.

Pre-Printed Labels:

Advantages: Quick and easy implementation, no need for in-house equipment or expertise, immediate availability.

Considerations: Limited flexibility for customization, dependence on external suppliers for label replenishment, potential cost for low-volume labs.

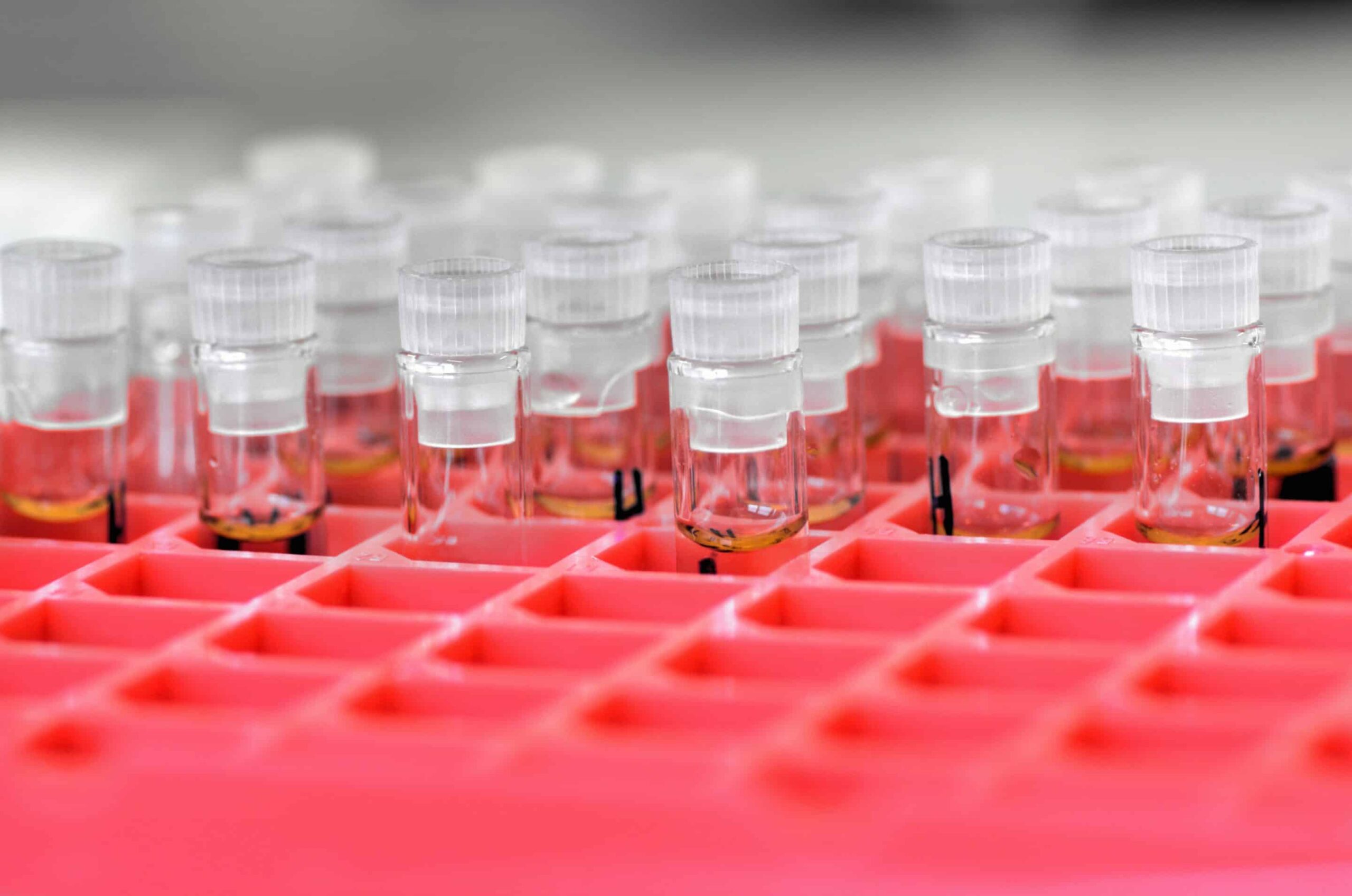

Pre-Barcoded Labware: An Alternative Solution

A relatively new alternative is to purchase pre-barcoded labware. This labware, such as tubes, microplates, or vials, comes with barcodes already applied or marked onto the labware surface by the manufacturer. This approach offers several benefits:

- Eliminates the need for in-house label printing and design.

- Ensures barcode consistency and quality.

- Streamline operations with ready to use labware.

- Reduces the risk of errors associated with label application

While laboratories have options for implementing barcode solutions independently, partnering with experts in barcode technology remains a highly recommended approach. Here’s why:

Expertise: Barcode solution providers bring expertise in barcode symbologies, label design, and data integration, ensuring a successful implementation.

Customization: Partners can tailor barcode solutions to meet the unique needs and workflows of the laboratory.

Ongoing Support: Partnerships provide access to ongoing support, updates, and maintenance, ensuring the longevity of the barcode system.

Compliance: Barcode experts can help laboratories navigate industry-specific regulations and standards to ensure compliance.

Efficiency: Partnering accelerates the implementation process, allowing laboratories to start benefiting from barcode technology sooner.

Transforming Laboratory Operations with Barcode Technology

In the world of laboratory operations, precision, accuracy, and traceability are paramount. Laboratories, whether engaged in scientific research, healthcare, pharmaceuticals, or other fields, are under constant pressure to meet regulatory standards, ensure data integrity, and enhance efficiency. Barcode technology has emerged as a game-changer, offering a path to address these challenges and usher in a new era of laboratory management.

Throughout this comprehensive guide, we have embarked on a journey to explore the vast landscape of barcode sample identification in laboratory settings. From the initial considerations of why laboratories should embrace barcode solutions to the intricate details of symbologies, design, regulatory compliance, sequence management, and implementation strategies, we have covered the essential aspects of this transformational technology.

Here are the key takeaways from our exploration:

Embrace Efficiency and Accuracy: Laboratories must recognize the value of unique sample identification through barcodes. Accuracy, efficiency, and traceability become attainable goals when laboratories fully adopt barcodes.

Choose the Right Symbology: The selection of the appropriate barcode symbology depends on the type of data, labware, and industry-specific requirements. Understanding the strengths and limitations of each symbology is crucial for optimal results.

Design with Precision: Effective barcode design encompasses factors such as start and stop characters, check digits, quiet zones, density, contrast, and label durability. Precision in design ensures successful barcode implementation.

Manage Barcode Sequences: Barcode sequences are the foundation of any barcode system. Ensuring uniqueness and preventing duplicates are paramount. Custom prefixes and well-designed management systems are essential for maintaining data integrity.

Implement with Expertise: The journey to implementing barcode solutions in laboratories is expedited and enhanced by partnering with experts in barcode technology. Partners offer expertise, customization, and ongoing support.

Barcode technology is more than just a tool; it’s a catalyst for transformation. It streamlines operations, enhances data accuracy, and empowers laboratories to meet the demands of today’s dynamic scientific landscape. Laboratories that embrace barcodes not only achieve compliance but also unlock a world of efficiency, precision, and traceability.

As laboratories continue to evolve, barcode technology stands as a reliable and innovative ally, facilitating a future where accurate sample identification and tracking are not just goals but everyday realities. The journey toward this future begins with the decision to embrace barcode solutions—a decision that promises to reshape laboratory operations for the better.

Connect with our labelling experts today

Blog article form

"*" indicates required fields