As laboratories adapt to the demands of modern research and industry standards, the spotlight on integration becomes increasingly intense. Imagine a web of interconnected processes, where every component plays a crucial role, and the key to success lies in their seamless collaboration.

Integration, a term frequently discussed but sometimes elusive in its practicality, takes center stage in this exploration. Far beyond a technical checkbox, integration serves as the linchpin of a well-functioning laboratory system. It’s the thread that weaves together the intricate tapestry of processes, from barcodes and scanning to labels and data integration.

The goal is to create a unified and efficient workflow, where data and samples can flow seamlessly between various components of the laboratory system. This integration is essential for optimizing efficiency, reducing errors, and improving overall productivity in a laboratory setting.

We can identify three primary areas of integration:

- Instrument and hardware integration, which focuses mainly on connecting and coordinating various components such as analytical instruments, robotic systems, sensors, etc.

- Data integration, which focuses on the varied programs and data sources within a lab, including unique sample IDs, Laboratory Information Management Systems (LIMS), Electronic Lab Notebooks (ELN), data analysis tools, and instrument control software.

- Workflow Integration, which focuses on the many meticulous steps and tasks happening in a laboratory workflow, minimizing manual intervention and reducing the risk of errors.

Ensuring compatibility and cohesion between these three categories is the primary objective of integration. Although this can seem daunting with so many variables, the complexities that arise are often a result of improper planning, or a failure to build a data-driven foundation. Overcoming these complexities requires a collaborative effort between laboratory staff, IT professionals, and solution providers. Successful integration not only streamlines laboratory processes but also enhances the overall efficiency and reliability of scientific workflows. It’s an ongoing process that evolves with the technological landscape and the specific needs of the laboratory.

Integration Building Blocks

As we embark on the journey of streamlining laboratory processes through integration, it’s essential to understand the bedrock principles that form the backbone of a seamlessly orchestrated system. In this section, we delve into the fundamental building blocks of lab automation integration. These foundational elements serve as the architectural pillars, ensuring the reliability, efficiency, and precision of automated workflows.

Barcode Labels

In the intricate world of lab automation, the ability to swiftly and accurately identify, track, and manage a multitude of samples, equipment, and data stands as the linchpin for operational success. At the forefront of this efficiency revolution lies our first essential building block: barcodes.

Barcodes are more than mere strips of lines; they are the standardized language that empowers automated systems to navigate and optimize processes that were once labor-intensive and error-prone. Think of them as the digital bridge that seamlessly connects physical entities with their corresponding data in the digital domain.

From the meticulous tracking of samples to the precision of inventory management, barcodes play a pivotal role in transforming manual, time-consuming tasks into streamlined, error-resistant operations. In the grand narrative of lab integration, barcodes emerge as the unsung heroes, quietly revolutionizing the landscape and setting the stage for a more efficient and interconnected laboratory ecosystem.

At its core, the primary function of barcodes in the laboratory landscape is to provide a unique identifier for each individual sample. This distinctive code acts as a digital fingerprint, ensuring that every sample is not just a part of the collective whole but a singular entity recognized and tracked with unparalleled precision.

Beyond their role as unique identifiers, barcodes serve as catalysts for a spectrum of streamlined operations within lab automation. From enabling dynamic routing to facilitating real-time data entry and seamless sample tracking, the impact of barcodes extends far beyond mere identification.

Yet, the effectiveness of a barcode goes beyond its mere presence. The symbology chosen, the sequence encoded, the design intricacies, and the image contrast—all these factors contribute to the success of a barcode in the laboratory setting. It’s not just about having a barcode; it’s about having the right barcode. Let’s unravel the nuances of symbology, sequence, design, and contrast, and understand how these elements elevate barcodes from mere labels to indispensable tools in the realm of lab automation.

Symbology:

Selecting the right barcode symbology is critical for seamless identification. Symbologies like Code 128 or Data Matrix excel in encoding large data in a compact format, ideal for diverse lab items. 2D symbologies, like QR codes, offer enhanced data capacity and quick readability. Compatibility with scanning equipment and adherence to industry norms facilitate smooth integration, enhancing tracking efficiency within the lab environment.

Design:

Barcode design is pivotal for efficient workflows. Proper scaling, size adherence, and clear quiet zones are essential for readability. Consistent scaling prevents distortion, while clear quiet zones ensure accurate scanning. A well-designed barcode aligns with industry standards and symbology requirements, tailoring it to the lab’s specific needs for reliable and precise identification.

Sequence:

Managing barcode sequences is vital for error-free workflows. Duplication or inconsistency in sequences can disrupt processes, leading to misidentification and data errors. Implementing a robust system for generating and tracking unique identifiers, with customization options for relevant information, enhances traceability and data management. Leveraging barcode software with sequence validation and uniqueness checks prevents errors, optimizing efficiency, accuracy, and traceability.

Contrast:

Achieving a high-contrast barcode in automated labs involves thoughtful choices in color, label materials, and printing substances. The durability of labels and resistance to environmental factors, such as chemicals and fluctuating temperatures, are crucial considerations. Investing in quality materials and inks ensures barcode clarity over time, preserving the precision and reliability of automated workflows.

As we pivot to our next building block, scanning, remember that the simplicity of a barcode belies its profound impact on the efficiency and accuracy of automated laboratory processes.

Barcode Scanners

Now, let’s shift our focus to the symbiotic counterpart of barcodes – scanning. In the world of lab automation, where information flows seamlessly between physical entities and digital systems, the ability to capture and interpret barcode data is paramount.

Analytical instruments are frequently equipped with built-in barcode scanners, seamlessly integrating identification processes into analytical workflows. Additionally, stationary scanners strategically positioned along lab workflows enable samples to pass by, ensuring swift and accurate data capture at key points.

Moreover, the versatility of handheld scanners provides labs with the flexibility to capture barcode data in various settings, adding a layer of convenience to the intricate processes of sample tracking and data management.

The accuracy of scanning plays a pivotal role in preventing errors within the laboratory environment. A successful scan, free from inaccuracies, minimizes the risk of misidentifications, ensuring that the data captured aligns precisely with the intended information. This not only safeguards the integrity of results but also mitigates the potential for errors that could disrupt automated processes.

Once a compatible scanner, adept at reading your chosen barcode symbology, is in place, the efficiency and accuracy of the scanning process become paramount in the intricate web of lab automation. The groundwork laid by the quality of the barcode, as discussed in the previous chapter, becomes a critical component.

However, the success of scanning is a multifaceted interplay involving the scanner’s accuracy, speed, as well as the strategic placement of barcodes on the sample container. Let’s delve into these three key factors that collectively determine the efficacy of scanning in the context of lab automation.

Accuracy:

This refers to the scanner’s ability to correctly read and interpret the information encoded in a barcode. A highly accurate scanner minimizes the risk of errors, ensuring that the data captured from the barcode is reliable and matches the intended information. In a laboratory setting where precision is paramount, the accuracy of a scanner becomes a cornerstone in maintaining data integrity and minimizing the likelihood of disruptions in automated workflows.

Speed:

Pertaining to how quickly the barcode scanner can capture and process the barcode data, speed is of the essence in the fast-paced environment of lab automation. Faster scanning speeds are particularly advantageous when a large number of items need to be identified and tracked rapidly. This acceleration contributes to increased efficiency and productivity, allowing laboratories to handle high-throughput scenarios with seamless precision.

Label Placement/Application:

The art of label application is a critical determinant in the scanning process. If a label is applied crooked, in the wrong spot, or if it wrinkles, folds, or tears during application, the scan may fail. This failure is not due to the quality of the barcode, the scanner, or the label itself but arises from the imperfections in label application. Achieving precision label placement manually is a monumental challenge for technicians, given the complexity of labware and the meticulous demands of automation workflows.

The accuracy and speed of scanners, coupled with precise label placement, become integral components in the dance of laboratory automation, optimizing efficiency and reliability.

Automated Labelers

Proper labeling is crucial in the seamless functioning of an automated laboratory. Misplaced or inconsistent labels can lead to significant issues. Automated labelers, however, offer a solution that ensures unmatched consistency and precision, an achievement difficult to attain through manual labeling. Let’s explore how automated labelers fit into the landscape of automation integration.

Fully Automated or Semi-Automated:

Automated labelers come in both fully automated and semi-automated variants, allowing flexibility in integration with existing workflows. Semi-automated labelers involve some level of operator involvement, providing a balance between automation and manual control.

Compatible Label Materials:

It’s important to note that automated labelers require compatible label materials to function optimally. Choosing the right label materials is another variable in the integration landscape that warrants careful consideration.

As we conclude our exploration of the foundational building blocks in the intricate dance of lab automation it becomes evident that these elements serve as the bedrock for streamlined workflows, error prevention, and robust data traceability. The precision of barcodes, coupled with the efficiency of scanners, sets the stage for the integration of advanced technologies that propel laboratories toward unparalleled efficiency and accuracy.

Instrument and Hardware Integration

In the realm of automation, your analytical instruments are the workhorses of discovery. However, their true potential is unlocked when they can effortlessly communicate and collaborate with one another. This requires compatibility on multiple fronts.

First and foremost, hardware compatibility ensures that your instruments not only physically fit together but also function seamlessly.

When your autosampler, for instance, smoothly interfaces with your liquid handling system it eliminates bottlenecks in your workflow, enhancing efficiency and throughput while reducing errors.

Analyzers and Instruments:

To ensure seamless integration of your advanced analytical instruments, such as mass spectrometers, chromatographs, and spectrophotometers, into your laboratory automation system, utilizing barcodes is essential to harmonize data and facilitate integration with the rest of your lab equipment.

Compatibility: Ensure that analytical instruments are compatible with each other and with data management systems including LIMS, barcode scanners, and other sample management systems.

Data Flow: Establish a seamless data flow from these analyzers to data storage and analysis software, avoiding bottlenecks.

Barcode Integration: Implement barcoding solutions to uniquely identify samples and associate generated data with the correct samples.

Laboratory Robotics:

Robotic systems, like automated liquid handlers, are the linchpin of a fully integrated laboratory. When seamlessly combined with barcodes and scanners, precision labels and efficient scanning guide these systems in accurately handling samples, streamlining workflows, and reducing errors.

Workflow Coordination: Integrate robotic systems with sample management equipment to ensure efficient sample handling, transfer, and storage.

Data Synchronization: Establish real-time data synchronization between robotic systems and sample management equipment for accurate sample tracking.

Sample Tracking: Implement barcode labeling on sample containers and integrate barcode scanners with robotic systems for precise sample tracking.

Calibration and Maintenance:

One often overlooked facet of laboratory integration is the seamless incorporation and tracking of calibration and maintenance processes. Regular instrument calibration and maintenance can be integrated into the overall automation system, ensuring data accuracy and reducing downtime.

Scheduled Maintenance: Integrate maintenance schedules to ensure instruments are regularly serviced and calibrated, preventing downtime.

Calibration Data: Automatically record calibration data and store it centrally, aiding quality control and compliance.

Maintenance Alerts: Implement automated alerts for upcoming maintenance tasks based on instrument usage and predefined schedules.

The successful integration of analyzers, robotic systems, and data storage units not only optimizes workflows but also upholds the foundational principles of barcodes and scanning, ensuring precision and accuracy in every step of the analytical process.

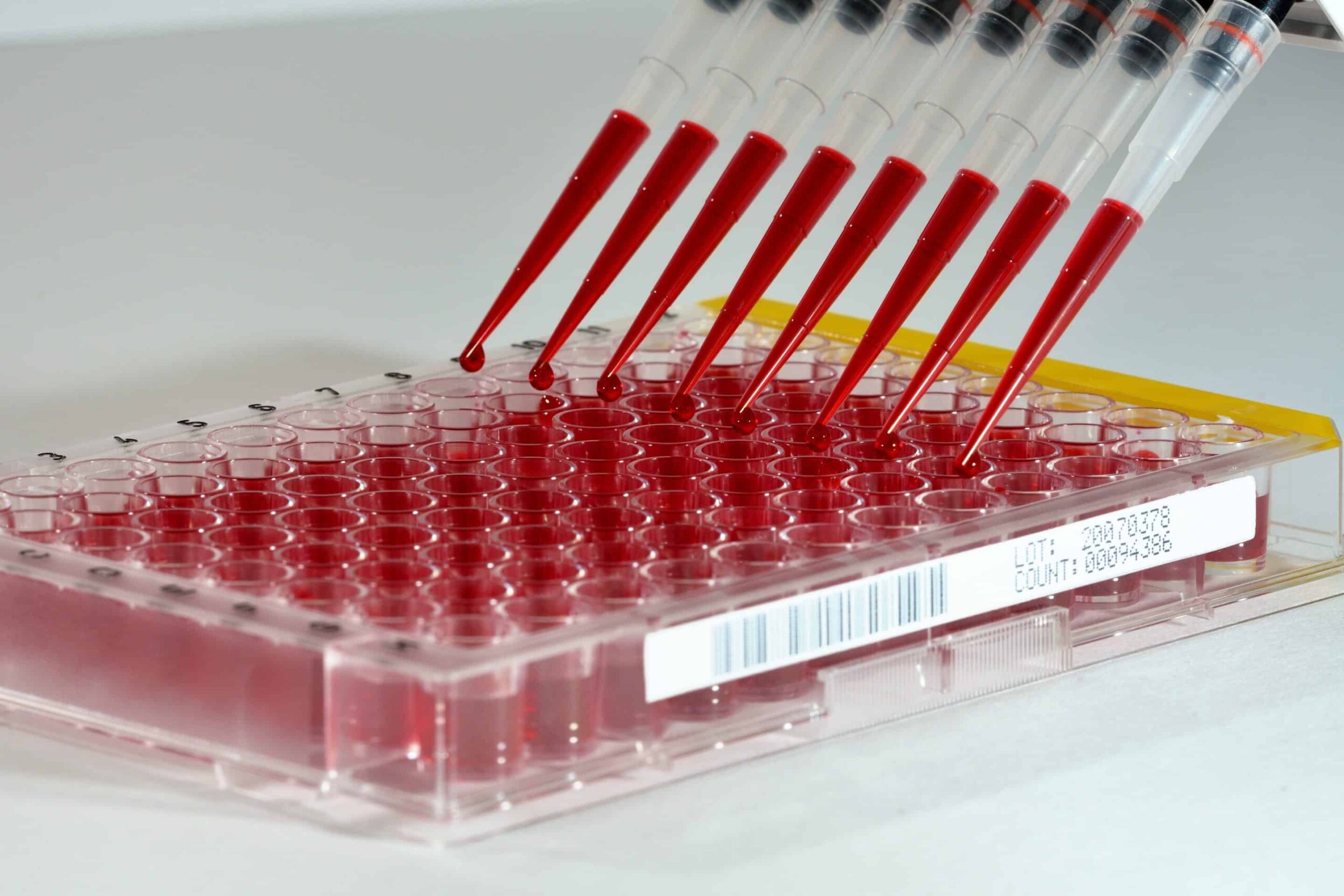

Lab Scenario: Plate Readers in High-Throughput Screening

Barcodes play a pivotal role in optimizing the performance of plate readers during high throughput screening (HTS) by efficiently managing sample identification and tracking. While the primary function of plate readers is to conduct optical and chemical measurements on samples, barcodes enhance this process by associating unique identifiers with entire microplates or specific plate sections.

As the microplate undergoes analysis, the barcode scanner seamlessly integrates with the plate reader, automating the identification of samples and ensuring precise correlation of data with the corresponding set of samples within the plate or plate section.

This systematic approach not only improves workflow efficiency and reduces errors but also aligns with the plate reader’s core functions, making it an invaluable tool for businesses focused on identification and tracking solutions during large-scale screening experiments.

Data and Software Integration

With our instruments and hardware harmonized, our journey through the integration landscape continues into the realm of Data Integration. In this phase, we explore how laboratories can effectively manage, harmonize, and utilize the wealth of data generated by the integrated instruments. Join us as we delve into the strategies and technologies that pave the way for a cohesive and data-driven laboratory environment, seamlessly building upon the foundation of successful Instrument and Hardware Integration.

As we navigate the digital landscape of laboratory automation, Data Integration takes center stage, aiming to harmonize the wealth of information generated by integrated instruments and hardware. In this phase, the focus shifts from physical components to the intelligent management and utilization of data, enriching laboratory operations and insights.

Data Carriers:

In the realm of automation integration, selecting the right data carriers is fundamental. Barcodes and RFID (Radio-Frequency Identification) tags stand as the primary choices for uniquely identifying samples, instruments, and equipment within the laboratory environment. To ensure seamless integration, labs should adopt a cohesive approach that allows these data carriers to work together harmoniously. This involves selecting barcode symbologies that can coexist with RFID technology, ensuring compatibility. By doing so, data carriers can communicate effectively with both automated systems and manual data entry methods, bridging the gap between the digital and physical realms.

Data Entry:

Efficient data entry methods are at the core of automation integration, as they bridge the human-computer interaction gap. While automation is crucial, some degree of manual data entry is often inevitable.

To optimize integration, labs should provide user-friendly interfaces for manual data entry, emphasizing accuracy and completeness.

Simultaneously, automated data capture methods, such as barcode scanning and RFID reading, should seamlessly integrate with the data entry process, ensuring data carriers communicate effectively with the data management system. Cross-training personnel to proficiently use multiple data entry methods further enhances compatibility and reduces errors.

Data Capture:

Within an automated workflow, data capture is the moment when samples move seamlessly through the system, and their corresponding barcode or RFID tag is read. This process is essential for real-time data integration and automation success. To achieve this, labs should implement workflow integration points where automated data capture occurs.

Real-time data flow mechanisms should be in place, facilitating the immediate transfer of data from the point of capture to the data management system. Validation checks should be employed at data capture points to ensure that the captured data corresponds accurately to the intended sample or equipment.

By focusing on efficient data capture, labs can ensure that data carriers communicate seamlessly with automation systems and manual data entry, creating a unified data ecosystem.

Data Storage:

Effective data storage integration is vital for organizing, securing, and retrieving data in an automated laboratory. The primary objective is to eliminate data silos and foster a cohesive data environment. Centralized data repositories or cloud-based storage solutions should be integrated to ensure accessibility and scalability, thus breaking down data silos. Simultaneously, data security measures, including encryption, access controls, and robust backup strategies, should be in place to safeguard stored data. Data should be organized through indexing and categorization to enable efficient retrieval, ensuring that data carriers, such as barcodes and RFID tags, harmonize with data storage systems. This integration fosters data accessibility and seamless communication within the broader laboratory automation framework, promoting a collaborative and unified research environment.

Data Annotation and Documentation:

Annotation and documentation practices play a crucial role in adding context and meaning to data, making it understandable and interpretable.

To ensure integration, labs should focus on metadata annotation during data entry to describe data origin, experimental conditions, and context. Version control systems should be implemented to track changes and annotations made to data over time, fostering data compatibility and traceability. Collaborative annotation practices should be encouraged, allowing multiple researchers to contribute annotations and insights, creating a shared understanding of the data.

By integrating these annotation and documentation practices, labs enable effective communication between data, personnel, and automation systems within their research environment.

In the realm of Data Integration, the focus shifts from the physical to the digital, highlighting the need for meticulous data management and utilization. Join us as we navigate through the intricacies of Data Integration, exploring how laboratories can effectively harness the power of data to drive efficiency, insights, and innovation in the landscape of laboratory automation.

Lab Scenario: Automated Data Entry for HPLC Sequence Tables

The integration of barcodes into HPLC sequence tables streamlines the process of sample identification and tracking.

By scanning barcodes, laboratory personnel can effortlessly input sample information into the sequence table, automating the population of details such as sample names, injection volumes, and other parameters.

This automation not only enhances the accuracy of data but also expedites the analytical workflow. Additionally, barcodes contribute to instrument configuration by facilitating quick and error-free setup based on the encoded information, ultimately ensuring seamless integration of sample tracking solutions within the HPLC environment.

Workflow Integration

With our data seamlessly integrated, our exploration of laboratory automation now delves into Workflow Automation—a realm where the orchestration of processes becomes a key driver of efficiency and precision. This phase builds upon the foundation of successful Instrument and Hardware Integration and Data Integration, setting the stage for the automated orchestration of tasks, experiments, and analyses.

Workflow Automation Integration takes the reins in steering laboratory operations towards streamlined efficiency. It encompasses the seamless coordination of diverse tasks, ensuring that processes flow seamlessly from one stage to the next. This integration is not only about connecting instruments and managing data but also about orchestrating a symphony of activities that minimize manual intervention, reduce errors, and enhance overall productivity.

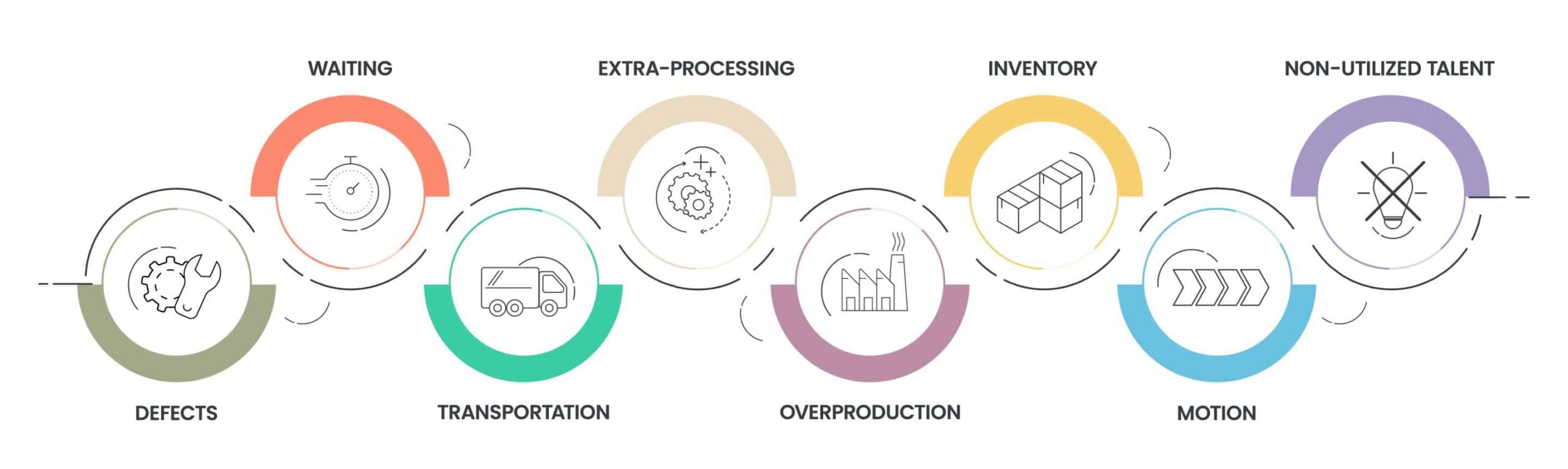

Methodologies:

In the pursuit of a seamlessly integrated laboratory environment, automation plays a pivotal role in harmonizing processes and optimizing efficiency. Three methodologies—Lean, Six Sigma, and GLP—can be seamlessly integrated into laboratory workflows to achieve methodical excellence and compliance while minimizing waste, including unnecessary motion and transportation.

Automation’s synergy with Lean principles creates a laboratory environment where efficiency thrives. For example, by automating material transportation within the laboratory, laboratories can significantly reduce the waste of motion and transportation. Robotic systems equipped with automation can transport samples or materials between workstations seamlessly, minimizing unnecessary movement by laboratory personnel.

Six Sigma methodologies, rooted in the pursuit of quality and consistency, find a natural home within integrated laboratory workflows. Automation provides real-time data collection and analysis, enabling laboratories to detect and address variations promptly. This reduces the waste of defects and rework, ensuring consistent and predictable outcomes.

For laboratories governed by GLP requirements, workflow integration is a critical element in maintaining data integrity and regulatory compliance. Automation-driven data capture and adherence to standardized operating procedures align seamlessly with GLP principles. This minimizes the waste of time spent on manual data entry and transportation of physical records, reinforcing the commitment to data quality and integrity.

Resource Optimization:

Efficient resource utilization is a key objective for laboratories seeking to maximize productivity while minimizing waste and costs. Resource optimization encompasses various aspects, from personnel and equipment to consumables and energy. Automation integration serves as a catalyst for achieving resource optimization by streamlining processes, reducing manual interventions, and ensuring that resources are utilized effectively.

Personnel Efficiency: Automation integration minimizes the need for manual, repetitive tasks, allowing laboratory personnel to focus on more complex and value-added activities. Automated workflows and robotic systems handle routine tasks, enabling scientists and technicians to dedicate their expertise to research, analysis, and innovation.

Equipment Utilization: Properly integrated automation ensures that laboratory instruments and equipment are optimally utilized. Synchronized workflows and automated scheduling ensure that equipment downtime is minimized, resulting in efficient use of high-value assets.

Consumable Management: Barcode-based consumable tracking and automation integration prevent overstocking or understocking of essential materials. Laboratories can monitor consumable usage in real time, enabling just-in-time procurement and reducing excess inventory costs.

Energy Efficiency: Environmental monitoring and automation controls help laboratories optimize energy usage. Automated systems can adjust environmental conditions based on occupancy, experiment requirements, and energy-saving protocols, reducing energy consumption and costs.

Space Utilization: Automation integration often results in more compact and efficient laboratory layouts. Automated storage systems, robotic platforms, and optimized workflow designs reduce the physical footprint required for operations, allowing laboratories to maximize space utilization.

Reporting:

In the modern laboratory landscape, data-driven insights and comprehensive reporting are vital components for informed decision-making, compliance, and quality assurance. Automation integration empowers laboratories to unlock the full potential of their data by streamlining reporting processes, ensuring data accuracy, and providing unprecedented real-time access to critical information. As a result, laboratories can now report on their entire laboratory environment, gaining a holistic understanding of how different processes impact one another, thanks to the seamless integration of data.

Unified Data Reporting: Automation integration ensures that data from various sources, including analytical instruments, sample management systems, and environmental monitors, is seamlessly collected, processed, and consolidated. This unified data environment simplifies reporting by eliminating the need to pull data from disparate systems. Laboratories can generate comprehensive reports, providing a holistic view of their operations. This transformation means laboratories are no longer hindered by data silos and can report on their lab as a whole.

Real-Time Reporting Revolution: Perhaps one of the most significant advancements in laboratory operations brought about by automation integration is real-time reporting. Laboratories often had to contend with delays of weeks or even months before receiving critical reports.

Automation-driven data capture and analysis have changed this paradigm. Scientists and technicians can now monitor experiment progress, sample status, and environmental conditions in real time.

This real-time insight enhances decision-making, allowing laboratories to respond promptly to deviations or issues, ultimately expediting research and innovation.

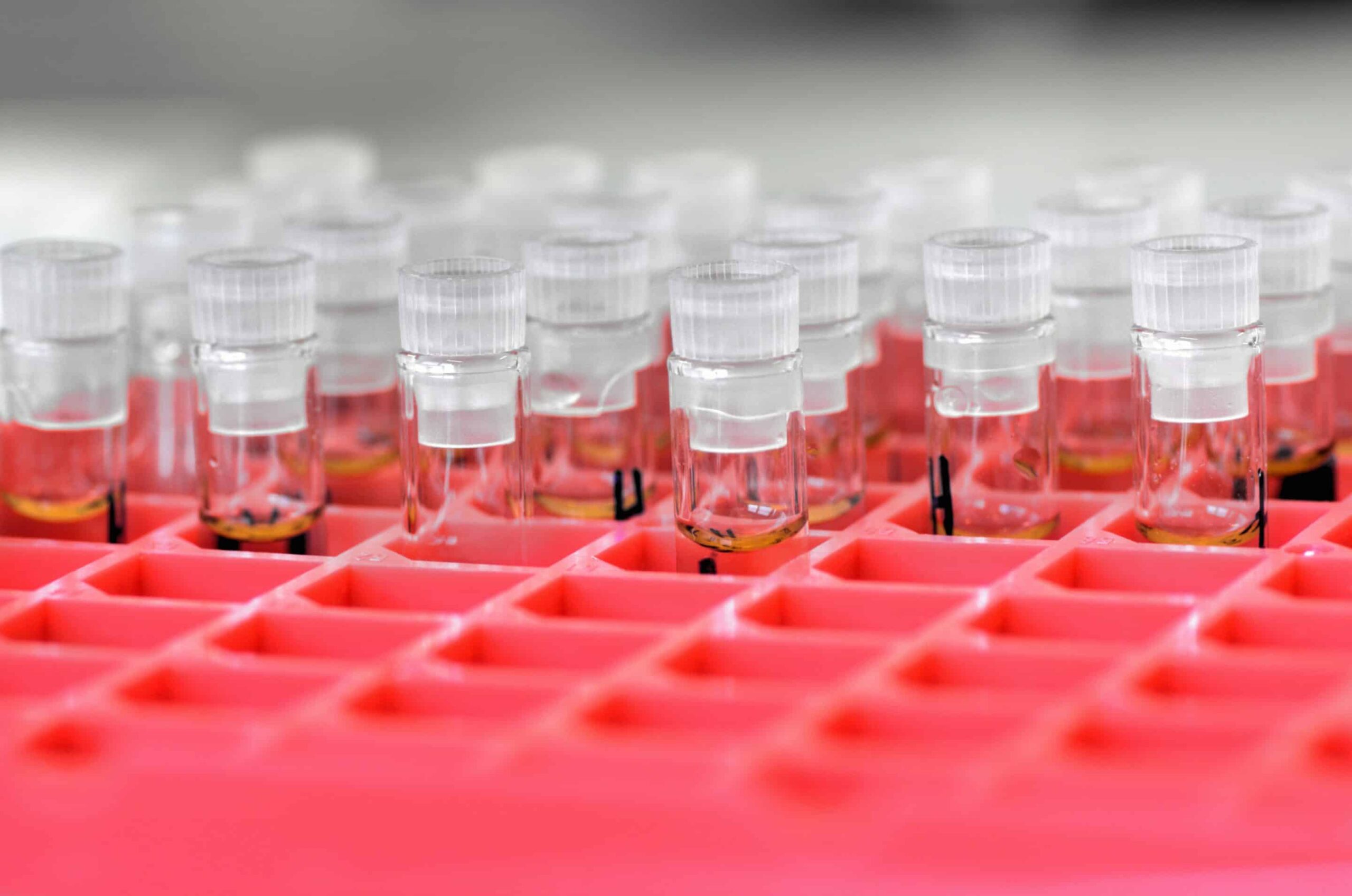

Lab Scenario: Automated Storage and Retrieval in Biobanks

In biobanks, barcodes are pivotal in supporting the automation of sample storage and retrieval systems. Each sample is assigned a unique barcode linked to crucial information. As samples enter the automated storage system, barcode data is integrated into the database, associating samples with specific locations. During retrieval, a robotic arm equipped with a barcode scanner precisely identifies and confirms the correct sample.

This barcode-based verification enhances accuracy and minimizes errors. The comprehensive traceability of barcode-scanned interactions ensures efficient data management and compliance with regulatory standards. Overall, barcodes play a central role in streamlining the identification, tracking, and retrieval of samples in biobanks, contributing to the efficiency and reliability of automated processes.

Automation Integration Checklist

To harness the full potential of laboratory automation, laboratories must approach integration as a holistic strategy. Successful integration involves the harmonious convergence of data, equipment, and workflows. Here are key guidelines to empower laboratories in crafting a robust and efficient laboratory automation ecosystem:

Embarking on the journey of automation integration is achievable by conducting streamlined audits that help laboratories assess their current state and identify areas for improvement:

- Sample Movement Assessment: Review how samples flow through your lab. How do you currently track the history of sample movement?

- Gaps and Blind Spots Identification: Identify areas with limited visibility or tracking capabilities. Where are the blind spots in our processes, and how can we improve data capture and monitoring?

- Data Audit: Assessing Data Management Practices: Conduct a data audit to understand and optimize your data management practices. Begin by asking:

- Where does your data come from? Identify all sources of data within your laboratory, including instruments, manual entry, and external systems.

- Do you have isolated data silos? Determine if your data is scattered across disconnected databases or systems. Explore opportunities to centralize and integrate data for a unified view.

- Time and Error Analysis: Analyze where you spend the most time and identify error-prone processes. Which manual tasks consume the most time, and how can we enhance accuracy and efficiency?

Simplifying Automation Integration: A Step-by-Step Approach:

Embarking on the journey of automation integration might seem like a complex task, requiring an in-depth analysis of your laboratory’s processes and data management. While it’s true that successful automation integration involves attention to detail, it doesn’t have to be overwhelming. In fact, it can be remarkably straightforward if approached methodically. The key lies in recognizing that the path to automation integration consists of manageable steps, and viewing it as a holistic endeavor rather than a disjointed series of tasks.

Begin with the foundational building blocks we’ve discussed, such as barcodes, scanning, and precise label placement. These elements serve as the cornerstones of automation, laying the groundwork for streamlined workflows and data management. From there, start asking essential questions about your data sources, tracking methods, and areas for improvement. This initial self-assessment helps identify areas where automation can provide the most significant benefits.

It’s important to remember that you don’t have to go it alone. Seeking assistance from a trusted automation partner can greatly simplify the process. Whether you require a customized, large-scale automated solution engineered to your specific needs or seek guidance on integrating existing systems, a knowledgeable partner can provide invaluable expertise. They work with you to ensure you have all the necessary tools and support for a smooth transition to automation integration.

In conclusion, while automation integration may initially appear complex, it can be made easy by taking it one step at a time and approaching it as a comprehensive endeavor. Start with the foundational elements, assess your data and tracking practices, and don’t hesitate to seek guidance from an experienced partner. With the right approach and support, automation integration becomes a manageable and rewarding journey toward enhanced efficiency and laboratory performance.

The integration journey is not just about connecting devices or managing data; it’s a holistic strategy that propels laboratories towards a future where scientific endeavors are streamlined, errors are minimized, and insights are amplified. Excellence in automation is not solitary; it’s a partnership. We stand ready to orchestrate this journey with you, offering expertise and solutions to ensure every note resonates with innovation, collaboration, and a commitment to scientific excellence. Together, we create the symphony of laboratory automation that reaches new heights, where the future is not just imagined but realized.

Connect with our labelling experts today

Blog article form

"*" indicates required fields