Warehouse environments demand durable labeling solutions. These solutions are designed for consistency, durability, and seamless workflow integration.

Each construction is selected to match storage conditions, application surfaces, and barcode scanning requirements across warehouse operations.

Warehouses rely on consistent, accurate labeling across containers, storage locations, and outbound units. From fixed racking to returnable totes, each application requires a label construction matched to its handling, surface, and environment.

Static locations demand labels that remain readable through dust, impacts, and airflow over time.

High scan rates increase wear, especially on exposed rack beams and upright supports.

Durable synthetics and strong adhesives help preserve location integrity across warehouse zones.

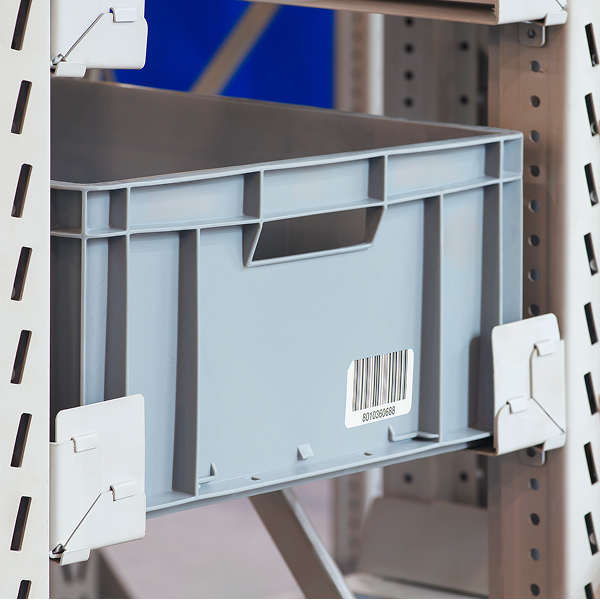

Reusable containers face abrasion, detergent exposure, and constant movement between touchpoints.

Label failure disrupts tracking and slows inventory reconciliation or return processing.

Chemical-resistant materials and proven adhesives ensure accurate ID from dispatch to return.

Pallets pass through high-touch zones where friction, dust, and stacking can degrade label readability.

If scannability drops, the entire inventory flow gets delayed or misrouted.

Strong face stocks, barcode clarity, and removable options support accurate unit-level control.

Injection-molded crates and totes often require permanent tracking that resists wash and abrasion.

In-mold labeling bonds directly to the part, eliminating adhesive failures or post-mold steps.

Ideal for closed-loop logistics where tracking durability matters more than label removability.

Inventory labeling tracks goods, not just locations—especially during repack, rework, or long-term hold.

Labels must stay readable across storage conditions, product surfaces, and time in inventory.

Variable data, barcode formats, and material flexibility enable accurate item-level visibility.

Request a sample to see how each warehouse label type performs across your storage surfaces, container materials, and workflows.

Warehouse labels must perform in challenging conditions—abrasion, temperature changes, and industrial cleaning are all part of the daily cycle. Whether applied in-house or received pre-printed, these labels are constructed for long-term performance and integration with warehouse systems, printing hardware, and container materials.

Blank label kits pair with thermal transfer printers and include compatible ribbons for optimal image durability. Resin ribbons combined with rugged face stocks like polyester or polypropylene resist abrasion, moisture, and cold.

Pre-printed labels allow for full customization and enhanced performance. UV-cured inks, precoats, and aggressive laminates offer superior durability. Barcode sequencing is verified to prevent duplicates across pallets, totes, or rack IDs.

In-mold labels are embedded during plastic molding to create a scannable, permanent identifier. Common on reusable totes, they eliminate adhesive failure and stay readable through handling, stacking, and industrial cleaning.

Engineered for high scan accuracy with clean die cuts, durable facestocks, and crisp thermal transfer imaging—essential for serialized inventory and tote-level tracking.

Constructed with FDA- and FSMA-aligned materials that resist chemicals, moisture, and abrasion—maintaining legibility and adhesion through sanitation and food-safe workflows.

Designed for operational flexibility with removable or cover-up constructions that enable tote rotation, reassignment, and relabeling—without damaging container surfaces.

Stacking, scraping, sliding, and sorting all introduce friction. These labels are engineered with rugged face stocks, scratch-resistant coatings, and high-durability ribbons that maintain barcode clarity through frequent handling.

Reusable containers undergo industrial wash cycles and exposure to caustic detergents and disinfectants. Labels maintain adhesion and print stability through repeated cleaning, ensuring traceability survives harsh sanitation protocols.

Labels face thermal extremes during refrigerated storage, outdoor loading, and long-haul transport. Materials and adhesives are selected to remain flexible, bonded, and legible—even in freezing temperatures or fluctuating climate zones.

The face stock is the printable layer of the label and must be chosen based on both durability needs and container material. In warehouse settings, polypropylene and polyester face stocks are most common. Polypropylene is flexible, cost-effective, and holds up well under abrasion, moisture, and cold storage. Polyester offers higher durability, especially in environments involving stacking, friction, or exposure to cleaning agents. For short-term or movable labels, coated paper face stocks are sometimes used, especially in print-on-demand systems. These are ideal for pallet staging or temporary bin assignments but are not recommended for reusable containers. The face stock also plays a major role in barcode clarity—higher-resolution films are often used to ensure scannability even after weeks or months in rotation. Matching the face stock to the container, ribbon, and print method ensures the full construction performs as needed across the label’s lifecycle.

Adhesive performance can make or break a warehouse labeling strategy, especially when labels must endure cold, cleaning, and constant handling. For reusable transport packaging, permanent acrylic adhesives are most commonly used. These adhesives are engineered to bond to low surface energy plastics like polypropylene, commonly found in bins, crates, and totes. They resist edge lift, hold strong through wash cycles, and remain stable in both hot and cold environments. For highly textured or curved surfaces, we offer high-tack adhesives that provide extra hold without compromising barcode visibility. All adhesive formulations are carefully tested against friction, plastic compatibility, and environmental exposure to ensure a reliable bond. For short-term applications or locations that require labeling flexibility, removable adhesives are also available, though permanent options are far more common in warehouse operations. Selecting the right adhesive ensures the label won’t shift, peel, or fail during scanning, cleaning, or stacking.

Topcoats and laminates serve as protective barriers that keep barcodes and text readable over time, even in high-contact or chemically aggressive environments. A topcoat is a thin layer applied to the face stock to help thermal transfer ribbons bond better and resist abrasion or chemical degradation. This is especially important for print-on-demand systems where in-house ribbon performance varies. Laminates are thicker clear films applied over the label after printing, often during the finishing process for pre-printed labels. These laminates provide long-term protection against scuffing, solvents, and wash cycles. One common construction includes a polypropylene laminate over a printed polyester face stock—ideal for tote labeling in reusable logistics. Whether you’re protecting a label on a returnable bin or preventing pallet labels from smearing during handling, protective layers are often the key to extended scan life and label legibility in warehouse environments.

Image durability depends not just on the face stock, but also on the printing system used. For print-on-demand labeling, thermal transfer ribbons—especially resin and wax/resin blends—are critical. Resin ribbons offer the highest durability, bonding tightly to coated synthetics like polyester or polypropylene to resist smudging, abrasion, and chemical attack. They’re the standard for labels applied to reusable containers or exposed to industrial cleaning. Wax/resin ribbons offer a balance of durability and economy for more moderate environments. For pre-printed labels, we use UV-cured inks and custom print processes to maximize resistance to solvents, abrasion, and environmental exposure. These inks bond deeply into the face stock and can be paired with laminates or varnishes for additional protection. All ribbon and ink systems are carefully matched to label materials and end-use conditions, ensuring consistent readability even after repeated scans, stacking, and washing.

All of our blank warehouse labels are designed for thermal transfer printing and are compatible with common industrial printer models from brands like Zebra, TSC, CAB, and more. Each label kit includes a matching thermal transfer ribbon, ensuring print performance without the guesswork. Labels can be printed in-house as needed using standard software and printing equipment, whether applied manually or through semi-automated print-and-apply systems. For customers with existing hardware, we can adjust core sizes, roll diameters, or unwind directions to fit seamlessly into your workflow. For automation-focused environments, labels are built to dispense cleanly without jamming or misalignment. Whether you’re labeling totes during order fulfillment or bins during intake, our labels are engineered to match print hardware and application needs across the warehouse.

Label design plays a crucial role in workflow efficiency, scan accuracy, and visual clarity. For print-on-demand environments, we support label software such as Loftware and BarTender, which allow users to design and manage variable data, barcodes, and layouts in-house. These tools integrate with warehouse management systems to ensure alignment with bin locations, order tracking, or pallet staging. For pre-printed labels, we offer full-service design support, including custom layouts, branded color schemes, human-readable elements, and directional indicators. Color-coded designs can support picking and packing processes, while serialized barcodes ensure every tote, pallet, or location has a unique identifier. We also offer sequencing and duplication safeguards, ensuring traceability throughout the supply chain. Whether printing labels on demand or requesting professionally printed batches, thoughtful design ensures fast recognition and scanning reliability.

Choosing the right printer ensures reliable barcode production, scan accuracy, and smooth throughput. These models are well-suited for printing warehouse labels across racks, totes, pallets, and more.

Compact desktop models ideal for lower-volume warehouse tasks like staging or bin labeling. Supports thermal transfer with matched ribbons.

Reliable desktop printers for mid-range labeling needs. Strong compatibility with ribbons and label kits used in bin and tote labeling.

User-friendly tabletop printer with robust industrial-grade performance. Designed for high-resolution thermal transfer printing of durable synthetic labels.

Durable industrial printers built for high-volume workflows. Handles large label rolls and delivers fast, consistent printing across long shifts.

Two-color thermal transfer printer ideal for labeling that requires hazard symbols, color-coding, or dual-color formats in warehouse workflows.

High-performance printer series made for automation. Easily integrates with label applicators or workflows needing consistent print quality.

Have questions? We’re here to help.

Contact us to connect with a specialist who understands your industry and can provide the right solutions for your business. Let’s start a conversation.

Take advantage of our volume discounts for bulk orders. Reach out to us for a personalized quote tailored to your needs.

"*" indicates required fields