Protect and identify your samples in extreme cold with cryo labels built for -80°C freezers and liquid nitrogen storage. These durable labels are engineered to stay in place and remain scannable through every freeze, thaw, and storage cycle.

Explore cryo labeling solutions for tubes, vials, boxes, and more. Shop cryo label kits or request pre-printed options for reliable sample tracking in any cold storage workflow.

From blank labels to fully pre-marked labware, choose the approach that fits your workflow. Whether you’re printing in-house or outsourcing for convenience, there’s a cryo labeling solution that meets your needs.

Cryo labels designed for thermal transfer printing, available in a variety of sizes and formats including tube cap labels. Paired with compatible thermal transfer ribbons to print durable barcodes and data in your own lab environment.

Pre-printed cryo labels featuring barcodes, color coding, or variable data. Produced using advanced printing methods, offering enhanced durability and consistent quality without requiring in-house printing or additional equipment.

Cryo vials, tubes, or plates delivered pre-labeled or directly marked with durable identification. Ideal for saving time, maintaining consistency, and reducing handling errors during preparation and sample organization.

Solutions built for tubes, vials, and well plates where surface area is limited and print clarity is critical.

Engineered for cryo bags, straws, and curved or soft containers that require secure adhesion and shape retention.

Labels for racks, boxes, and containers—ensuring scannability and organization without disrupting frozen inventory.

A dependable choice for labeling cryovials stored in liquid nitrogen, mechanical freezers, or deep cold shipping.

Adheres securely to small plastic surfaces, with print durability that holds up to handling and thaw cycles.

Optional cap labels improve traceability and enable quick identification without removing tubes from storage racks.

Engineered for long-term cryogenic storage of tubes and vials with printed variable information.

The clear wraparound laminate shields print from solvents, friction, and handling damage during storage and retrieval.

Ensures barcodes remain scannable through freeze-thaw cycles, cleaning, and repeated physical contact.

Adheres to pre-frozen plastics without loss of tack or label integrity during cold application.

Ideal for reorganization, relabeling, or consolidation of frozen sample collections under time-sensitive conditions.

Acrylic adhesive forms an instant bond, maintaining position through freeze-thaw cycles and continued storage.

Constructed with face stocks and adhesives tested for ultra-low temperatures and chemical exposure.

Withstands immersion in liquid nitrogen and extended vapor phase storage without lifting or curling.

Ideal for plasma, cryo units, and long-term archived samples requiring verified stability and permanence.

Pre-printed cryo labels offer long-term durability and visual consistency across storage and processing workflows.

Printing methods and materials are matched to each application, supporting resistance to abrasion, solvents, and cold.

Available with color coding, pre-serialized formats, and protective finishes when added durability is required.

See which cryo label fits your workflow—request samples to test adhesion, durability, and print performance in your conditions.

Cryo labels demand precise engineering across all layers of the construction. From face stock to adhesive to image durability, every component must perform in extreme cold and withstand lab-specific handling, solvents, and storage.

Cryo label materials can be engineered to withstand contact with alcohols, DMSO, acids, and other aggressive solvents—preserving adhesion and print quality during cleaning, processing, or reagent handling.

Several cryo constructions are compatible with autoclave, gamma radiation, or ethylene oxide sterilization—protecting barcode integrity and preventing label degradation during decontamination or packaging prep.

Humidity, frost, and condensation challenge label performance at cryo temps. Specialized face stocks and adhesives maintain bond strength and prevent flagging or smudging, even in LN₂ vapor environments.

Cryogenic face stocks must maintain dimensional stability and print fidelity under extreme cold, including vapor phase and liquid nitrogen storage. We utilize engineered synthetics with low-temperature flexibility and thermal resistance to avoid delamination, cracking, or shrinkage during freeze-thaw cycling. Materials are selected for their compatibility with thermal transfer, digital, and flexographic imaging technologies, as well as for their resilience under exposure to moisture, alcohols, and handling abrasion. Thickness, finish, and surface energy are optimized to balance print quality, adhesion interface, and automatic dispensing requirements. Face stocks are validated for use on plastics, glass, and low-friction substrates commonly found in tubes, vials, straws, and cryo bags.

Cryogenic adhesives must form an aggressive bond at low application temperatures and remain intact during long-term exposure to -80°C or -196°C conditions. Our adhesive systems include cryo-tolerant acrylics formulated for secure adhesion to plastics, glass, and flexible film surfaces. Select constructions are designed to bond even at sub-zero application temperatures, enabling direct labeling of frozen containers. Performance criteria include resistance to edge lifting, migration under thaw, and chemical degradation during storage or sample processing. Testing includes adhesion strength on curved substrates, dwell-time sensitivity, and survivability through vapor-phase and immersion workflows. Adhesives comply with FDA 21 CFR 175.105 for indirect contact scenarios where required.

Topcoats and overlaminates are used to improve imaging performance, solvent resistance, and surface durability under repeated freeze-thaw exposure. Thermal transfer–optimized coatings enable high-density printing with resin ribbons, while digital imaging coatings support toner anchorage or UV-curable ink systems. Overlaminates—when used—are selected for cryogenic flexibility and clarity, providing physical protection to printed data without compromising scannability. Some constructions use integrated self-laminating features, sealing the printed image beneath a protective film layer. Coating compatibility is evaluated based on imaging method, barcode resolution, and abrasion resistance through handling and storage.

Print systems for cryogenic labels must produce high-resolution, chemically resistant images that remain legible after freezing, thawing, and physical handling. We support both thermal transfer and digital imaging technologies. For thermal transfer, resin ribbons are matched to cryogenic coatings to ensure image permanence under alcohol wipes, DMSO, and repeated contact with gloves or tweezers. For pre-printed solutions, digital and flexographic printing offer full-color, high-contrast layouts with optional protective coatings. Print durability is validated through rub testing, chemical wipe testing, and freeze-thaw cycling to ensure scannability and label integrity in high-demand environments.

Cryo labels must accommodate a wide range of labware geometries—from narrow-diameter tubes and cryovials to bags, plates, and straws. We support fully customizable die-cut formats, including wraparound designs, flag labels, cap-top indicators, and small-scale panel labels. Our constructions allow for perforations, removable segments, or multi-part label sets for use across labware and recordkeeping systems. Labels are engineered for manual or automated application, with die-cut tolerances optimized for reliable feed and alignment in high-speed dispensers or robotic handling systems. Adhesive-free zones or extended tabs can be incorporated as needed to fit specific operational workflows.

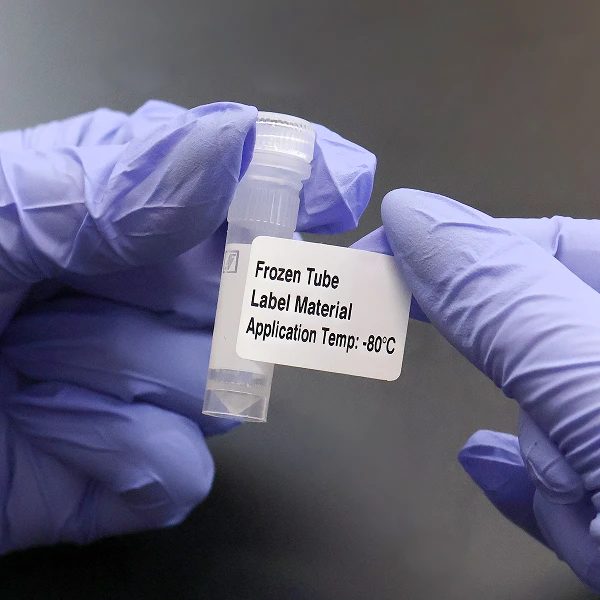

Understanding the difference between application and storage temperatures is essential when selecting cryogenic labels. A label’s ability to withstand extreme cold during storage (as low as -196°C for liquid nitrogen applications) does not imply it can be applied under those same conditions. Most cryo adhesives require a minimum application temperature — often around 0°C to 20°C — to establish an effective bond. Labels intended for use on already frozen surfaces are specially engineered with modified adhesives to enable bonding at temperatures as low as -80°C, but these are exceptions rather than the norm. Selecting the right label requires evaluating your workflow: whether labeling is done before or after freezing, how quickly samples are exposed to cryogenic conditions after labeling, and whether automation is involved. Each label construction has a specific range where optimal adhesion is achieved and retained. Proper alignment between application conditions and storage requirements is critical to avoid adhesion failure or data loss during storage and handling.

Choose from high-performance cryo label sets, each paired with a compatible ribbon. Designed for thermal transfer printing and ready to withstand even the most extreme cold storage environments.

Pre-printed cryo labels combine precise imaging with durable label materials to deliver barcodes and branding that stay legible through cryogenic storage. Using advanced print technologies we achieve fine detail, vivid color, and long-term resistance to solvents and abrasion. Each label set is engineered, serialized, and finished to meet exact specifications for laboratory use.

Pre-printed cryo labels are produced with advanced digital and flexographic imaging for exceptional sharpness and clarity. Fine detail, consistent color, and high-contrast barcodes ensure dependable scans, even on small-diameter tubes and vials stored in cryogenic conditions.

Professional printing enables a level of protection that’s difficult to achieve with in-house equipment. Each label is produced with tightly controlled ink deposition, curing, and finishing processes that maximize image permanence for long-term cryogenic storage and frequent handling.

Every cryo label set is precisely serialized and verified to maintain complete data integrity. Alphanumeric sequences, barcodes, and color-coding can be organized to match tube racks, kits, or workflows—ensuring zero duplication and effortless traceability from start to finish.

Stand-out color bands, logos or cap-markers pre-printed on cryogenic-grade labels increase visual clarity, support sample type identification, and ensure brand consistency—even after repeated freeze–thaw cycles and liquid-nitrogen storage.

Our pre-printed cryo labels can arrive with static elements (logos, color bars, part of text) ready, leaving the barcode, lot number or expiry date blank for in-lab printing—streamlining production while ensuring print quality and durability.

By pre-configuring layout, fonts, and fixed data zones, we eliminate formatting variation across batches. This ensures every label maintains consistent presentation, supports reliable scanning, and simplifies audit-ready traceability for cryogenic workflows.

From desktop printers to fully automated systems, these devices support accurate, efficient labeling across a wide range of cryogenic labware. Whether you’re printing labels in-house or integrating into a high-throughput robotic workflow, these options offer reliable performance and compatibility with a variety of tube types and sizes.

Compact desktop printers ideal for basic tube label printing with thermal transfer capabilities and flexible media handling options.

Reliable 300 dpi printing in a small footprint, commonly used in laboratories for tube, cap, and vial label production.

Durable, high-precision printers designed for continuous or die-cut tube labels, compatible with curved surfaces and tight mandrels.

Automated vertical tube labeler ideal for integration into robotic workflows. Supports filled, capped, and uncapped tube handling.

Flexible semi-automated labeler for tubes. Foot pedal or button activation simplifies print-and-apply processes in varied lab environments.

Fully automated system for labeling and racking tubes in high-throughput labs. Integrates with scanners, de-cappers, and robotic handlers.

Cryogenic labeling requires materials engineered to perform under extreme cold, moisture, and chemical exposure. These FAQs address the most common technical challenges with cryo labels, including adhesion, durability, and print performance—helping laboratories ensure clear, lasting identification for samples stored in ultra-low freezers and liquid nitrogen environments.

Cryogenic labels can withstand temperatures ranging from standard freezer conditions down to -196 °C in liquid nitrogen, depending on the construction. Many are also stable at high temperatures during thawing or sterilization. This performance depends on the interaction of adhesive chemistry and face-stock properties. Acrylic adhesives, particularly solvent-based or modified emulsion types, retain tack and elasticity even as molecular mobility slows at ultra-low temperatures. Paired with synthetic films such as polyester, polypropylene, or polyimide, they resist cracking and delamination that can occur in paper or unsupported film labels. The addition of cross-linked topcoats and laminates helps maintain print integrity during temperature swings and contact with frost, condensation, or vapor phase nitrogen. Reliable cryogenic labeling requires matching each component—adhesive, face stock, liner, and print method—to the intended storage environment and thawing process.

Application temperature defines when a cryogenic label can form a bond; storage temperature defines what the label can endure once that bond sets. Most cryogenic labels require above-freezing application, typically between +10 °C and -20 °C, so the adhesive can flow and wet the substrate. Once set, the adhesive polymerizes and maintains adhesion through long-term storage in ultra-low freezers or liquid nitrogen.

Certain constructions can be applied directly to frozen surfaces at -80 °C by using specially engineered adhesive systems. Applying any label below its rated range prevents molecular flow and reduces bond strength. Understanding both temperature ratings ensures the adhesive achieves full contact during application and remains stable across storage, thaw, and handling.

You can apply cryogenic labels to frozen tubes only if the labels are specifically designed for frozen-surface application.

Some cryo labels need at least partial thawing to achieve full adhesion, but frozen-surface constructions use modified acrylic adhesives that retain flow even at -80 °C, allowing them to grip directly onto cold, rigid surfaces. Success still depends on careful technique: any frost or surface moisture will create a barrier, so the tube must be dry before labeling. Full, even pressure across the label surface promotes molecular contact, and a short dwell period before re-immersion improves long-term bond strength. When properly applied, frozen-surface cryogenic labels remain intact through repeated liquid nitrogen immersion, thaw cycles, and handling—ideal for reorganizing or re-identifying samples already in frozen storage.

Cryogenic labels typically peel or fall off due to a temperature mismatch, surface moisture, or improper application. Adhesives formulated for room-temperature or standard freezer use become glassy and lose tack below their rated range, preventing full wet-out on the substrate. If condensation or frost is present, even a cryogenic adhesive cannot contact the surface, leading to early lift. Other common factors include insufficient dwell time before freezing, small-diameter tubes that stress the adhesive mechanically, and low surface-energy plastics such as polypropylene or polyethylene that naturally resist bonding.

Using a cryogenic-grade label, ensuring a clean and dry surface, applying with firm pressure, and allowing the adhesive to cure before freezing prevent these failures. When chosen and applied correctly, cryogenic labels maintain adhesion for years in liquid nitrogen and ultra-low storage.

Thermal transfer printers using resin ribbons deliver the most dependable and widely used results for printing cryogenic labels in-house. Resin ribbons form a heat-fused image that bonds directly to the label’s topcoat, producing a dense, abrasion- and solvent-resistant print that can withstand liquid nitrogen, dry ice, and repeated freeze–thaw cycles. They also resist alcohols, DMSO, and other common lab solvents that quickly degrade wax or wax/resin ribbons. Optimal performance depends on selecting a matched system—the printer model, ribbon formulation, and cryogenic label material must be engineered to work together. This ensures the correct heat, dwell time, and pressure for complete ribbon transfer and crisp, durable imaging.

While thermal transfer printing offers excellent durability and is the standard for on-demand cryogenic labeling, it represents one level of a broader durability spectrum. Pre-printed cryogenic labels, produced using advanced converting processes, can offer even greater longevity through specialized coatings, UV-cured inks, and protective laminates. The highest durability comes from permanent pre-marked labeling methods, where the identification is fused or etched directly into the substrate. Each method offers trade-offs between flexibility, permanence, and throughput—but for most laboratories, properly printed thermal transfer labels with high-quality resin ribbons provide a proven, high-performance solution.

Many cryogenic labels are engineered to withstand solvents and disinfectants common in laboratory environments. Resistance depends on the entire label construction: the face stock, topcoat or laminate, adhesive, and print method. Polypropylene and polyester films provide superior chemical and moisture resistance, while protective laminates or self-laminating sections shield the printed information from degradation. When paired with resin ribbon printing, these constructions can endure frequent exposure to alcohols, DMSO, xylene, and acetone without smudging or loss of adhesion.

Among print-on-demand options, wrap-around cryogenic labels deliver the strongest combination of cryo survival and chemical resistance. Their built-in laminate seals the printed area completely, protecting both the image and the adhesive from harsh solvents and repeated handling. For applications involving prolonged chemical exposure or sterilization, select cryogenic labels rated as chemical-resistant or solvent-proof to maintain long-term readability and reliable adhesion under extreme laboratory conditions.

Wrap-around cryogenic labels are self-laminating constructions that wrap 360° around a tube or vial and adhere to themselves for added durability. The overlapping laminate section forms a built-in protective layer that seals in the printed information, protecting it from solvents, frost, and mechanical abrasion. This configuration also distributes stress evenly along the tube’s curvature, making it especially effective on small-diameter tubes, cryo vials, and microcentrifuge samples. By adhering to both the tube surface and themselves, wrap-around cryogenic labels provide exceptional bond strength even in liquid nitrogen or vapor-phase environments. The transparent overwrap keeps barcodes scannable while preventing fading, peeling, or solvent penetration. They are ideal for demanding workflows involving frequent handling, washing, chemical exposure, or freeze–thaw cycling.

Well-constructed cryogenic labels remain adhered and legible through multiple freeze–thaw cycles when applied correctly. Cryogenic adhesives use flexible polymer systems that expand and contract with the substrate as it moves between ambient and ultra-low temperatures, maintaining a continuous bond. The face materials— typically polyester or polypropylene—resist brittleness and cracking, while coatings or laminates protect printed information from condensation or ice formation.

However, consistent performance depends on application quality and adhesive cure. Applying the label above its minimum rated temperature, ensuring the surface is dry, and allowing sufficient dwell time before freezing enable full adhesive anchoring. Cryo labels rated for repeated freeze–thaw performance preserve barcode integrity and sample traceability throughout long-term storage and repeated handling.

Many cryogenic labels are compatible with automated applicators, but not all constructions are suited for automation. Automation-ready cryogenic labels feature precise die-cuts, consistent release liners, and adhesives designed for smooth mechanical application. Proper liner release tension ensures reliable feeding through tube or plate labelers, preventing skewing or edge lift. The adhesive must also have the right balance of tack and flow—aggressive enough for immediate bonding, but controlled to avoid premature adhesion during placement. Equipment compatibility depends on label size, spacing, core diameter, and unwind direction. Selecting cryogenic labels tested for automated systems ensures consistent placement accuracy and dependable adhesion through subsequent freezing and thawing. For high-throughput labs and biobanks, automation-ready cryogenic labels improve precision, throughput, and repeatability while maintaining long-term durability under cryogenic storage conditions.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields