Barcode labels are essential for identifying, tracking, and managing assets in the most demanding environments. From cryogenic vials to vulcanized rubber, our barcode labels are engineered for performance where others fail. With decades of experience in symbology, materials, and scanning systems, we build barcode solutions that deliver reliable results every time.

Barcode-enabled tracking is essential in high-stakes environments, where accuracy and durability can’t be compromised. We engineer barcode labels to integrate seamlessly into your asset, inventory, or sample tracking systems—no matter the industry. With expertise across materials, symbologies, and application environments, we make sure your barcodes perform exactly as they should.

Barcode labels simplify data capture and improve accuracy across industries, from lab tracking to warehouse logistics. They enable fast scanning, reduce manual entry errors, and support efficient inventory and asset management. With the right design and materials, they perform reliably in even the toughest conditions.

Fast, accurate data collection

Compatible with many symbologies

Scannable in harsh environments

Customizable for any application

From Code 128 to Data Matrix, each symbology has strengths based on the data type, size constraints, and scanning equipment. Layout decisions—like quiet zone spacing, contrast, and orientation—can make or break scan reliability. A strong design ensures your barcodes perform consistently across systems and workflows.

Effective barcode design ensures reliable scanning by following technical standards for each symbology. This includes proper quiet zones, sufficient contrast, etc. A well-designed barcode label balances functional layout with data integrity, supporting consistent performance from printing to point-of-use.

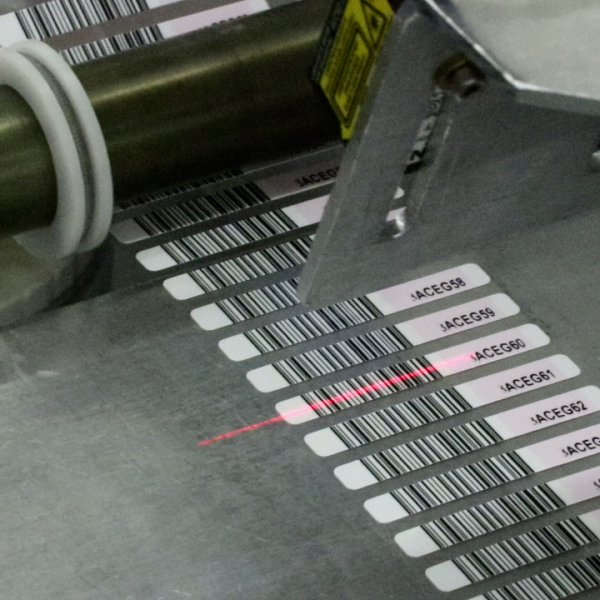

Print technology affects both the look and longevity of your barcode. Thermal transfer is popular for its durability, while digital and flexographic printing support higher volumes and color options. Whichever you choose, sharp edges and high contrast are key to fast, accurate scans.

Not all labels are built the same. Share a few details about your product or environment, and we’ll recommend a label designed to stick, stay readable, and hold up under pressure.

Barcode success depends on more than just material durability—it’s also about how the barcode is designed, formatted, and encoded. We consider how it will be scanned, what systems it connects to, and how much information it needs to carry. From clean contrast to complex data encoding, we design barcodes to work exactly as your process demands.

Barcodes come in many formats, each designed to suit specific data types, sizes, and scanning environments. The right symbology depends on what’s being tracked, how it’s scanned, and how much information needs to be encoded. We’re deeply familiar with both 1D and 2D formats, from compact Data Matrix codes on small curved surfaces to Interleaved 2 of 5 barcodes used in large-scale logistics.

Our team is experienced in matching the right barcode format to the product, the system, and the real-world use case. This ensures every label we deliver is not just scannable—but optimized for how it’s actually used.

Barcode symbologies define the rules for encoding data into scannable patterns of bars and spaces. Understanding these symbologies helps ensure compatibility with scanners, data systems, and regulatory standards. Each symbology has specific rules for encoding, sizing, and error handling, making the right choice critical for performance and compliance.

Different symbologies exist to meet the unique requirements of industries and applications, such as tracking, labeling, or product identification. Some symbologies prioritize simplicity and universal compatibility, while others focus on data density or security.

Each symbology encodes data using unique character sets

Some support variable length; others require fixed formats

Linear barcodes like Code 39, Interleaved 2 of 5, and GS1-128 are commonly used in logistics, healthcare, and manufacturing for tracking and regulatory compliance. 2D barcodes, such as QR Codes and Data Matrix, are ideal for storing more complex or larger amounts of data in smaller spaces. Industry standards—like those from GS1—often dictate which symbology to use, ensuring compatibility with scanners and software across global supply chains.

Code 128 is a high-density linear barcode symbology capable of encoding alphanumeric characters and special symbols. It is widely used in logistics, healthcare, and retail for applications requiring detailed tracking, such as shipping labels and medical products. Its flexibility and compatibility with global standards make it a reliable choice.

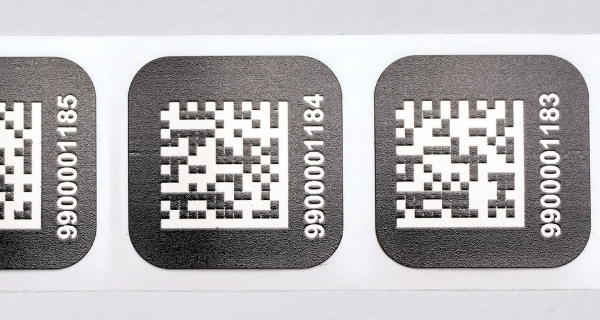

Data Matrix is a compact 2D barcode symbology that stores large amounts of data in a small space. Its built-in error correction ensures readability even if the code is partially damaged. Frequently used in laboratories, biobanks, and electronics, it is ideal for labeling small items and precise tracking. Its efficiency in compact spaces makes it indispensable.

QR Codes are versatile 2D barcodes that can store a wide range of data, including URLs, text, and serialized information. Known for their high scanning speed and resilience to damage, they are used in logistics, marketing, and healthcare. QR Codes excel in applications requiring quick access to datasets, combining reliability with convenience.

Interleaved 2 of 5 is a numeric-only linear barcode symbology designed for compact, high-density encoding. Its durable design makes it ideal for industrial applications like tire manufacturing and warehousing. ITF is commonly used on corrugated packaging, where readability is critical even on rough, challenging surfaces.

PDF417 is a stacked linear barcode symbology that combines high data capacity with compact design. It is often used in logistics, shipping, and transportation for encoding detailed information like manifests or licenses. PDF417’s robust design ensures reliability and efficiency in high-volume workflows, making it indispensable for data-intensive operations.

EAN-13 is a linear barcode symbology used primarily in retail and libraries for product identification. It encodes 13 numeric digits, including country codes, manufacturer identifiers, and product numbers. EAN-13 ensures global compatibility and efficient cataloging for inventory systems. Its simplicity and reliability make it integral for archives.

Barcode design is a balance of precision and pragmatism. Quiet zones, contrast ratios, and X-dimensions all affect scannability — especially when space is tight or the label will face wear, frost, or chemical exposure.

A barcode’s ability to scan reliably depends on more than just the data it carries—it depends on how it’s designed. We account for sizing, contrast, quiet zones, orientation, and layout to ensure the barcode works in your actual environment, not just in theory. Every design decision is made to support high scan accuracy, even in tight spaces, curved surfaces, or regulated formats.

Effective barcode design balances readability, durability, and compatibility with scanning systems. Choosing the right size, contrast, and symbology ensures consistent performance in any environment. Attention to placement and environmental conditions further enhances reliability and accuracy.

Select symbology based on data length and density

Set bar and space widths to match scanner resolution

Encode variable data with proper character formatting

Maintain minimum X-dimension for intended print method

Contrast between barcode elements and background is essential for accurate scanning. We select face stocks, inks, and ribbon combinations that create high optical contrast, even in harsh environments or when the label is exposed to chemicals or UV. For reflective or colored surfaces, we incorporate underlayers or special coatings to maintain scan reliability across devices.

The quiet zone is the margin around a barcode that signals the scanner where the code begins and ends. We ensure this space is preserved during printing, cutting, and application, even on small-format labels. In workflows with tight tolerances or automated inspection systems, we validate quiet zone integrity as part of our quality process.

Check digits are additional numbers included in barcodes to verify the accuracy of scanned data. They are calculated using a mathematical formula based on the other digits in the barcode. Commonly used in symbologies like EAN-13 and Code 128, check digits help detect errors during scanning.

Modern barcodes are equipped with features that extend their usability and reliability. Many barcode symbologies support advanced features that improve accuracy, add flexibility, and reduce scanning errors. Concatenation allows multiple data fields to be combined into a single scan, streamlining workflows and minimizing confusion.

Other enhancements, like prefixes, suffixes, and structured data formatting, support more complex scanning environments. These features are especially useful when labels are exposed to wear, chemicals, or scanning inconsistencies.

Concatenation links multiple data fields together in one scan

Error correction recovers information from damaged labels

Encryption protects sensitive or regulated information

Anti-counterfeit features verify label authenticity

These features are especially useful in regulated industries, high-throughput environments, and systems requiring precise traceability. When used correctly, they reduce the risk of misreads, eliminate manual data entry, and simplify scanning across multiple formats. Some features are built into the barcode itself, while others are configured in your printer, scanner, or software. Understanding what’s possible helps you build a barcode strategy that’s efficient, resilient, and ready to scale.

Error correction allows 2D barcodes like Data Matrix and QR Codes to remain readable even when partially damaged, obscured, or curved. We tune error correction levels based on your label’s expected wear—from cryo-frosted tubes to scuffed medical trays to industrial components. This ensures scan reliability under real-world conditions where damage, distortion, or imperfect placement might otherwise result in data loss.

Whether you’re tracking assets, samples, or components, serialization forms the backbone of traceability. We support structured and sequential serialization systems with database integration and real-time generation at the point of print. For complex workflows, we ensure serialization aligns with your system rules and label layout. This prevents duplication, enables reconciliation, and keeps your operation audit-ready.

Some barcodes carry sensitive or proprietary data that must be protected against unauthorized access, duplication, or tampering. We support encrypted barcodes, digitally signed data, and other security measures—including microtext and anti-copy design elements—to ensure authenticity and prevent counterfeiting. These features are especially valuable in pharmaceutical, aerospace, and high-value manufacturing environments.

Barcodes aren’t just printed—they’re structured, encoded, and formatted to match your system. We help you generate barcodes, design the full label, and choose the right materials and print method based on your workflow. Whether you’re printing in-house or need pre-printed solutions, we make sure the barcodes work the way they’re supposed to.

There’s no one-size-fits-all approach to barcoding. The best method depends on your industry, how often your data changes, and whether you need the barcodes embedded in a process or applied later. Generating barcodes in-house gives you full control over data and timing but requires the right software, printer, and training.

Sourcing barcodes from a supplier simplifies the process and ensures consistency, especially if you don’t have the infrastructure in place. Direct part marking is ideal when the barcode needs to be permanently tied to the item from the start. You’ll also need to consider print quality, environmental durability, and data accuracy. Each option has trade-offs between flexibility, cost, and operational complexity.

Design and generate your own barcodes using professional software like BarTender or NiceLabel. These platforms support a wide range of symbologies and let you control data formatting, layout, and print settings. Ideal for facilities that need flexibility, variable data, or integration with databases and existing systems.

Outsource your barcodes to reduce complexity and ensure consistent, high-quality results. We specialize in designing and printing barcodes that scan reliably, even in demanding environments. Pre-printed solutions are perfect when your data is stable and accuracy is critical.

For lab environments, we offer labware with barcodes permanently applied using ceramic marking, cured inks, or laser etching. These methods create durable, scannable identification that withstands harsh conditions and repeated handling. Pre-barcoded labware simplifies workflows and supports long-term traceability.

If you’re printing barcode labels in-house, we’ll help you set up a reliable, efficient system with the right tools and materials. We support industry-leading software like BarTender and NiceLabel to help you generate barcodes, structure your data, and design complete labels. With the right combination of media, printers, and software, your barcodes will scan cleanly and perform in any environment.

BarTender and NiceLabel setup and integration

Label kits optimized for your use case

Printer and ribbon recommendations based on workflow

Support for GS1, UDI, and lab-specific barcode formats

Compact systems for lower-volume use in labs, clinics, or smaller production lines. Compatible with thermal ribbons and various label sizes for daily print needs.

Built for high-volume environments and larger label formats. Offer fast print speeds, robust construction, and compatibility with durable ribbons and synthetic materials.

Integrate real-time thermal transfer printing with automated applicators. Designed for high-speed workflows, these systems reduce manual handling and improve label placement accuracy.

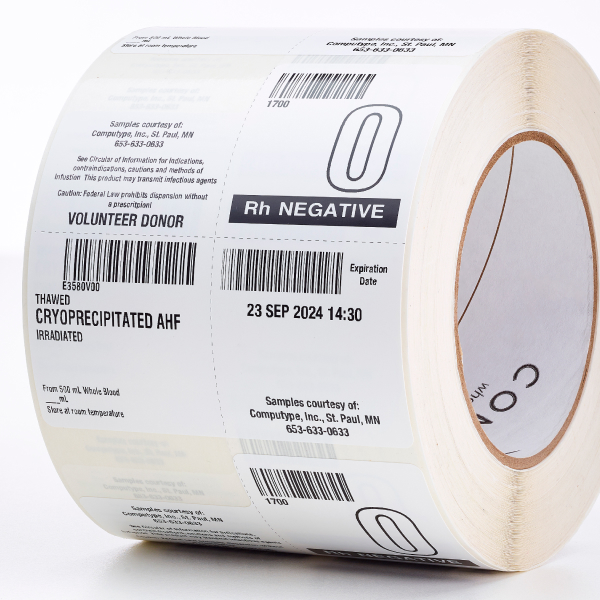

For customers who prefer not to print in-house, we offer fully pre-printed barcode labels that are ready to apply. Every label is verified during production for scan quality, formatting, and data accuracy. We can deliver serialized sets, matched kits, or custom layouts—whatever your system requires.

Sequential or variable data encoding

Multiple barcodes or segments per set

Matched human-readable and barcode content

Graded and tested to ISO 15415/15416 standards

Flexographic printing employs flexible relief plates to transfer ink onto various substrates, making it ideal for high-speed, large-volume barcode label production. This method offers excellent print quality on both porous and non-porous materials, accommodating multiple colors through its multi-station presses. Once set up, it becomes highly cost-effective for long runs with static or serialized barcode content.

Digital printing includes both inkjet and digital offset technologies, offering excellent flexibility for barcode printing with variable data. Inkjet systems spray ink directly onto the label surface, making them ideal for short runs and real-time serialization, while digital offset uses an imaging plate to deliver higher resolution and tighter control over fine lines and contrast. Both methods produce high-quality, scannable barcodes.

Thermal transfer printing uses heat to transfer ink from a ribbon onto the label material, producing durable, high-definition barcodes. This method supports a wide range of substrates, including paper and synthetic materials, and is renowned for its resistance to fading and smudging. Thermal transfer is particularly suited for applications requiring long-lasting labels, such as asset tagging and inventory management.

When barcodes fail to scan, the consequences ripple through entire systems—especially in regulated or high-volume environments. That’s why we don’t just print barcodes, we measure, verify, and validate them to ensure they perform exactly as needed. Our quality assurance process goes beyond appearance to ensure every code meets the highest standards for grading, scan success, and compliance.

Grading evaluates barcodes by assigning a quality score that predicts how well they will scan across devices and environments. This process measures factors such as contrast, edge sharpness, and quiet zones. Barcodes are graded on a scale, typically from A to F, based on their adherence to standards like ISO/IEC.

Higher grades indicate better performance and reliability, while lower grades signal the need for adjustments in printing or design. Grading is especially important in industries like logistics, where barcodes must remain scannable through multiple handling stages. It also supports compliance in regulated industries by ensuring labels meet strict standards. Regular grading helps businesses identify and resolve issues before barcodes are deployed.

Barcode quality control measures ensure barcodes are reliable and easy to scan. Verification, validation, and grading are used to evaluate barcode performance and compliance with standards. These measures identify potential issues like low contrast or poor alignment before barcodes are deployed. Quality control is essential to prevent scanning errors and ensure compatibility. Regular checks during production help catch inconsistencies early and reduce costly rework. By maintaining barcode quality, businesses can improve efficiency and meet industry requirements.

Verification evaluates a barcode’s physical characteristics to ensure it meets readability standards, checking factors like contrast, quiet zones, and alignment against ISO/IEC or industry-specific guidelines. It also confirms that the barcode is printed with sufficient quality for consistent scanning.

Validation confirms that a barcode encodes the correct data and functions as intended within a system, testing barcodes in real scenarios to ensure they meet operational or regulatory requirements. It helps identify formatting errors or data structure issues that might not be visible during design or printing.

When we deliver pre-printed barcode labels, every code is tested for quality, readability, and consistency. We follow global grading standards and real-world validation methods to ensure the labels will scan reliably in your environment. From small lab vials to warehouse cartons, we apply the same rigorous process.

Verified to ISO 15415/15416 grading standards

Scanned during production to detect flaws early

Checked for correct data encoding and structure

Automatically voided and reprinted if errors are found

Barcodes are used across nearly every industry, but the demands placed on them vary widely depending on the product, environment, and regulatory landscape. We design barcode labels that meet the specific needs of each application—from tight label spaces in the lab to rugged handling in warehouses. Whatever you’re tracking, we help ensure every scan is successful and every label holds up.

We work with customers in regulated, high-performance, and asset-heavy industries where barcode labels are critical for identification and tracking. Each industry has unique constraints—whether that’s space, durability, compliance, or scanner compatibility—and we build labels to match. Our solutions are engineered to perform across every environment.

Laboratories and biobanks

Pharmaceutical and medical device manufacturing

Warehousing and industrial logistics

Barcodes in blood banking must meet ISBT 128 standards for encoding donor ID, product type, and expiration data. We produce multi-label sets with scannable segments, durable adhesives, and layouts that support bedside and lab automation. Every label is tested for scan accuracy, compliance, and clean readability under refrigeration and handling.

Under FDA UDI requirements, barcodes must encode standardized identifiers like GTIN, lot, and expiration in a readable and scannable format. We design and print labels using GS1 and HIBCC-compliant symbologies, verified to meet grading requirements. Our labels are optimized for scannability across curved surfaces, tight spaces, and sterile packaging.

Library barcodes follow strict formatting rules, often using Codabar, EAN-13, or ISBN to support cataloging, circulation, and digital archiving. We provide durable, scannable labels that last through decades of shelving, handling, and scanning across systems. Labels are designed for integration with library management software and long-term collection integrity.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields